ECOS Error Codes - 5220 [PDF]

Go To > ECOS System Description GMK 5220 Error Codes Valid as of ECOS Version 01.00.00 Olaf Berthold TK4, 21.11.2005

45 0 1MB

Papiere empfehlen

![ECOS Error Codes - 5220 [PDF]](https://vdoc.tips/img/200x200/ecos-error-codes-5220.jpg)

- Author / Uploaded

- Benjamín Sancho Contreras

Datei wird geladen, bitte warten...

Zitiervorschau

Go To >

ECOS System Description GMK 5220

Error Codes

Valid as of ECOS Version 01.00.00

Olaf Berthold TK4, 21.11.2005

Go To >

Table of Contents 1

GENERAL DESCRIPTION .......................................................................................... 1 1.1 1.2 1.3

2

LIST OF THE DEVICES .................................................................................................... 1 LIST OF THE GROUPS ..................................................................................................... 2 LIST OF THE ERRORS...................................................................................................... 2

ERROR TABLES............................................................................................................ 3 2.1 ESX............................................................................................................................... 3 2.1.1 Digital Inputs of ESX 0..3 ........................................................................................ 3 2.1.2 Outputs of ESX 0..3.................................................................................................. 4 2.1.3 Analogue Inputs of ESX 0..3 .................................................................................... 5 2.2 IO BOARDS.................................................................................................................... 5 2.2.1 Analogue Inputs of IO Boards 0..3 .......................................................................... 5 2.2.2 Digital Inputs and Outputs of IO Boards 0..3.......................................................... 6 2.3 CONTROL LEVER ........................................................................................................... 7 2.4 RADIO CONTROL ERROR ............................................................................................... 8 2.5 PLATFORM ERROR ......................................................................................................... 8 2.6 ECOS ............................................................................................................................ 9 2.6.1 Change-over Contact Group ................................................................................... 9 2.6.2 Carrier ..................................................................................................................... 9 2.6.3 System Monitoring ................................................................................................... 9 2.6.4 Main Hoist ............................................................................................................. 10 2.6.5 Auxiliary Hoist....................................................................................................... 11 2.6.6 Derricking Gear..................................................................................................... 11 2.6.7 Telescoping Gear ................................................................................................... 11 2.6.8 Slewing Gear.......................................................................................................... 12 2.6.9 Pinning System....................................................................................................... 12 2.6.9.1Explanations regarding Error Message 25.16.3.n...................................................................... 14 2.6.9.2Display Information................................................................................................................... 15

2.6.10 3

Can Bus ............................................................................................................. 16

ASSIGNMENT OF THE ESX ..................................................................................... 21

System Description GMK 5220 Error Codes

Go To >

Page 1

1 General Description The ECOS offers the possibility of electrically monitoring the sensors, actuators and equipment connected to the system. The error message produced by ECOS consists of four figure displays, which can be any value between 0 and 255. A new error message is indicated by a flashing warning triangle and can be displayed via the function key [?]. The number code is constructed as follows: XXX – XXX – XXX – XXX Error number Index Group number Device number The allocation of device and group is the same for all error messages. Index and error number can be used as an extended error message for certain devices. In this case, no figure appears in the display for the index and/or no figure appears for the error number.

1.1 List of the Devices Device No. Device

Fig.

Device No.

Device

1

ESX 0

18

Right control lever

2

ESX 1

19

RCI

3

ESX 2

20

Precision length sensor

4

ESX 3

21

Display

9

IO 0

22

MMI 1

10

IO 1

23

MMI 2

11

IO 2

24

Inclination sensor

12

IO 3

25

ECOS

13

IO 4

26

Radio control

17

Left control lever

27

AMG module

28

Working platform

Fig.

System Description GMK 5220 Error Codes

Go To >

Page 2

1.2 List of the Groups Group No.

Group

Fig.

1

Digital input

2 3

Output

6

Group No.

ESX Units IO Boards

Group

17

Carrier

Analogue input IO Boards

18

System monitoring

ESX Units IO Boards

20

Main hoist

CAN bus

21

Auxiliary hoist

12

Change-over contact

22

Derricking gear

14

Axis X

23

Telescoping gear

15

Axis Y

24

Slewing gear

16

Pinning system

ESX Units

1.3 List of the Errors Error No.

Fig.

