Heli Error Codes Fault Overhaul Manual [PDF]

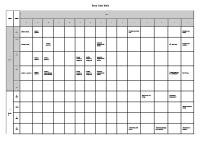

1. ALARM CHECK 1. Step on the acceleration after key .If forward and backward both not to move. Advice according to fo

181 3 257KB

Papiere empfehlen

![Heli Error Codes Fault Overhaul Manual [PDF]](https://vdoc.tips/img/200x200/heli-error-codes-fault-overhaul-manual.jpg)

- Author / Uploaded

- Петр

Datei wird geladen, bitte warten...

Zitiervorschau

1.

ALARM CHECK 1. Step on the acceleration after key .If forward and backward

both not to move. Advice according to following. Led no Flash .

Flash one.

Check chopper’ s EPROM port volt

Check chopper controlport voltage output whether or not.

Yes V.

Logic failure

No V.

Check-up fuse and key if failure. Wiring key to D1 if in gear

No V.

Logic failure.

Check acceleratio n pin unless has volt.

Yes

Keep up check chopper ’s output if it is ok.

No

Check conned line to the control and the acceleration.

Yes

If the control’s output is ok.

No

Check seat-switch hand-switch

Yes

If the control’s output is ok.

No

Check NO.15 break or not.

Yes volt Check chopper control port volt.

Inspect NO.15 wire unless has volt to forward and backward contact coil.

wire

or

is

2.Step on the acceleration after key on. If forward and backward are both not to moving. But LED is coruscated. Then observe the LED time and the code of instrument.

2、ALARM CODE COAD -006

PHENOMENON

LIGHT

FORKTRUCK IS WORK

HANDSET UNIT

None

None

TYPE H 0 、H 1 N D 、H 2 B 、 DUAL-SEM2

Symptom: Working is ok. Reason: a.

Turned

on

the

key,

CHOP PER

working is ok. b.

Inspect:

the

wire

chopper ’s

pin

of B B1 PCLRXD

(DUAL-S EM is C) and the instrument, and if connection is carve out a way or relax. c.

Instrument

is

wrong

and replacing. d.

Proof

the

control’s

parameter again.

CHOPPER

B2 NCLRXD

CONSOLE

B 3 P C LT X D

C O N N E C T O R B 4 N C LT X D

CODE

PHENOMENON

-007

LIGHT

STEP PED IS SLOWLY

1

HANDSET UNIT

TYPE

CHOPPER NO

H1DN 、H2B、

CONFIG

DUAL-SEM2 ZAPI.

SYMP TOM: Moving slowly REASON: a. Turn on the key and appear this code. For the setup of the logic is change. b.

Inspect:

input

information again.

the

right

CODE

PHENOMENON LOGIC

-008

LIGHT

SE LF-

DIAGNOSE

No working REASON : a. The test is moving and standby. If slowing the code and you must instead the logic. logic

is

WATCH DOG

TYPE H0 、H1DN 、H 2B

SYMP TOM:

b. Inspect:

1

HANDSET UNIT

wrong

replacing the chopper

and

CODE

PHENOMENON RUNNING IS OK

-010

SYM PTOM: Running is ok. REASON: a. Alarm happens on the area for the EPRO M running time. It does not effect the fork-truck moving. b. Inspect: after opening the key and then closing it immediately. This alarm is disappearing. But notice now the time is setup 0.

LIGHT 1

HANDSET UNIT

TYPE

EE PROM DATA

H0 、H1DN 、D

KO

UAL-SE M

CODE

PHENOMENON

LIGHT

NO WORKING

-011

1

SYMP TOM: No working. REASON: a. EPROM

memory

parameter

level is error and the fork-truck is not work. b. Inspect: after opening the key and

then

closing

digital-control

it.

If

appears

the this

alarm all the same. Then you should

instead

the

logic.

Contrarily indication the alarm is this

already time

disappearing. the

data

But of

memorizing is already change. So must set over again.

HANDSET UNIT

TYPE

EEPROM PAR .

H0 、H1DN 、H

KO

2B

CODE

PHENOMENON

LIGHT

NO WORKING

-012

1

SYMP TOM: No working REASON: a. The data model of memorizing the type of chopper is wrong. b. Inspect: If failure still happens after electro lock is turned off and then on please replace the logic

card.

disappears

If the

failure

code

setting

of

chopper should be set up again because

the

ariginal

sitting

have been replace by wrong data please refer to the handset unit.

