Ecos System Description GMK 4075: Error Codes [PDF]

Home page ECOS System Description GMK 4075 Error Codes Valid as of ECOS Version 2.00.00 Thomas Heidrich, Matthias Ma

47 0 505KB

Papiere empfehlen

![Ecos System Description GMK 4075: Error Codes [PDF]](https://vdoc.tips/img/200x200/ecos-system-description-gmk-4075-error-codes.jpg)

- Author / Uploaded

- Mohamed Rashed

Datei wird geladen, bitte warten...

Zitiervorschau

Home page

ECOS System Description GMK 4075

Error Codes

Valid as of ECOS Version 2.00.00

Thomas Heidrich, Matthias Macht, Michael Gerdes TK4, 19.12.2001

Contents 1

GENERAL DESCRIPTION .......................................................................................... 1 1.1 1.2

2

LIST OF DEVICES ........................................................................................................... 3 LIST OF GROUPS ............................................................................................................ 4

LIST OF COMPONENTS.............................................................................................. 6 2.1 DIGITAL INPUTS (GROUP NUMBER 1) ............................................................................ 6 2.1.1 Digital Inputs of ESX 0..4 ........................................................................................ 6 2.1.1.1Possible Errors............................................................................................................................. 7

2.1.2 Digital Inputs of IO Boards 0..3 .............................................................................. 7 2.1.2.1Possible Errors............................................................................................................................. 9

2.2 ANALOGUE INPUTS (GROUP NUMBER 2) ....................................................................... 9 2.2.1 Analogue Inputs of ESX 0..4 .................................................................................... 9 2.2.1.1Possible Errors........................................................................................................................... 10

2.2.2 Analogue Inputs of IO Boards 0..3 ........................................................................ 10 2.2.2.1Possible Errors........................................................................................................................... 11

2.3 OUTPUTS (GROUP NUMBER 3)..................................................................................... 11 2.3.1 Outputs of ESX 0..4................................................................................................ 11 2.3.1.1Possible Errors........................................................................................................................... 12

2.3.2 Outputs of IO Boards 0..3...................................................................................... 13 2.3.2.1Possible Errors........................................................................................................................... 14

2.4 FAKE'S (GROUP NUMBER 4)....................................................................................... 15 2.4.1 FAKE’s of ESX 0..4................................................................................................ 15 2.4.1.1Possible Errors........................................................................................................................... 16

2.5 CONTROL LEVER ERRORS............................................................................................ 16 2.6 ECOS ERRORS (DEVICE NUMBER 25)......................................................................... 17 2.6.1 Change-over Contact Group (Group Number 12)................................................. 17 2.6.2 Locking System Group (Group Number 16) .......................................................... 18 2.6.2.1Explanations regarding Error Message 25.16.3.n...................................................................... 19

2.6.3 Carrier Group (Group Number 17)....................................................................... 20 2.6.4 System Monitoring Group (Group Number 18)..................................................... 20 2.7 CAN BUS ERRORS (GROUP NUMBER 6) ...................................................................... 21 3

ASSIGNMENT OF THE ESX ..................................................................................... 28

System Description GMK 4075 Error Codes

Page 1

1 General Description The ECOS offers the possibility of electrically monitoring the sensors, actuators and equipment connected to the system. Connected component being continuously checked for circuit integrity extends to solenoid valves, switches, proximity switches, sensors, external alarms, warning lamps, control panels, displays and CAN bus circuits etc. (see device list on page 3). The error message produced by the ECOS consists of four figures, which can be any value between 0 and 255. A new error message is indicated by a flashing warning triangle and can be displayed via the function key [?]. For carrier errors the error message structure is the same with error indication being from a dashboard (collective error) warning lamp. The respective error code can be read on the outrigger control panel. The number code is constructed as follows: XXX – XXX – XXX – XXX

Error number Index Group number Device number The allocation of device and group is the same for all error messages. Index and error number can be used as an extended error message for certain devices. In this case, no figure appears in the display for the index and/or no figure appears for the error number.

This flashing symbol on the superstructure ECOS display indicates a system error Pressing the enquiry button will then display the error message .

This illuminated symbol on the carrier dashboard indicates a carrier system error.