Error

Sources of errors

2

Cable break

3

Short circuit to Vcc

4

Short circuit to ground

7 8 9 10 11

Digital inputs Digital outputs Digital inputs Digital outputs Digital inputs Digital outputs Analogue inputs

Below minimum threshold value Above maximum Analogue inputs threshold value ADC value does not suit Digital inputs digital level Digital inputs Undefined status System error (development phase) Initialising software

13

Function call software

14

Logic

15 16

Not used PWM signal missing

System error (development phase) Control lever Rocker switch --Digital inputs

Fig.

System Description GMK 5220 Error Codes

Go To >

2 Error Tables 2.1 ESX 2.1.1 Digital Inputs of ESX 0..3 1

2

Device Number 3

4

1

IN3504

S2301P

IN0101T

NC

2

A1101/7

S2302P

S4211

S4108M

3

A1201/7

NC

S1102

IN3602

4

IN3503

S0105P

S3702/24/34

S4155M

5

A1101/3

S2111P

S3702/44

NC

6

A1101/4

S2112P

IN0104

S0291P

7

A1201/3

S2209N

IN0107

S4101M

8

A1201/4

S2210N

IN0110

S4104M

9

S1101P

NC

J3502-16

S4103M

10

S1102P

NC

IN3506

S4120P

11

S1201P

NC

S3530

S4106P

12

S1202P

NC

S2112

S4154M

13

S2101P

NC

S2404

S4102M

14

S2102P

NC

S2304

IN3604

15

IN3505

NC

S3710

S4105M

16

A1201_14

NC

J3501-16

S4109M

Index

Page 3

System Description GMK 5220 Error Codes

Go To >

2.1.2 Outputs of ESX 0..3 1

2

Device Number 3

1

OUT1100

OUT2300

B3401

NC

2

OUT1200

Y2305

J3501-13

NC

3

OUT2100

Y2105

J3502-13

Y4106

4

OUT2110

Y2115

OUT3401

NC

5

Y3403

Y2306

B3702

NC

6

Y3501

Y2304

H2404

OUT3601

7

Y1104

Y2307

H1102

Y4103

8

Y1105

Y2104

H1202

Y4709

9

Y1204

K2112

S1202

Y4101

10

Y1205

M0101

H0107

NC

11

K3510

Y2134

NC

M0202

12

K3511

Y2133

H3501

NC

13

K1101

K2301

H2304

Y4102

14

K1102

K2302

H2102

K4109

15

K1201

K2101

H2112

Y4104

16

K1202

K2102

S2102

Y4105

17

K0106

K2111

H3502

K0207

18

U0 VCC perm

U1 VCC perm

U2 VCC perm

U3 VCC perm

4

Index

Page 4

System Description GMK 5220 Error Codes

Go To >

Page 5

2.1.3 Analogue Inputs of ESX 0..3 Device Number 1

2

3

4

1

IN3503a

IN2302P

S0106

S0240T

2

IN2401

IN2103P

S0107

S0209Q

3

IN3709

IN2201

OUT3507

NC

4

OUT0101

S0143T

S3401

NC

5

OUT0102

IN2205

IN2301

NC

6

IN3501P

IN2206

IN4201

NC

ESX identity ESX identity

ESX identity ESX identity

ESX identity ESX identity

ESX identity ESX identity

Index

7 8

2.2 IO Boards 2.2.1 Analogue Inputs of IO Boards 0..3 Device Number 9

10

11

12

13

1

S4706

S4405P

S4407P

NC

NC

2

NC

S4406P

S4408P

NC

NC

3

NC

S4320P

S4324P

NC

NC

4

NC

S4321P

S4325P

NC

NC

5

NC

S4322P

NC

NC

NC

6

NC

S4323P

NC

NC

NC

7

NC

NC

NC

NC

NC

8

NC

NC

NC

NC

NC

Index

System Description GMK 5220 Error Codes

Page 6

Go To >

2.2.2 Digital Inputs and Outputs of IO Boards 0..3

I

O

9

Device number 11

10

12

13

Index O

1

K3610

2

K3611

3

S3399N

4

K0205

5

S4301

6

NC

7

S0202_1

8

S0206P

9

S0202_2

10

S0202_3

11

S4702_3

12

S4702_4

13

S0202_4

14

S0201_9

15

S0201_10

16

NC

17

K0210

18

NC

Y4406

19

NC

Y4421

20

NC

Y4461

21

K3602

22

NC

Y4405

23

NC

Y4411

24

B3304

O I O I

S4301N Y4301A S4302N Y4301B S4303N Y4302A

I I I I I I I I I

S4304N Y4302B

O

O

O I O I O I O

NC Y4303A S0210P Y4303B

Y4304A

O I O

O

Y4401

Y4451

S4306N

S4307N