HANDSET UNIT

TYPE

EEPROM CONF .

HO、H1DN、

KO

H2B

CODE

PHENOMENON NO WORKING

-013

LIGHT 1

HANDSET UNIT

TYPE

EEPROM KO

H1DN、DUA L-S EM2

SYMP TOM: NO RUNNING REASON: a. The area of memorizing data is wrong so that the fork-truck no work. b. If you close and open the key time after the alarm is all the same being. You must replace the logic unit. On the contrary you must set over again

CODE

PHENOMENON

-014

RUNNING OK

LIGHT 1

HANDSET UNIT EE POMM OFF LINE

SYMP TOM Running ok REASON: a. Fault in the nonvolatile memory that contains data relative to the area for the hour-meter, the alarm

stored

and

the

programming parameters. b. If the alarm persists when the key

is

switched

off

again, replace the logic.

and

on

TYPE H2B

CODE

PHENOMENON

LIGHT

NO WORKING

- 015

HANDSET UNIT

3

R

,

VMN

NOT

OK , L VMN NOT

-016

OK

SYMP TOM: NO RUNNING + B AT T

REASON: a. This test is performed at rest,

B AT T

with the main contactor close,

F1L

and also during operation.

F2L

b. At rest if VMN is lower than

FUSE

DUAL-SEM2 VMNL

battery voltage this Alarm is

R

generated Daring operation this

LEFT MOTOR

Alarm

RIGHT MOTOR

is

generated

if

VMN

doesn’t follow the duty cycle of

VMNR

R

the chopper possible causes. c. Incorrect motor connection.

F1R

d. Frame fault of motor to chassis.

F2R

e. Defect in the power unit please replace the chopper.

B AT T — B AT T

TYPE DUAL-SEM2

CODE

PHENOMENON

-

NO RUNNING

017

LIGHT

HANDSET UNIT

R V FIELD NOT DUAL-SEM2

3

OK , L V FIELD

,

NOT OK

-018 SYMP TOM: No working

+ B AT T

REASON: a. This is made at standby with

FUSE

B AT T F1L

the main contactor open. b. Inspect: In this condition the voltage on both the connections

F2L

DUAL-SEM2 VMNL

of field must be to around the

R

50 percent V BATT. This alarm

LEFT MOTOR

is

RIGHT MOTOR

generated.

If

the

field

voltage is different from this

VMNR

R

value. Possible causes: c. Frame fault on the motor to chassis.

F1R F2R

d. In correct connection of the field winding to the chopper. e. Failure of the chopper in the section relative to the field.

TYPE

B AT T — B AT T

CODE - 020

PHENOMENON

LIGHT

RUNNING NOT OK

3

,

-022

HANDSET UNIT

TYPE

FORW

VMN

H1DN

LOW , BACK

VMN

LOW SYM PTOM

NO WORKING

H1DN + B AT T

REASON: a. This

test

performed

at

rest. If VMN is lower than 1/3

battery

voltage

(in

gear

voltage

VMN

–B

is

lower

voltage)

80% this

generated.

and

battery alarm

motor

B AT T -SH

A1

DF

M A2 TA D1

TI D2

is

Possible VMN1

causes: b. The

FUSE

+SH

is

possible

wrong.

VMN2

c. If the control not output, and

please

chopper.

replace

the B AT T — B AT T

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-030

RUNNING NOT OK

3

VMN LOW

H2B

SYM PTOM NO WORKING

-B

REASON: a. The

test

is

-B TFR

carried

out

at

TA A 1 A 2 T I

M1

TFR TA A 1 A 2 T I

M1

standby and in running up to

+SH

+SH

80%

VMN

SH -SH

SH -SH

voltage is lower than 1/3 of the

VMN

VMN

of

battery

PW M.

voltage,

If

an

the

alarm

is

shown. b. Inspect: causes

for

finding

follow

the

out

the

diagnosis

CORRECT

ERROR

procedure here following.

2. Disconnecting the contactor wire always

c. At the key on, test1: disconnect

excited

from

board

connector

if

the

the motor cable connected to

contactor is no longer excited, replace

the battery and then verify if

the logic board.

the alarm still present. Result:

A3_ A running contactor is stuck on working

yes, fault description point: A1.

position, unlock the contactor, it could be

Result: no. Test2: a running

possible to replace the contactor.

contactor is locked in working

B1_wrong connections of the motor cables.

position, result: yes. Test3: the

The stator and the armature are crossed.

stuck contact coil is supplied?