Example errors are shown on the following page

System Description GMK 4075 Error Codes

Page 2

Example superstructure errors:

007

1

1

1

4

Device Number

Group Number

Index

Error Number

Device

Group

#1

Error

ESX0

Digital input

IN3503

Short to ground

Example carrier errors:

Example: 1

9

3

13

2

Example: 2

The errors can be read out on the outrigger control panel. You press F1 and 1/5 buttons both together. Then a display view is shown as example 1- ALL ERR 3: indicating 3 ECOS errors on the system. Pressing All STABILIZERS DOWN will then show the actual error in four numbered elements. The numbers are read: top left – top right – bottom left – bottom right as example 2, and make up error code 9-3-13-2. To get the next error message press ALL STABILIZERS UP. With UP and DOWN arrows you can scroll through the error messages. To return to the normal display you press buttons F1 and 1/5 both together. To clear the error display you must restart the system.

System Description GMK 4075 Error Codes

Page 3

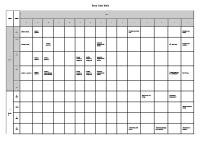

1.1 List of Devices Device No. Device

Fig.

Device No. Device

Fig.

1

ESX 0

17

Left control lever

2

ESX 1

18

Right control lever

3

ESX 2

19

4

ESX 3

20

5

ESX 4

21

9

IO 0

22

RCI

(EKS4)

(Rated Capacity Indicator) Cable length sensor (Precision length sensor) Display MMI 1 (Outrigger control panel 1) MMI 2

10

IO 1

23

11

IO 2

24

Inclination senor

12

IO 3

25

ECOS

Outrigger control panel 2)

System Description GMK 4075 Error Codes

1.2 List of Groups Group No.

Group

Fig.

Notes

1

Digital input

see Chapter 2.1, page 6

2

Analogue input

see Chapter 2.2, page 9

3

Output

see Chapter 2.3, page 11

4

FAKE

see Chapter 2.4, page 15

5

Sequences

not currently being used

6

CAN bus

see Chapter 2.7, page 21

7

Virtual earth

not currently being used

8

Vcc permanent

not currently being used

9

Vcc clock pulse

not currently being used

10

Vcc 8.5V

not currently being used

11

Total current

not currently being used

12

Change-over contact

see Chapter 2.5, page 16 see Chapter 2.6.1, page 17

13

Stepping switch

not currently being used

14

Axis X

see Chapter 2.5, page 16

Page 4

System Description GMK 4075 Error Codes

15

Axis Y

see Chapter 2.5, page 16

16

Pinning system

see Chapter 0, page 18

17

Carrier

see Chapter 2.6.3, page 20

18

System monitoring

see Chapter 2.6.4, page 20

Page 5

System Description GMK 4075 Error Codes

Page 6

2 List of Components 2.1 Digital Inputs (Group Number 1) 2.1.1 Digital Inputs of ESX 0..4 Device Number 1

2

3

4

5

1

IN3503

S2101P

FREE

J3502_8

S4703M

2

S1101P

S2102P

FREE

J3502_9

S4704M

3

S1201P

S2110N

S2308T

J3502_10

S4705N

4

A1201_14

S2111N

S2301P

J3502_11

S4154M

5

A1101_6

S2112N

S2201P

J3501_8

S4155M

6

A1201_6

S2113N

S2201N

J3501_9

S4105M

7

A1101_3

S2114N

S2202N

J3501_10

S4101M

8

A1101_4

S2115N

S2203N

J3501_11

S4102M

9

A1201_3

S2116N

S2204N

J3502_16

S4103M

10

A1201_4

S2117N

S2205N

S1202

S4104M

11

S3520

FREE

S2206N

S2102

S4106P

12

J3503_gn

FREE

S2207N

S2103

IN4410

13

J3503_bl_or

FREE

S2208N

S2104

IN4409

14

IN3504

FREE

S2209N

S2304

IN3602

Index

System Description GMK 4075 Error Codes

Page 7

15

S3523

S3524

S2210N

S3710

FREE

16

S3522

S3525

S3527

J3501_16

FREE

2.1.1.1 Possible Errors Error No.

Fig.

Error

Description

2

Cable break

Connection/cable continuity is defective

3

Short circuit to Vcc

Input short circuit to battery + (UB)

4

Short circuit to ground

Input short circuit to ground

9

ADC value does not suit Internal error in ESX module digital level

10

Undefined status

Incorrect input values: the measured value does not match internal recognition values