O O O O O O O O

I

I

I

O

O

O

Y4403 Y4407 Y4431 Y4471

S2311N S2312N

O

NC

Y4481

Y2311B Y2312B

NC

Y4441

Y2311A Y2312A

NC

Y4408

S0110P S0106P

NC

Y4404

S0109P S2303P

NC

Y4305B

A2320/5 S0102P

NC S4308N

S2323 A2320/7

NC

Y4306B O

I

NC

Y4306A

NC

Y4402

S4305N

Y4305A

NC

Y4304B O

I

O O O O O O O O

I I I I I I I I O O O O I I

S3709N S3710N

NC NC NC S3706N S3708N S2110N S2111N S2112N S2113N S2114N S2115N S2116N

NC

S2117N

Y3402 Y2401 Y2402 Y2201 Y2202 NC NC

O O O O O O O O

I

NC

NC

Y3401

I

Y2130 Y2131 NC NC NC NC NC NC

I I I I I I I I I I O O

System Description GMK 5220 Error Codes

Go To >

Page 7

2.3 Control Lever Device No.

Fig.

Group No.

Index

Fig.

Error No.

Description

Fig.

17

6

0

0

Malfunction of the CAN bus connection to control lever.

17

18

0

1

Error in the electronics. Both axes failed, replace control lever.

17

12

0

14

Both directional contacts switched Rocker switch not functioning

17

14

0

1

Redundant system failed. Control lever can continue to be used. If the error occurs at each restart, replace control lever.

17

14

0

2

Axis failed. If the error occurs at each restart, replace control lever.

17

15

0

1

Redundant system failed. Control lever can continue to be used. If the error occurs at each restart, replace control lever.

17

15

0

2

Axis failed. If the error occurs at each restart, replace control lever.

18

6

0

0

Malfunction of the CAN bus connection to control lever.

18

18

0

1

Error in the electronics. Both axes failed, control lever must be replaced.

18

12

0

14

Both directional contacts switched Rocker switch not functioning

18

14

0

1

Redundant system failed. Control lever can continue to be used. If the error occurs at each restart, replace control lever.

18

14

0

2

Axis failed. If the error occurs at each restart, replace control lever.

18

15

0

1

Redundant system failed. Control lever can continue to be used. If the error occurs at each restart, replace control lever.

18

15

0

2

Axis failed. If the error occurs at each restart, replace control lever.

System Description GMK 5220 Error Codes

Go To >

Page 8

2.4 Radio Control Error Device

Group

No. Fig. No.

Index

Error Description

Fig. Malfunction of the CAN bus connection to the radio control. Alife counter incorrect

26

6

0

0

26

6

0

1

Malfunction of the CAN bus connection to the radio control. CRC incorrect

26

6

0

2

Malfunction of the CAN bus connection to the radio control. Time Out

26

6

0

3

Malfunction of the CAN bus connection to the radio control. Message 1 missing

26

6

0

4

Malfunction of the CAN bus connection to the radio control. Message 2 missing

26

18

0

0

Transmitter error. Control lever 1 defective

26

18

0

1

Transmitter error. Control lever 2 defective

26

18

0

2

Transmitter error. Control lever 3 defective

2.5 Platform Error Device

Group

No. Fig. No.

28

18

Index

Error Description

Fig.

0

0

Platform error

System Description GMK 5220 Error Codes

Go To >

Page 9

2.6 ECOS 2.6.1 Change-over Contact Group Device No.

Group

Fig.

No.

Index

Error

Fig.

No.

Description

Fig. Both directional contacts switched (Tilt cab)

25

12

0

14

25

12

1

14

Both directional contacts switched (Increase speed)

2.6.2 Carrier Device No.

Group

Index

Error

Description

Fig.