B2_There is a current dispersion in the

Result: yes, fault description

motor between the stator winding and the

pointA2.

armature

Result:

no,

fault

one

otherwise,

there

are

some

description point A3. If test2

electric parts of these winging that makes a

result:

contact inside the motor.

no.

Fault

description

point B1, B2, B3 . d. Running

with

running

B3_Check that there are not metallic parts

contactors

positions.

on

inside the contactor board that cause a short

Fault

towards the negative in the points connected

description point: A1.

to _SH and +SH.

e. As soon as the accelerator pedal

B4_ If there is the bypass contactor check

is completely released for doing

that it is not stuck or it is too much slow in

a release braking. Test1: is it

opening.

present

the

bypass

weakening

contactor?

yes.

description

Fault

or

Result: point:

A1. f.

A1_ the most probably reason is that it is not stuck or it is too much slow in opening. A2_if

the

running

contactor

remains stuck, you can verify: 1, if the wire going from NTA to NT1 is casually in short with a metallic part connector to the

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-031

NO WORKING

8

VMN HIGH

H0 、H2B

SYM PTOM NO WORKING REASON: a. Test carried out in standby. If the VMN voltage is greater than 2/3

V.

BATT.

An

alarm

is

shown. b. Forward /backward contactor is stuck

on

working

position.

Inspect contactor ’s touch point is

connect

or

not.

And

the

winding’s line way is correct or error. c. There is a current dispersion in the motor between the stard or winding and the armature on otherwise,

there

are

some

electronic parts of these wining that makes contact inside the motor. Please repair the motor. d. Short circuit between +BATT and VMN, please check if there are any metallic parts causing short circuit in the contactor board. e. The

motor

winding

connect

error. f.

Logic braking

failure,

probably

diode

replace the power.

are

the

broken,

CODE

OHENOMENON

LIGHT

HANDSET UNIT

TYPE

-033

NO WORKING

3

NO FULL COND

H0 、H1DN 、H 2B

SYM PTOM No working 。 REASON: a. The test is carried out in full conduction. If in this condition, the VMN is found to be greater than 1/3 V.B ATT, the diagnostic circuit is faulty causing a safety risk and this

machine

hibitied.

If

the

replace the logic.

operation defect

is

in

persists,

CODE -037

PHENOMENON RUNNING NOT OK

LIGHT

HANDSET UNIT

TYPE

6

CONTACTOR

DUAL-SEM2

CLOSED SYM PTOM NO WORKING REASON: a. This check is made during the initial diagnosis. With the coil of the line contactor denergised the capacitors should not be changed unless there is divert resistor across the power poles. Possible causes. b. The contactor power poles are welded or slow to open. c. This alarm could be generated if the line contactor has been opened, but there is a problem with either the field circuit or a problem detected by the safety microprocessor.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-039

NO WORKING

9

BRAKE CON

H2B

CLOSED SYM PTOM RUNNING NOT OK. REASON: a. This test is carried out in the passage from running to initial

GPin

H2B

3

6

1

4

regenerative braking. b. If on running contactor closure, the VMN is more than 2/3 V. BATT,

an

alarm

is

issued.

Possible causes: c. The normally open contactor of the

braking

contact

is

stuck

unlock the contact and clean it. If

it

is

too

much

damaged

replace the contactor. d. The braking contactor remains excited for a defect in the logic board

or

because

the

NTFR

wire is in short towards the negative.

G7

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-040

NO WORKING

8

BRAKE CONT.

H2B

OPEN SYMP TOM

H2B CHOPPER

NO WORKING A

REASON: a.

Test

carried

passage

to

out

during

running.

the After

B

closes, verifying that the VMN goes from less than 1/3 to more than 2/3. if this does not occur, an alarm is shown. And then

C

D

inspect the fuse. b.

Test: at running

request the

TFR closes for 0.3sec? result: yes_A1; test: when there’s the running

request

is

there

a

voltage at pin BT FR for a time of 0.3sec? result: yes. Fault result description at point:B2.