11

Initialising software

Internal software errors

2.1.2 Digital Inputs of IO Boards 0..3 Device Number 9

10

11

12

1

S4301

S4301N

S4305N

S3501

2

S4302

S4302N

S4306N

S3502

3

S4303

S4303N

S4307N

S3702_24

4

S4304

S4304N

S4308N

S3702_44

5

S4305

-

-

S4804

6

S4306

-

-

-

Index

System Description GMK 4075 Error Codes

Page 8

7

S4307_7

-

-

S4205

8

S4308

-

-

-

9

S4307_1

-

-

S4204

10

S4704

-

-

-

11

S4702_7

-

-

J3502_6

12

S4702_2

-

-

J3502_5

13

-

FREE

FREE

J3502_17

14

S4104

FREE

FREE

J3501_6

15

S4105

FREE

FREE

J3501_5

16

-

FREE

FREE

J3501_17

17

-

-

-

FREE

18

-

-

-

FREE

19

-

-

-

FREE

20

-

-

-

FREE

21

K3602

-

-

FREE

22

-

-

-

FREE

23

FREE

-

-

FREE

24

FREE

-

-

FREE

System Description GMK 4075 Error Codes

Page 9

2.1.2.1 Possible Errors Error No.

Fig.

Error

Description

2

Cable break

Connection/cable continuity is defective

3

Short circuit to Vcc

Input short circuit to battery + (UB)

4

Short circuit to ground

Input short circuit to ground

2.2 Analogue Inputs (Group Number 2) 2.2.1 Analogue Inputs of ESX 0..4 Device Number 1

2

3

4

5

1

IN3503a

FREE

FREE

J3502_3

S0240T

2

IN2401

FREE

FREE

J3502_4

S0209Q

3

IN3709

FREE

FREE

J3501_3

FREE

4

FREE

S3501P

FREE

J3501_4

FREE

5

J3503_rs

S2103P

S2302P

IN2301

FREE

6

FREE

FREE

FREE

M0101

FREE

7

-

-

-

-

-

8

-

-

-

-

-

Index

System Description GMK 4075 Error Codes

Page 10

2.2.1.1 Possible Errors Error No.

Fig.

Error

Description

3

Short circuit to Vcc

Short to battery

7

Below minimum threshold value

Defective sensor, cable break or short to ground are all possible causes

8

Above maximum threshold value

Defective sensor or short to battery are both possible causes

13

Function call software

Internal software error

2.2.2 Analogue Inputs of IO Boards 0..3 Device Number 9

10

11

12

1

FREE

S4405P

S4407P

FREE

2

FREE

S4406P

S4408P

FREE

3

FREE

FREE

FREE

FREE

4

FREE

FREE

FREE

FREE

5

FREE

FREE

FREE

FREE

6

FREE

FREE

FREE

FREE

7

FREE

FREE

FREE

FREE

8

FREE

FREE

FREE

FREE

9

FREE

FREE

FREE

FREE

10

FREE

FREE

FREE

FREE

Index

System Description GMK 4075 Error Codes

Page 11

11

FREE

FREE

FREE

FREE

12

FREE

FREE

FREE

FREE

2.2.2.1 Possible Errors Error No.

Fig.

Error

Description

7

Below minimum threshold value

Defective sensor, cable break or short to ground are all possible causes

8

Above maximum threshold value

Defective sensor or short to battery are both possible causes

Note: the display may erroneously show error no 4 with corresponding graphic (short to ground) but the meaning is as error no 7 above.

2.3 Outputs (Group Number 3) 2.3.1 Outputs of ESX 0..4 Device Number 1

2

3

4

5

1

Y1107

Y2105

Y2301

B3401

Y4709

2

Y1207

Y2120

Y2302

J3501_13

Y4123

3

Y2108

Y2121

Y2307

J3502_13

Y4124

4

Y2107

Y2106

Y2403

H3703

Y4704

5

Y3403

FREE

Y2308

B3702

Y4731 Y4732

6

Y1104

Y2130

Y2401

H2304

OUT3600

7

Y1204

Y2131

Y2402

H1102

OUT3601

8

FREE

Y2133

Y2304

H1202

OUT3602

Index

System Description GMK 4075 Error Codes

Page 12

9

Y1101

Y2101

M0102

FREE

Y4710

10

Y1102

Y2102

M0103

-

Y4711

11

Y1202

Y2103

Y2202

-

Y4702

12

Y1201

Y2104

Y2203

-

Y4703

13

Y1105

FREE

Y2201

H2104

Y4701

14

Y1205

FREE

-

H2102

Y4105

15

Y3401

Y2132

FREE

H2103

Y4721 Y4722

16

Y3402

Y2134

Y2204

H2301

Y4104

17

Vcc clock pulse

Vcc clock pulse

Vcc clock pulse

Vcc clock pulse

Vcc clock pulse

18

Vcc perm.

Vcc perm.

Vcc perm.

Vcc perm.

Vcc perm.