25

17

0

0

25

17

0

1

25

17

0

4

25

17

0

5

25

17

0

6

25

17

0

15

Steering cylinder with length measuring system axle 2 value too low Steering cylinder with length measuring system axle 2 value too high Steering cylinder with length measuring system axle 1 value too low Steering cylinder with length measuring system axle 1 value too high Both switches steering to left and to right are activated simultaneously Illogical status of the switches in the separate steering pot; poss. mixed up

2.6.3 System Monitoring Valid for devices No. 1 to 4 or to

No. 9 to 12 to

Device Group

Index

Error

1..4

18

0

1

1..4

18

0

2

1..4

18

0

4

1..4

18

0

6

1..4

18

0

7

1..4

18

0

8

Description Error in the control system’s start phase • The earth connection to the housing of the relevant ESX is not OK • The housing’s earthing should be checked. Error in the control system’s start phase • One of the outputs of the relevant ESX has a connection to the supply voltage. Error in the control system’s start phase • The initiating current of the output VCC perm. is greater than 3 amperes. • A component at the Vcc perm. connection is causing a short circuit Operating error • The total of all of the VCC perm. output current was greater than 10 amperes. • A component at the Vcc perm. connection is causing a short circuit Operating error • The total of all the output currents was greater than 28 amperes. Operating error • The 8.5V output voltage is outside the tolerance. • A component at the 8.5V connection is causing a short circuit, or the control system is defective.

System Description GMK 5220 Error Codes 1..4

18

0

9

1..4

18

0

10

9..12

18

1

0

9..12

18

1

1

9..12

18

1

2

Go To >

Page 10

Operating error • Slave has detected a failure of the CAN masters. • The CAN bus connection should be checked. Operating error • The control system’s output drivers are not supplied with voltage. • Check fuses and supply voltage. Error during access to the EEProm • Board is to be replaced, if error message occurs with increased frequency No voltage supply via plug X9.1 of IO board • Check wiring to IO board and also fuse on the IO board No voltage supply via plug X9.2 of IO board • Check wiring to IO board and also fuse on the IO board

2.6.4 Main Hoist Device

Group

Index

Error Description

No. Fig.

No.

Fig.

25

20

2

0

25

20

2

1

25

20

2

2

25

20

2

3

25

20

2

4

Control pressure (LS) detected for positive and negative direction of movement In the positive direction of movement control pressure (LS) was detected for negative direction of movement In the negative direction of movement control pressure (LS) was detected for positive direction of movement In the STOP condition control pressure (LS) was detected for positive direction of movement In the STOP condition control pressure (LS) was detected for negative direction of movement

System Description GMK 5220 Error Codes

Go To >

Page 11

2.6.5 Auxiliary Hoist Device

Group

Index

Error Description

No. Fig.

No.

Fig.

25

21

2

0

25

21

2

1

25

21

2

2

25

21

2

3

25

21

2

4

Control pressure (LS) detected for positive and negative direction of movement In the positive direction of movement control pressure (LS) was detected for negative direction of movement In the negative direction of movement control pressure (LS) was detected for positive direction of movement In the STOP condition control pressure (LS) was detected for positive direction of movement In the STOP condition control pressure (LS) was detected for negative direction of movement

2.6.6 Derricking Gear Device

Group

No. Fig. No.

Index

Error Description

Fig.

25

22

2

0

25

22

2

1

25

22

2

2

25

22

2

3

25

22

2

4

Control pressure (LS) detected for positive and negative direction of movement In the positive direction of movement control pressure (LS) was detected for negative direction of movement In the negative direction of movement control pressure (LS) was detected for positive direction of movement In the STOP condition control pressure (LS) was detected for positive direction of movement In the STOP condition control pressure (LS) was detected for negative direction of movement

2.6.7 Telescoping Gear Device

Group

Index

Error Description

No. Fig.

No.

Fig.

25

23

2

0

25

23

2

1

25

23

2

2

25

23

2

3

25

23

2

4

Control pressure (LS) detected for positive and negative direction of movement In the positive direction of movement control pressure (LS) was detected for negative direction of movement In the negative direction of movement control pressure (LS) was detected for positive direction of movement In the STOP condition control pressure (LS) was detected for positive direction of movement In the STOP condition control pressure (LS) was detected for negative direction of movement

System Description GMK 5220 Error Codes

Go To >

Page 12

2.6.8 Slewing Gear Device

Group

No. Fig. No.