E

C1 C2 C3 D1 D2

E1 E2 E3 E4 E5 38 15 E 6 旁路 再生 前进 后退 转向 E 7 TB TFR TA TI SP E8 41 31 27 23 60 E9 15 23 41 38 27 31 1 2 3 4 5 6

result: no. fault result:A4. test:

A1 — there is not a good contact on the NA

check with an ohmmeter of the

of TFR, clean the contact, if it too much

TFR coil is interrupted. Result:

damaged replace the contact.

yes. Fault result description at

A2 —missing

point :B1.

braking contact

the

positive

cable

on

the

A3 —supply doesn’t come up to the contact coil,

please

check

the

cabling

and

connection from the coil to the connector G4 and G6. B1 —replace

the

contactor

coil

or

the

complete contactor. B2 —contactor mechanically locked, unlock it and replace it.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-041

NO WORKING

9

DIR. CON.

H2B

CLOSED SYM PTOM

H2B CHOPPER

NO WORKING. A

REASON: a. Test the VMN voltage carried out

during

the

passage

to

B

standby or breaking. Check that the running contactor opens by comparing the consistent status. b. Running

contactor

stuck

or

C

D

slow to open. c. Logic failure. E

C1 C2 C3 D1 D2

E1 E2 E3 E4 E5 38 15 E 6 旁路 再生 前进 后退 转向 E 7 TB TFR TA TI SP E8 41 31 27 23 60 E9 15 23 41 38 27 31 1 2 3 4 5 6

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-042

RUNNING NOT OK

8

DIR CONT OPEN

H2B

S Y M P TO M : NO WORKING REASON: a.

Te s t c a r r i e d o u t r u n n i n g r e q u e s t : r u n n i n g c o n s i s t e n t . P o s s i b l e ca u s e s :

b.

P h e n o m e n o n : c o n d i t i o n u n d e r w h ic h

fault is detected: Only at forward

A 1 — T h e r e i s n o t a g o o d c o n t a c t e i t h e r o n TA

running

see

(=forward contactor) ,NA( Normally open) or on

f o r w a r d c o n t a c t o r ( TA ) c l o s i n g f o r

TI (= backward contactor), (normally closed). Due

0. 3 s e c . T h e n o p e n i n g ? R e s u l t : y e s -

t o d u s t , d i r t o r a n y p a r t i c le s , w h i c h p r e v e n t a

A 1. F a u l t d e s c r i p t i o n a t p o i n t : A 1 ,

valid

test:

c o m p r e s s e d a i r ; i f n e c e s s a r y r e m o ve d i r t a p p l y i n g

request.

when

Te s t :

you

r e q ue s t i n g

forward

c o n t a c t.

Clean

contact

by

means

of

r u n n i n g y o u w i l l f i n d a n y p a g e at

a soft abrasive movement.

coil

A 2 — F o r w a r d c o n t a c t o r ( TA ) i s s u p p l i e d w i t h a

contacts

for

0.3sec?

Result:

Ye s - A 2 ; N o - A 3 . O n l y a t b a c k w a r d

correct

running

causes:

request.

Te s t :

you

see

v o l ta g e

but

it

d o e s n ’t

c l o se .

Possible

backward contactor (T1) closing for

A 3 — S u p p l y d o n ’t c o m e u p t o TA, p l e a s e c h e c k

0. 3 s e c , t h e n o pe n i n g ? R e s u l t : Ye s -

c a b l i n g a n d c o n n e c t i n g f r o m T I c o i l t o co n n e c t o r s

A 4, t e s t : w h e n r e q u e s t i n g b a c k w a r d

P T a n d NTA .

r u n n i n g y o u f i n d a n y v o l t a g e at c o i l

A 4 — T h e r e i s n o t a g o o d co n t a c t o r e i t h e r o n T I

c o n t a c t s f o r 0. 3 s e c ? R e s u l t : Ye s -

( = b a c k w a r d c o n t a c t o r ) N A ( n o r ma l l y o p e n ) o r o n

B 1, N o - B 2. A t b o t h r u n n i n g r e q u e s t .