2.3.1.1 Possible Errors Error No.

Fig.

Error

Description

2

Cable break

Connection/cable continuity is defective

3

Short circuit to Vcc

Output short circuit to battery + (UB)

4

Short circuit to ground

Output short circuit to ground

System Description GMK 4075 Error Codes

Page 13

2.3.2 Outputs of IO Boards 0..3 Device Number 9

10

11

12

1

-

-

-

-

2

-

-

-

-

3

-

-

-

-

4

-

-

-

-

5

-

Y4301A

Y4305A

-

6

-

Y4301B

Y4305B

H4806

7

-

Y4301C

Y4305C

-

8

-

Y4301D

Y4305D

H4205

9

-

Y4302A

Y4306A

-

10

-

Y4302B

Y4306B

H4204

11

-

Y4302C

Y4306C

-

12

-

Y4302D

Y4306D

-

13

H4106

FREE

FREE

-

14

-

FREE

FREE

-

15

-

FREE

FREE

-

16

H3601

FREE

FREE

-

Index

System Description GMK 4075 Error Codes

Page 14

17

H4104

Y4402

Y4404

FREE

18

H4105

Y4406

Y4408

FREE

19

H4303

Y4421

Y4441

FREE

20

H4706

Y4461

Y4481

FREE

21

K3602

Y4401

Y4403

FREE

22

OUT4301

Y4405

Y4407

FREE

23

FREE

Y4411

Y4431

FREE

24

FREE

Y4451

Y4471

FREE

2.3.2.1 Possible Errors Error No.

Fig.

Error

Description

2

Cable break

Connection/cable continuity is defective

3

Short circuit to Vcc

Output short circuit to battery + (UB)

4

Short circuit to ground

Output short circuit to ground

System Description GMK 4075 Error Codes

Page 15

2.4 FAKE's (Group Number 4) 2.4.1 FAKE’s of ESX 0..4 FAKE: Output which is used as an input Device Number 1

2

3

4

5

1

-

-

-

-

-

2

-

-

-

-

-

3

-

-

-

-

-

4

-

-

-

-

-

5

-

FREE

-

-

-

6

-

-

-

-

-

7

-

-

-

-

-

8

FREE

-

-

-

-

9

-

-

-

FREE

-

10

-

-

-

S3401_7

-

11

-

-

-

S3401_1

-

12

-

-

-

S1102

-

13

-

FREE

-

-

-

14

-

FREE

S3526

-

-

15

-

-

FREE

-

-

Index

System Description GMK 4075 Error Codes

Page 16

16

-

-

-

-

-

17

-

-

-

-

-

18

-

-

-

-

-

2.4.1.1 Possible Errors Error No.

Fig.

Error

Description

2

Cable break

Connection/cable continuity is defective

3

Short circuit to Vcc

Input short circuit to battery + (UB)

4

Short circuit to earth

Input short circuit to ground

2.5 Control Lever Errors Device No.

Fig.

Group

Index

No. Fig.

Error

Description

No. Fig. Both contacts switched (rocker switch)

17

12

0

14

17

14

0

14

17

14

1

14

Current value >10% or < -10% but no directional contact

17

14

2

14

Current value negative, directional contact positive

17

14

3

14

Current value positive, directional contact negative

17

15

0

14

17

15

1

14

Current value >10% or < -10% but no directional contact

17

15

2

14

Current value negative, directional contact positive

Both directional contacts switched

Both directional contacts switched

System Description GMK 4075 Error Codes Current value positive, directional contact negative

17

15

3

14

18

12

0

14

18

14

0

14

18

14

1

14

Current value >10% or < -10% but no directional contact

18

14

2

14

Current value negative, directional contact positive

18

14

3

14

Current value positive, directional contact negative

18

15

0

14

18

15

1

14

Current value >10% or < -10% but no directional contact

18

15

2

14

Current value negative, directional contact positive

18

15

3

14

Current value positive, directional contact negative

Both contacts switched (rocker switch) Both directional contacts switched

Both directional contacts switched

2.6 ECOS Errors (Device Number 25) 2.6.1 Change-over Contact Group (Group Number 12) Device No. 25

Fig.

Group

Index

No. Fig. 12

Error

Description

No. Fig. 0

14

Both directional contacts switched (Tilt cab)

Page 17

System Description GMK 4075 Error Codes

Page 18

2.6.2 Locking System Group (Group Number 16) Device No.

Group

Index

Error

Description

Fig.