Index

Error Description

Fig.

25

24

2

0

25

24

2

1

25

24

2

2

25

24

2

3

25

24

2

4

Control pressure (LS) detected for positive and negative direction of movement In the positive direction of movement control pressure (LS) was detected for negative direction of movement In the negative direction of movement control pressure (LS) was detected for positive direction of movement In the STOP condition control pressure (LS) was detected for positive direction of movement In the STOP condition control pressure (LS) was detected for negative direction of movement

2.6.9 Pinning System Device

Group

Index

Error

Description

No. Fig.

25

16

0

0

25

16

1

4

25

16

1

5

25

16

2

1

25

16

2

2

25

16

2

3

Error of the EKS4 length sensor for the telescoping cylinder length - The redundant length control (comparison of ECOS length with EKS4 length) is no longer operating, resulting in losses in the system safety of the telescoping system Error in comparing the ECOS length with the EKS4 length - The difference in the two lengths has exceeded the tolerance threshold (set by service software), i.e. one of the two length sensors is emitting an invalid value - Semi- and fully automatic operation are no longer functioning; the pinning system can only be operated in emergency operation - During emergency operation the current length of the ECOS length sensor and the EKS4 length sensor are displayed; a decision has to be made as to which length information is correct Error in controlling the telescoping cylinder movement - It was established that the current direction of movement of the telescoping cylinder contradicts the telescoping system’s operating status (e.g. retracting direction of movement and extending operating status) - Semi- and fully automatic operation are no longer functioning; the pinning system can only be operated in emergency operation Error in controlling the telescope status - The telescope status is inconclusive in itself (e.g. more than one telescope section unlocked) - All the functions of the telescoping system are blocked; a valid telescope status must first be input or a change made to emergency operation Error in controlling the telescope status - The position of the telescoping cylinder in connection with the telescope status contradicts the pinning system’s operating status (is only evaluated in TLSL operating status) - All the functions of the telescoping system are blocked; a valid telescope status must first be input or a change made to emergency operation Error in controlling the telescope status - The current telescope status contradicts the pinning system’s current operating status (e.g. TLSU operating status, however according to telescope status no telescope section is unlocked) - All the functions of the telescoping system are blocked; a valid telescope status must first be input or a change made to emergency operation

System Description GMK 5220 Error Codes

25

16

2

4

25

16

2

5

25

16

3

n

25

16

4

0

25

16

5

0

25

16

5

1

25

16

6

n

Go To >

Page 13

Error in controlling the telescope status - The proximity switches’ signals for detecting the position of the telescoping cylinder (S2116N, S2117N, S3709N, S3710N) contradict the pinning system’s current operating status (e.g. TLSU operating status, however none of the proximity switches has switched) - All the functions of the telescoping system are blocked; a valid telescope status must first be input or a change made to emergency operation Error in controlling the telescope status - The proximity switches’ signals for detecting the position of the telescoping cylinder (S2116N, S2117N, S3709N, S3710N) contradict the telescope status and the position of the telescoping cylinder (this error is only evaluated in TUSL operating status; proximity switches have switched but the telescoping cylinder is not within a foot section) - All the functions of the telescoping system are blocked; a valid telescope status must first be input or a change made to emergency operation Error in detecting the locking status - The evaluation of the proximity switches’ signals for detecting the locking status (S2110N – S2115N) produces an invalid status - Semi- and fully automatic operation are no longer functioning; the pinning system can only be operated in emergency operation - The error number 'n' indicates which proximity switches (S2110N S2115N) were switched at the time the error occurred - See explanations regarding this in Chapter ??? Error in the unlocking mechanism - The wrong pins were released during an unlocking request (e.g. request for the telescoping cylinder to be unlocked, but the telescope section was unlocked) - Presumed error: valve Y2130 for switching over unlocking between telescoping cylinder and telescope section is sticking. - Semi- and fully automatic operation are no longer functioning; the pinning system can only be operated in emergency operation Error of proximity switches S3709N and S3710N - Both proximity switches S2116N and S2117N have switched, but neither of the proximity switches S3709N nor S3710N have switched. - Possible mechanical cause: the telescoping cylinder moved to the right so that the proximity switches on the left-hand side of the telescoping cylinder have lost contact to the trigger plates. - There might be function restrictions of the telescoping system. The recognition of the foot sections might fail. It may be that the telescoping cylinder cannot be locked to a telescope section any more. In this case, the telescoping system can only be operated in emergency operation. Error of proximity switches S2116N and S2117N - Both proximity switches S3709N and S3710N have switched, but neither of the proximity switches S2116N nor S2117N have switched. - Possible mechanical cause: the telescoping cylinder moved to the left so that the proximity switches on the right-hand side of the cylinder have lost contact to the trigger plates. - There might be function restrictions of the telescoping system. The recognition of the foot sections might fail. It may be that the telescoping cylinder cannot be locked to a telescope section any more. In this case, the telescoping system can only be operated in emergency operation. Error of the proximity switch S2116N, S2117N, S3709N or S3710N - The error code number 'n' determines the respective proximity switch to which the error message relates: n = 0 → S2116N n = 1 → S2117N n = 2 → S3709N n = 3 → S3710N - The proximity switch remains switched all the time although the telescoping cylinder is not within a foot section of a telescope section