TA ( = f o r w a r d c o n t ac t o r ) N C ( n o r m a l l y c l o s e d )

Te s t : y o u s e e f o r w a r d o r b ac k w a r d

d u e t o d u s t , d i r t o r a n y p a r t ic l e s w h i c h p r e v e n t a

c o n t a c t o r (TA o r T I ) c l o s i n g f o r

valid

0. 3 s e c . t h e n o pe n i n g . Te s t 2 : w h e n

c o m p r e s s e d ai r.

requesting forward running you find

B 1 — B a c k w a r d co n t a c t o r ( T I ) i s s u p p l i e d w i t h a

a n y v o l t a g e a t TA c o i l ’s c o n t a c t s o r

c o r r e c t v o l ta g e b u t i t d o e s n ’t c l o se .

at

B2—Backward

backward

contactor

c o i l ’s

c o n t ac t

clean

contacts

contactor

(TI)

by

is

means

supplied

of

not

c o n t a c t ( B T 1 ) f o r 0. 3 se c ? R e s u l t :

v o l t a g e . I n s p e c t G 1 ( N O . 1 5 ) a n d G 2 ( N O. 2 3 )

Ye s - B 4 ; N o - B 5 .

B 3 — T h e m o s t p r o b a b l y r ea s o n i s t h a t t h e n o r m a l l y c l o s e d c o n ta c t o f t h e b r a k i n g c o n t a c t o r d o e s n ’t m a k e a g o o d co n t a c t t o w a r d s t h e d o e s n ’t l e a n completely

for

a

mechanical

de f e c t

of

the

c o n t a c t o r. B 4 — B a c k w a r d a n d f o r w a r d c o n t a c t o r a re s u p p l i e d w i t h a c o r r e c t v o l t a g e b u t t h e y d o n ’t c l o s e ; s e e p o i n t B 1. B 5 — S u p p l y d o n ’t c o m e u p TA a n d T I. P l e a s e c h e c k G 1 ( N O . 1 5 ) an d G 5 ( N O . 2 7 ) o f TA . T h e n c h e c k G 1 ( N O. 1 5 ) an d ( N O. 2 3 ) o f T I.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-049

RUNNING NOT OK

5

I=0 EVER

H0 、H1DN 、H 2B

SYM PTOM

400A

+B

NO WORKING.

TFR

REASON: a. Test

TA A 1 A 2 T I

carried

out

in

running

check

that

the

current

during

running

is

greater

than

M1

+SH

a

SH -SH

VMN D2

minimum

value. If not, an alarm is signaled is

and

shut

the

down.

machine

D1

-B

H2B

Possible

FUSE + S H + B AT T

causes: b.

The faulty

current replace

sensor the

-SH

is

DF A1

M

power

A2

unit. c. Wrong

connections

of

TA D1

the

TI D2

VMN1

motor cables to the power

VMN2

bars SH- and SH+. d. Wrong of the motor so that

- B AT T

a

larger

than

value

possible

there

is

a

resistance

H1DN

causes: not

good

+ S H + B AT T 电流检测 -SH

connect to brush. A1

M

A2 TA D1 VMN1

- B AT T

TI D2

CODE

PHENOMENON

LIGHT

-050

NO WORKING

5

-051

HANDSET UNIT RIGHT

I= 0

E V E R , L E F T I= 0 EVER

SYM PTOM NO WORKING. REASON: a. This

check

is

made

during

travel. If the current is not higher than a present minimum value, this alarm is generated and

the

machine

disabled.

Possible causes: b. See STBY I HIGH. Check the motor

armature

connections)

(brush

TYPE DUAL-SEM2

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-053

NO MOVING

5

STBY I HIGH

H1DN 、H2 B ZAPI

SYM PTOM NO WORKING. REASON: a. Test

carried

standby.

Check

out

in

that

the

current is nil. If this is not

nil,

an

signaled

alarm

and

is

inhibits

machine operation. b. Pin

SH-

load

or

connects not

another

moving

the

motor. c. Current logic

broken

failure.

replace the

sensor

the

defect

logic

and

First and

persists

if

then

replace the power unit.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-054

NO MOVING

5

RGT STBY I

DUAL-SEM2

HIGH,LEFT

-055

STBY I HIGH SYM PTOM NO WORKING. REASON: a. This test is made during the initial diagnosis and at standby. The

test

current

is

verifies zero.

that This

the alarm

disables the machine. Possible causes: b. Defective current sensor. c. Logic failure. F irst replace the logic,

if

the

fault

replace the power unit.