25

16

0

0

25

16

1

4

25

16

1

5

25

16

2

1

25

16

2

2

25

16

2

3

25

16

2

4

25

16

3

n

Error of the EKS4 length sensor for the telescoping cylinder length - The redundant length control (comparison of ECOS length with EKS4 length) is no longer operating, resulting in losses in the system safety of the telescoping system Error in comparing the ECOS length with the EKS4 length - The difference in the two lengths has exceeded the tolerance threshold (set by service software), i.e. one of the two length sensors is emitting an invalid value - Semi- and fully automatic operation are no longer functioning; the locking system can only be operated in emergency operation - During emergency operation the current length of the ECOS length sensor and the EKS4 length sensor are displayed; a decision has to be made as to which length information is correct Error in controlling the telescoping cylinder movement - It was established that the current direction of movement of the telescoping cylinder contradicts the telescoping system’s operating status (e.g. retracting direction of movement and extending operating status) - Semi- and fully automatic operation are no longer functioning; the locking system can only be operated in emergency operation Error in controlling the telescopic status - The telescopic status is inconclusive in itself (e.g. more than one telescope section unlocked) - All the functions of the telescoping system are blocked; a valid telescopic status must first be input or a change made to emergency operation Error in controlling the telescopic status - The position of the telescoping cylinder in connection with the telescopic status contradicts the locking system’s operating status (is only evaluated in TLSL operating status) - All the functions of the telescoping system are blocked; a valid telescopic status must first be input or a change made to emergency operation Error in controlling the telescopic status - The current telescopic status contradicts the locking system’s current operating status (e.g. TLSU operating status, however according to telescopic status no telescope section is unlocked) - All the functions of the telescoping system are blocked; a valid telescopic status must first be input or a change made to emergency operation Error in controlling the telescopic status - The proximity switches’ signals for detecting the position of the telescoping cylinder (S2116N, S2117N) contradict the locking system’s current operating status (e.g. TLSU operating status, however none of the proximity switches has switched) - All the functions of the telescoping system are blocked; a valid telescopic status must first be input or a change made to emergency operation Error in detecting the locking status - The evaluation of the proximity switches’ signals for detecting the locking status (S2110N – S2115N) produces an invalid status - Semi- and fully automatic operation are no longer functioning; the locking system can only be operated in emergency operation - The error number 'n' indicates which proximity switches (S2110N - S2115N) were switched at the time the error occurred - See explanations regarding this in chapter 2.6.2.1

System Description GMK 4075 Error Codes

25

16

4

0

Page 19

Error in the unlocking mechanism - The wrong pins were released during an unlocking request (e.g. request for the telescoping cylinder to be unlocked, but the telecope section was unlocked) - Presumed error: valve Y2130 for switching over unlocking between telecoping cylinder and telescope section is sticking. - Semi- and fully automatic operation are no longer functioning; the locking system can only be operated in emergency operation

2.6.2.1 Explanations regarding Error Message 25.16.3.n Error message 25.16.3.n (device = ECOS, group = locking system) denotes an error during the detection of the current locking status. The evaluation of the signals of proximity switches S2110N to S2115N produces an invalid condition. The error number of this error message (designated here by 'n') reflects the switched condition of these proximity switches at the time the error occurred. Determining the switched conditions of the proximity switches from the error number 'n': The proximity switches have various weightings, which are as follows: S2114N (tele-cyl. lock. left)

→

Weighting

=

1

S2115N (tele-cyl. lock. right)

→

Weighting

=

2

S2112N (tele-cyl. unlock. left)

→

Weighting

=

4

S2113N (tele-cyl. unlock. right)

→

Weighting

=

8

S2111N (boom section locked)

→

Weighting

=

16

S2110N (boom section unlocked)

→

Weighting

=

32

In order to now determine the proximity switches’ switched conditions from the error number 'n', the error number 'n' is split up into the sum of the proximity switches’ weightings. If the sum includes a weighting, this means that the proximity switch belonging to this weighting was switched at the time the error occurred. All proximity switches, the weightings of which are not included in the sum, were not switched. Example: Error Message = 25.16.3.33 → Error number n = 33 → 33 = 32 + 1, the error number n = 33 includes weightings 32 and 1 → at the time the error occurred only proximity switches S2110N and S2114N were switched. Note: if the error message =25.16.3.0 it means that without a weighting no switches were active.

System Description GMK 4075 Error Codes

Page 20

2.6.3 Carrier Group (Group Number 17) Device No.

Group

Index

Error

Description

Fig.