System Description GMK 5220 Error Codes

Go To >

Page 14

2.6.9.1 Explanations regarding Error Message 25.16.3.n Error message 25.16.3.n (device = ECOS, group = pinning system) denotes an error during the detection of the current locking status. The evaluation of the signals of proximity switches S2110N to S2115N produces an invalid condition. The error number of this error message (designated here by 'n') reflects the switched condition of these proximity switches at the time the error occurred. Determining the switched conditions of the proximity switches from the error number 'n': The proximity switches have various weightings, which are as follows: S2114N (Tele cyl. lock. left)

→

Weighting

=

1

S2115N (Tele cyl. lock right)

→

Weighting

=

2

S2112N (Tele cyl. unlock. left)

→

Weighting

=

4

S2113N (Tele cyl. unlock right)

→

Weighting

=

8

S2111N (Boom section locked)

→

Weighting

=

16

S2110N (Boom section unlocked) →

Weighting

=

32

In order to now determine the proximity switches’ switched conditions from the error number 'n', the error number 'n' is split up into the sum of the proximity switches’ weightings. If the sum includes a weighting, this means that the proximity switch belonging to this weighting was switched at the time the error occurred. All proximity switches, the weightings of which are not included in the sum, were not switched. Example: Error message = 25.16.3.33 → Error number n = 33 → 33 = 32 + 1, the error number n = 33 includes weightings 32 and 1 → at the time the error occurred only proximity switches S2110N and S2114N were switched

0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1

The IO signals of ESX 1 and the IO board to the telescoping cylinder not enabled No control status available, or telescoping system deactivated Precision length sensor is not transmitting any data RCI has switched off the voltage supply of the IO signals

NC NC IO board on the telescoping cylinder failed ESX1 control system failed

Error in mechanics of unlocking system Error in status of telescoping system Error in telescoping direction Error in length comparison of ECOS RCI

Error of precision length sensor Error of valve Error of high/low proximity switch Error of unlocked/locked proximity switch

System Description GMK 5220 Error Codes Go To > Page 15

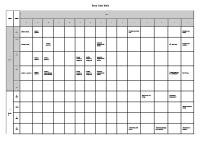

2.6.9.2 Display Information

System Description GMK 5220 Error Codes

Go To >

Page 16

2.6.10 Can Bus Device No. Fig.

Group No.

Index

Error Description

Fig.