remains

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-061

ST EPP ED IS SLOWLY

7

HIGH

DUAL-SEM2

TEMP ERATURE SYM PTOM ST EPP ED IS SLOWLY. REASON: a. If

the

temperature

of

the

chopper rises than 77C, this alarm is generated. The chopper current is reduced in proportion to the increase in temperature. At

92C

the

chopper

totally

stops. If the temperature of the chopper is less than –10C, this alarm is also generated and the current is reduced by 80%, if this alarm is displayed when the chopper is temperature is the same as ambient or better than zero degrees. b. Check the connection of the temperature sensor. c. The temperature sensor may be

defective. d. The logic may be defective.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-062

ST EPP ED IS SLOWLY

7

THERMAL

H0 、H1DN、H

PROTEC TION

2B

SYM PTOM MOVING IS SLOWLY. REASON: a.

An

indication

controller’s has

that

temperature

exceeded

76C(H0)

the

80C

(H2B)

75C(H1DN),

and

appeared the alarm. b.

The maximum is gradually reduced, reaching 0 at a temperature

of

85C(H2B,

H1DN), 86C(H0). c.

If the alarm occurs while cold,

the

most

probably

reason is the failure of the

thermic

circuit on

on

the

replace

diagnosis

the logic

on

of

power

or

board, the

two

parts

or

replace

the

complete controller. d.

If the alarm often occurs after

short

machine

time

is

probably

the

working,

it

is

due

to

inadequate

heat

check

fixing

nuts

and

the

the

tightening

sink,

correct installation.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-066

ST EPP ED IS SLOWLY

32

BATTERY LOW

H 0 、H 1 N D 、H 2 B 、 DUAL-SEM2

SYM PTOM RUNNING TO SLO W. REASON a. The battery charge is low. The alarm

is

“BATT ERY been

signaled CHECK”

selected

from

only

if

the

option

has

the

serial

console (default). When this alarm occurs, the maximum current is reduced to 50%.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-070

NO WORKING

5

R FIELD I

DUAL-SEM2

-071

LOW,L FIE LD

-072

I LOW,R

-073

FIE LD HIGH ,L FIE LD I HIGH SYM PTOM NO WORKING. REASON

a. Problem detected with the field winding

current.

Possible

causes: b. Failure

of

the

field

current

sensor. c. Field cables not connected or incorrectly connected. d. Open circuit field winding. e. Failure of the field power unit.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-075

RUNNING NOT OK

6

CONTACTOR

DUAL-SEM2

DRIVER SYMP TOM: NO WORKING. REASON: a. The

alarms

are

generated

if

there is a problem with the main

contactor.

Possible

causes: b. The coil of the contactor is

either

Open

short

circuit.

circuit

or

not

coil

drive

connected. c. The

contactor

is short circuit. d. Defect

in

the

wiring

to

the

contact,

or

logic

failure.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-075

RUNNING NOT OK

6

CONTACTOR

H1DN

DRIVER SYMP TOM: NO WORKING. REASON: a. The

test

is

made

in

both

running and standby. The test verifies

that

the

contactor

voltage is high of running and standby unit

low.

inspect

running

to

Using E3,

handiest E8.

And

GND, standby to

VCC. If not, possible causes: b. There is a short circuit between E3 and E8. c. Due to over loading or short circuit

so

that

the

driving

enginery is damaged.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-076

RUNNING NOT OK

6

COIL SHORTED

H2B

SYM PTOM RUNNING NOT OK. REASON: a. Contactor load

or

driver short

output

over

circuit

with 38

BATT+. Possible causes: b. Contactor

coil

shorted

or

passed the current than 6A. c. The

line

of

contact

15

旁路 再生 前进 后退 转向

pin

TB

H2B

TFR

41 31

TA

15 23 41 38 27 31

is

shorted with BATT+ . The alarm

TI

27 23 60

1 2 3 4 5 6

SP

phenomenon has happened the over

loading,

but

not

the

chopper wrong.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-076

NO WORKING

6

COIL SHORTED

DUAL-SEM2

SYMP TOM: RUNNING NOT OK

10A 1 KEY

REASON: a. Contact coil shorted. Possible causes.

8 A 9

b. Contact coil wrong. c. Connection the coil wrong. d. Connection the contact wrong or logic.