25

17

0

0

25

17

0

1

Error during the initialisation of the separate steering - Crane operating status invalid or the limit switches’ signals for detecting the status of the separate steering idler (S4703M, S4704M) are not conclusive - Separate steering not functioning; check that ignitions and superstructure change-over switches have been set correctly, then check the limit switches’ signals Error in input signals to separate steering - The limit switches’ signals for detecting the status of the separate steering idler (S4703M = low, S4704M = high) are not conclusive - Check the limit switches’ signals

2.6.4 System Monitoring Group (Group Number 18) valid for devices No. 1 to 5 to Device

Group

Index

Error

1..5

18

0

1

1..5

18

0

2

1..5

18

0

3

1..5

18

0

4

1..5

18

0

5

1..5

18

0

6

1..5

18

0

7

1..5

18

0

8

Description Error in the control system’s start phase • The earth connection to the housing of the relevant ESX is not OK • The housing’s earthing should be checked. Error in the control system’s start phase • One of the outputs of the relevant ESX has a connection to the supply voltage. Error in the control system’s start phase • The initiating current of the output VCC clock pulse is greater than 3 ampere. • A component at the Vcc clock pulse connection is causing a short circuit Error in the control system’s start phase • The initiating current of the output VCC perm. is greater than 3 ampere. • A component at the Vcc perm. connection is causing a short circuit Operating error • The output current of the output VCC clock pulse was greater than 10 ampere. • A component at the Vcc clock pulse connection is causing a short circuit Operating error • The total of all of the VCC perm. output current was greater than 10 ampere. • A component at the Vcc perm. connection is causing a short circuit Operating error • The total of all the output currents was greater than 28 ampere. Operating error • The 8.5V output voltage is outside the tolerance. • A component at the 8.5V connection is causing a short circuit, or the control system is defective.

System Description GMK 4075 Error Codes 1..5

18

0

9

1..5

18

0

10

Page 21

Operating error • Slave has detected failure of the CAN masters. • The CAN bus connection should be checked. Operating error • The control system’s output drivers are not supplied with voltage. • Check fuses and supply voltage.

2.7 CAN Bus Errors (Group Number 6) Device No.

Fig.

Group

Index

Error

Description

No. Fig.

1

6

0

0

1

6

1

0

1

6

1

1

1

6

1

2

1

6

1

3

1

6

1

4

1

6

1

5

1

6

1

6

The CAN bus connection from ESX 3 to ESX 0 was lost within the process phase - The superstructure can no longer be operated from the cab The emergency operation box is to be used to de-rig the crane The CAN bus connection from ESX 3 to ESX 0 was lost within the configuration phase - The superstructure can no longer be operated from the cab The emergency operation box is to be used to de-rig the crane Error within the configuration phase: ESX 0 is a control system from another type of crane - The connection to ESX 0 is lost - The superstructure can no longer be operated from the cab The emergency operation box is to be used to de-rig the crane Error within the configuration phase: ESX 0 has the wrong version of software - The connection to ESX 0 is lost - The superstructure can no longer be operated from the cab The emergency operation box is to be used to de-rig the crane Error within the configuration phase: ESX 0 has a serial number, however the EEPROM data is not valid - The connection to ESX 0 is lost - The superstructure can no longer be operated from the cab The emergency operation box is to be used to de-rig the crane Error within the configuration phase: ESX 0 has an incorrect serial number - The connection to ESX 0 is lost - The superstructure can no longer be operated from the cab The emergency operation box is to be used to de-rig the crane Error within the configuration phase: The CAN bus connection from ESX 3 to ESX 0 was lost during the transition of ESX 0 to the STOP mode - The superstructure can no longer be operated from the cab The emergency operation box is to be used to de-rig the crane Error within the configuration phase: The configuration data from ESX 0 could not be fully received. - The superstructure can no longer be operated from the cab The emergency operation box is to be used to de-rig the crane

System Description GMK 4075 Error Codes

1

6

Device No.

Fig.

Group

2

0

Index

Error

Page 22

The CAN bus connection from ESX 3 to ESX 0 was lost during the transition from the configuration phase to the process phase - The superstructure can no longer be operated from the cab The emergency operation box is to be used to de-rig the crane

Description

No. Fig.