15

DUAL-SEM2

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-078

RUNNING NOT OK

4

VACC NOT OK

H1DN 、H2B、 DUAL-SEM2

SYM PTOM NO WORKING. 1

REASON: a. Test the output voltage of acceleration standby.

under

The

generated

alarm

voltage 2V

differs

from

the

(+12V) 12

is

13

the

14

output

15

if

acceleration

A

more

than

acquired

DUAL-SEM2

minimum during the PROGRAM VACC; possible causes: b. The

track

of

C1(输入 0-10V)

the

C

C2(负极)

potentiometer is not wired

H2B 、H1DN

correctly. c. The

C3(+12V)

potentiometer

itself

is defective.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-079

RUNNING NOT OK

2

INCORRECT

H 0 、H 1 N D 、H 2 B 、

START

DUAL-SEM2

SYMP TOM: NO WORKING. REASON: a. The

alarm

incorrect

generated starting

by

an

sequence.

Possible causes: b. The

ENABLE

micros-witch

sequence has welded or failed. c. Error in the starting sequence

from the operator. d. Error in the wiring and replace the logic.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-080

NO WORKING

ALWAYS

FORW+BACK

H 0 、H 1 N D 、H 2 B 、

LIGHT SYMP TOM: NO WORKING. REASON: a. This check is made continually. The alarm is generated when forward and reverse directions are

requested

simultaneously.

Possible causes: b. Incorrect wiring. c. Welding

or

failure

direction switch.

of

a

DUAL-SEM2

d. Incorrect

operation

from

the

operator.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-084

NO WORKING

4

STEER SENSOR

DUAL-SEM2

KO SYM PTOM NO WORKING. 1

REASON. a. The control microprocessor verifies that the steering signal

is

in

the

range

(+10V)

B

6 7 8

stored. Possible causes: 12

b. Bad end of stroke stored. c. Error

in

the

potentiometer.

steering

DUAL-SEM2

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-086

NO WORKING

4

PEDAL WIRE

DUAL-SEM2

KO SYMP TOM: NO WORKING. 1

REASON:

A

a.

This

alarm

is

generated

if

正极(+12V) 12 负极

potentiometer or wiring fault is

13

detected (NPOT or PPOT are open

14

circuit), then appearing the alarm.

15

输入端

DUAL-SEM2

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-086

NO WORKING

6

PEDAL WIRE

H0

KO SYMP TOM NO WORKING. REASON: a. On

NPOT

pin

(A12),

potentiometer connected,

no

detected,

thus

where

negative

is

voltage

is

indicating

that potentiometer is not supplied due 1 of 2 supply wires cut off. b. Wire toward PPOT (A14) is disconnected. c. Wire toward NPOT (A12) is disconnected. d. Potentiometer

resistance

is cut off. e. Potentiometer

presents

a

resistance greater than 47 K-ohm.

+B A5

12V FEEDER

A14 82Ω

A13 A12 -B

H0

(2k)

CODE

PENOMENON

LIGHT

HANDSET UNIT

TYPE

-090

NO WORKING

8

DRIVER 1 KO

H0

SYMP TOM: +B

RUNNING NOT OK. REASON: a.

A5

12V FEEDER

A14 82Ω

Indicates that NT1 (A11)

A13

connector voltage is not

A12 -B

with

the

A9

value;

the

A10 A6

consistent expected machine

is

inhibited

A2 A8

possible causes: b.

Either

wire

toward

A1

NT1

connector is disconnected or

backward

A3

contactor

coil is break off. c.

DRIVER1

A4

DRIVER2 -B B1

A11

Inside chopper mosfet is shorted; replace chopper.

Handset unit

H0

B8

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-091

NO WORKING

8

DRIVER 2 KO

H0

SYMP TOM: +B

NO WORKING. REASON: a.

Indicates

that

connector

A14

NT2

voltage

82Ω

(A4) is

A13

no

A12 -B

consistent with the expected

A9

value;

A10 A6

the

machine

is

inhibited. Possible causes: b.

A5

12V FEEDER

Either

wire

toward

A2 A8

NT2

A1

connector is disconnected or forward contactor coil is break

A3

off. c.

Inside

chopper

mosfet

is

DRIVER1

A4

DRIVER2 -B B1

A11

shorted; replace chopper.

HANDSET UNIT

H0

B8

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-092

NO WORKING

8

DRIVER 1 SIC

H0

KO SYMP TOM: +B

NO WORKING. REASON:

A14 82Ω

a. In indicates a current on driver

A5

12V FEEDER

of

A13

contactor

A12 -B

connected

to

NT1

A9 A10 A6

(A11);

the machine is inhibited.