2

6

0

0

2

6

1

0

2

6

1

1

2

6

1

2

2

6

1

3

2

6

1

4

2

6

1

5

The CAN bus connection from ESX 0 to ESX 1 was lost within the process phase - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX The CAN bus connection from ESX 0 to ESX 1 was lost within the configuration phase - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX Error within the configuration phase: ESX 1 is a control system from another type of crane - The connection to ESX 1 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX Error within the configuration phase: ESX 1 has the wrong version of software - The connection to ESX 1 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX Error within the configuration phase: ESX 1 has a serial number, however the EEPROM data is not valid - The connection to ESX 1 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX Error within the configuration phase: ESX 1 has an incorrect serial number - The connection to ESX 1 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX Error within the configuration phase: The CAN bus connection from ESX 0 to ESX 1 was lost during the transition of ESX 1 to the STOP mode - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX

System Description GMK 4075 Error Codes

2

6

1

6

2

6

2

0

Index

Error

Device No.

Fig.

Group

Page 23

Error within the configuration phase: The configuration data from ESX 1 could not be fully received - The connection to ESX 1 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX The CAN bus connection from ESX 0 to ESX 1 was lost during the transition from the configuration phase to the process phase - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX

Description

No. Fig.

3

6

0

0

3

6

1

0

3

6

1

1

3

6

1

2

3

6

1

3

3

6

1

4

The CAN bus connection from ESX 0 to ESX 2 was lost within the process phase - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX The CAN bus connection from ESX 0 to ESX 2 was lost within the configuration phase - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX Error within the configuration phase: ESX 2 is a control system from another type of crane - The connection to ESX 2 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX Error within the configuration phase: ESX 2 has the wrong version of software - The connection to ESX 2 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX Error within the configuration phase: ESX 2 has a serial number, however the EEPROM data is not valid - The connection to ESX 2 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX Error within the configuration phase: ESX 2 has an incorrect serial number - The connection to ESX 2 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX

System Description GMK 4075 Error Codes

3

6

1

5

3

6

1

6

3

6

2

0

Index

Error

Device No.

Fig.

Group

Page 24

Error within the configuration phase: The CAN bus connection from ESX 0 to ESX 2 was lost during the transition of ESX 2 to the STOP mode - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX Error within the configuration phase: The configuration data from ESX 2 could not be fully received - The connection to ESX 2 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX The CAN bus connection from ESX 0 to ESX 2 was lost during the transition from the configuration phase to the process phase - The sensors and valves connected to this ESX are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this ESX

Description

No. Fig.

5

6

0

0

5

6

1

0

5

6

1

1

5

6

1

2

5

6

1

3

5

6

1

4

5

6

1

5

The CAN bus connection from ESX 3 to ESX 4 was lost within the process phase - The carrier can no longer be operated from the superstructure cab The CAN bus connection from ESX 3 to ESX 4 was lost within the configuration phase - The carrier can no longer be operated from the superstructure cab Error within the configuration phase: ESX 4 is a control system from another type of crane - The connection to ESX 0 is lost - The carrier can no longer be operated from the superstructure cab Error within the configuration phase: ESX 4 has the wrong version of software - The connection to ESX 0 is lost - The carrier can no longer be operated from the superstructure cab Error within the configuration phase: ESX 4 has a serial number, however the EEPROM data is not valid - The connection to ESX 0 is lost - The carrier can no longer be operated from the superstructure cab Error within the configuration phase: ESX 4 has an incorrect serial number - The connection to ESX 0 is lost - The carrier can no longer be operated from the superstructure cab Error within the configuration phase: The CAN bus connection from ESX 3 to ESX 4 was lost during the transition from ESX 4 to the STOP mode - The carrier can no longer be operated from the superstructure cab

System Description GMK 4075 Error Codes

5

6

1

6

5

6

2

0

Index

Error

Device No.

Fig.

Group

6

0

0

9

6

1

0

9

6

2

0

Index

Error

Device Fig.

Error within the configuration phase: The configuration data from ESX 4 could not be fully received. - The carrier can no longer be operated from the superstructure cab The CAN bus connection from ESX 3 to ESX 4 was lost during the transition from the configuration phase to the process phase - The carrier can no longer be operated from the superstructure cab

Description

No. Fig.

9

No.

Page 25

Group

The CAN bus connection from ESX 4 to IO 0 was lost within the process phase - The sensors and valves connected to this IO are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this IO The CAN bus connection from ESX 4 to IO 0 was lost within the configuration phase - The sensors and valves connected to this IO are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this IO The CAN bus connection from ESX 4 to IO 0 was lost during the transition from the configuration phase to the process phase - The sensors and valves connected to this IO are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this IO

Description

No. Fig.

10

6

0

0

10

6

1

0

10

6

2

0

The CAN bus connection from ESX 4 to IO 1 was lost within the process phase - The sensors and valves connected to this IO are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this IO The CAN bus connection from ESX 4 to IO 1 was lost within the configuration phase - The sensors and valves connected to this IO are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this IO The CAN bus connection from ESX 4 to IO 1 was lost during the transition from the configuration phase to the process phase - The sensors and valves connected to this IO are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this IO

System Description GMK 4075 Error Codes

Device No.

Fig.

Group

Index

Error

6

0

0

11

6

1

0

11

6

2

0

Index

Error

Device

12

12

12

Fig.

Description

No. Fig.

11

No.

Page 26

Group

The CAN bus connection from ESX 4 to IO 2 was lost within the process phase - The sensors and valves connected to this IO are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this IO The CAN bus connection from ESX 4 to IO 2 was lost within the configuration phase - The sensors and valves connected to this IO are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this IO The CAN bus connection from ESX 4 to IO 2 was lost during the transition from the configuration phase to the process phase - The sensors and valves connected to this IO are no longer available to the ECOS - Functional restrictions are imposed on the drive units, the sensors or valves of which are connected to this IO

Description

No. Fig. 6

6

6

0

1

2

0

0

0

The CAN bus connection from ESX 3 to IO 3 was lost within the process phase The CAN bus connection from ESX 3 to IO 3 was lost within the configuration phase The CAN bus connection from ESX 3 to IO 3 was lost during the transition from the configuration phase to the process phase

System Description GMK 4075 Error Codes

Device No. 19

Fig.

Group

Index

Error

Description

No. Fig. 6

0

0

20

6

0

0

22

6

0

0

23

6

0

0

24

Page 27

6

0

0

The CAN bus connection from ESX 3 and ESX 0 to the EKS was lost The CAN bus connection from ESX 1 to the cable length sensor was lost The CAN bus connection from ESX 4 to MMI 1 was lost The CAN bus connection from ESX 4 to MMI 2 was lost The CAN bus connection from ESX 4 to the inclination sensor was lost

System Description GMK 4075 Error Codes

3 Assignment of the ESX Pin

Designation

Pin

Designation

27

1st CAN bus, dominant higher, W+

38

Digital speed input 9

st

26

1 CAN bus, dominant lower, W-

16

Digital speed input 10

33

2nd CAN bus , dominant lower, W-

39

Digital speed input 11

53

2nd CAN bus, dominant higher, W+

17

Digital speed input 12

23

8.5 V output

40

Digital speed input 13

6

Analogue input 1

18

Digital speed input 14

29

Analogue input 2

41

Digital speed input 15

7

Analogue input 3

19

Digital speed input 16

30

Analogue input 4

46

Digital/PWM output 1 (4Awith current measurement)

8

Analogue input 5

47

Digital/PWM output 2 (4A with current measurement)

31

Analogue input 6

48

Digital/PWM output 3 (4A with current measurement)

9

Analogue input 7

49

Digital/PWM output 4 (4A with current measurement)

32

Analogue input 8

64

Digital/PWM output 5 (4A with current measurement)

42

Digital/PWM output 13, (4 A)

61

Digital/PWM output 6 (4 A)

20

Digital/PWM output 14, (4 A)

62

Digital/PWM output 7 (4 A)

43

Digital/PWM output 15, (4 A)

63

Digital/PWM output 8 (4 A)

21

Digital/PWM output 16, (4 A)

24

Digital/PWM output 9 (2.5 A)

44

Digital/PWM output 17, (4 A)

2

Digital/PWM output 10 (2.5 A)

22

Digital/PWM output 18, (4 A)

25

Digital/PWM output 11 (2.5 A)

45

NC

3

Digital/PWM output 12 (2.5 A)

11

NC

1

Earth, Analogue

50

NC

55

Earth Electrics, Digital

51

NC

65

Earth for Babyboard 1

52

NC

66

Earth for Babyboard 1

10

NC

67

NC

28

D+ input

68

NC

34

Digital speed input 1

4

Serial interface, RxD

12

Digital speed input 2

5

Serial interface, TxD

35

Digital speed input 3

56

Voltage supply 12 V (24 V), UB (Battery)

13

Digital speed input 4

57

Voltage supply 12 V (24 V), UB (Battery)

36

Digital speed input 5

58

Voltage supply 12 V (24 V), UB (Battery)

14

Digital speed input 6

59

Voltage supply 12 V (24 V), UB (Battery)

37

Digital speed input 7

60

Voltage supply 12 V (24 V), UB (Battery)

15

Digital speed input 8

54

Voltage supply 12 V (24 V), UE (Emergency)

Page 28

System Description GMK 4075 Error Codes

Page 29