A2

Possible causes: b.

A8

Short circuit between positive

A1

and the wire toward NT1. c.

Contactor coil shorted or coil

A3

current up take greater than 5A.

DRIVER1

A4

DRIVER2 -B B1

A11

HANDSET UNIT

H0

B8

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-093

NO WORKING

8

DRIVER 2 SIC

H0

KO SYM PTOM NO WORKING.

+B A5

12V FEEDER

REASON:

A14 82Ω

a. It indicates a current over load

A13

on driver of contactor to NT2

A12 -B

(A4); the machine is inhibited,

A9

possible causes:

A10 A6

b. Short circuit between positive

A2 A8

and the wire toward NT2.

A1

c. Contactor coil shorted or coil current up take greater than 5A.

A3

DRIVER1

A4

DRIVER2 -B B1

A11

HANDSET UNIT

H0

B8

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-094

NO WORKING

1

MICRO CHECK

DUAL-SEM2

KO SYMP TOM: NO WORKING REASON: a. During the initialize diagnose, the

main

microprocessor

inspected and fix on the safety microprocessor. If it is error, then appear the alarm, possible causes: b. Safety

microprocessor

was

failure. c. Safety microprocessor was in danger,

and

contactor

not

working. d. Logic was fault, advice replace the logic card.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-096

NO WORKING

8

BRAKE DRIVER

DUAL-SEM2

KO SYM PTOM: NO WORKING. REASON: a. It is appear when testing to the electronic

brake.

Possible

causes: b. Driving machine short- circuit. c. Driving machine is wrong. d. The

electronic

brake

coil’s

discharge-loop is wrong.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-096

RUNNING NOT OK

9

INVER SION

H0

SYM PTOM: +B

RUNNING NOT OK.

A5

12V FEEDER

REASON:

A14 82Ω

a. It indicates that quick inversion

A13

key is being pressed at key-

A12 -B

A9 A10 A6

start- up possible error. b. Quick inversion micro switch

A2

stuck.

A8

c. Operator action error.

A1

d. Error either in quick inversion micro

switch

programming;

cabling

or

this

in

alarm

occurs, for example, whenever, following scheme, it’s cabled to use IRZ input, while chopper is programmed viceversa.

for See

par

A3

IRE

or

4.5

and

DRIVER1

A4

DRIVER2 -B B1

A11

HANDSET UNIT B8

H0

drawings chapter 6.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-097

NO WORKING

9

POSITION

H0

HANDLE

SYMP TOM: NO WORKING. REASON: a.

It

indicates

that

tiller

was

lowered into running position prior alarm

to

key-start-up.

is

not

This

activated

SAF ETY

SWI TCH

programmed

FREE .

if is

Possible

causes: b.

Operator correct

error

relating

sequence

and

to

tiller

micro switch stuck.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-097

NO WORKING

2

HANDBRAKE

DUAL-SEM2

SYMPTOM RUNNING NOT OK. REASON: a. The alarm phenomenon handle

brake

is

not

opened

before

closed the key. b. Possible causes: the order of operation

is

wrong

handbrake

or switch

conglutination.

CODE

PHENOMENON

LIGHT

HANDSET UNIT

TYPE

-09 8

NO WORKING

NONE

NONE

DUAL-SEM2

SYM PTOM RUNNING NOT OK. REASON: a. Instrument has a E PROM itself to save the hour data. If the chopper has been instead, the hour data will distract to new chopper. So the fork truck’s

maintenance data may not lose for replacing the chopper. And you must operate to following. b. With

the

key

switch

open,

connect the ZAPI console (mini NOT connected). Close the key switch

.

set

the

function

“LOAD HM FROM MDI” to ON. this can be found in the HARDWARE

SETTING

MEU

(ZAPI protected menu). In some versions, this function may be called “AUX FUNCTION 1” to ON. c. Open

the

key

switch.

Disconnected the ZAPI console. Connect the MDI and then close the key switch. d. Notice: the alarm “-98”, after one minute this alarm will be disappear. And then the fork truck is OK.

The Alarm Check Handbook Of ZAPI Control

EDITOR: Zhang Yi

Qin Li Electronics Co., Ltd