1

6

0

0

1

6

1

0

1

6

1

1

1

6

1

2

1

6

1

3

1

6

1

4

1

6

1

5

1

6

1

6

1

6

2

0

The CAN bus connection from ESX 2 to ESX 0 was lost within the process phase - The superstructure can no longer be operated from the cab The CAN bus connection from ESX 2 to ESX 0 was lost within the configuration phase - The superstructure can no longer be operated from the cab Error within the configuration phase: ESX 0 is a control system from another type of crane - The connection to ESX 0 is lost - The superstructure can no longer be operated from the cab Error within the configuration phase: ESX 0 has the wrong version of software - The connection to ESX 0 is lost - The superstructure can no longer be operated from the cab Error within the configuration phase: ESX 0 has a serial number, however the EEPROM data is not valid - The connection to ESX 0 is lost - The superstructure can no longer be operated from the cab Error within the configuration phase: ESX 0 has an incorrect serial number - The connection to ESX 0 is lost - The superstructure can no longer be operated from the cab Error within the configuration phase: The CAN bus connection from ESX 3 to ESX 0 was lost during the transition of ESX 0 to the STOP mode - The superstructure can no longer be operated from the cab Error within the configuration phase: The configuration data from ESX 0 could not be fully received. - The superstructure can no longer be operated from the cab The CAN bus connection from ESX 2 to ESX 0 was lost during the transition from the configuration phase to the process phase - The superstructure can no longer be operated from the cab

System Description GMK 5220 Error Codes

Device

Group

No. Fig. No.

Index

Go To >

Page 17

Error Description

Fig.

2

6

0

0

2

6

1

0

2

6

1

1

2

6

1

2

2

6

1

3

2

6

1

4

2

6

1

5

2

6

1

6

2

6

2

0

The CAN bus connection from ESX 0 to ESX 1 was lost within the process phase - The sensors and valves connected to this ESX are no longer available to the ECOS The CAN bus connection from ESX 0 to ESX 1 was lost within the configuration phase - The sensors and valves connected to this ESX are no longer available to the ECOS Error within the configuration phase: ESX 1 is a control system from another type of crane - The connection to ESX 1 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS Error within the configuration phase: ESX 1 has the wrong version of software - The connection to ESX 1 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS Error within the configuration phase: ESX 1 has a serial number, however the EEPROM data is not valid - The connection to ESX 1 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS Error within the configuration phase: ESX 1 has an incorrect serial number - The connection to ESX 1 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS Error within the configuration phase: The CAN bus connection from ESX 0 to ESX 1 was lost during the transition of ESX 1 to the STOP mode - The sensors and valves connected to this ESX are no longer available to the ECOS Error within the configuration phase: The configuration data from ESX 1 could not be fully received. - The connection to ESX 1 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS The CAN bus connection from ESX 0 to ESX 1 was lost during the transition from the configuration phase to the process phase - The sensors and valves connected to this ESX are no longer available to the ECOS

System Description GMK 5220 Error Codes

Device

Group

No. Fig. No.

Index

Go To >

Page 18

Error Description

Fig.

3

6

0

0

3

6

1

0

3

6

1

1

3

6

1

2

3

6

1

3

3

6

1

4

3

6

1

5

3

6

1

6

3

6

2

0

The CAN bus connection from ESX 0 to ESX 2 was lost within the process phase - The sensors and valves connected to this ESX are no longer available to the ECOS The CAN bus connection from ESX 0 to ESX 2 was lost within the configuration phase - The sensors and valves connected to this ESX are no longer available to the ECOS Error within the configuration phase: ESX 2 is a control system from another type of crane - The connection to ESX 2 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS Error within the configuration phase: ESX 2 has the wrong version of software - The connection to ESX 2 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS Error within the configuration phase: ESX 2 has a serial number, however the EEPROM data is not valid - The connection to ESX 2 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS Error within the configuration phase: ESX 2 has an incorrect serial number - The connection to ESX 2 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS Error within the configuration phase: The CAN bus connection from ESX 0 to ESX 2 was lost during the transition of ESX 2 to the STOP mode - The sensors and valves connected to this ESX are no longer available to the ECOS Error within the configuration phase: The configuration data from ESX 2 could not be fully received. - The connection to ESX 2 is lost - The sensors and valves connected to this ESX are no longer available to the ECOS The CAN bus connection from ESX 0 to ESX 2 was lost during the transition from the configuration phase to the process phase - The sensors and valves connected to this ESX are no longer available to the ECOS

System Description GMK 5220 Error Codes

Device

Group

No. Fig. No.

Index

Go To >

Page 19

Error Description

Fig.

4

6

0

0

4

6

1

0

4

6

1

1

4

6

1

2

4

6

1

3

4

6

1

4

4

6

1

5

4

6

1

6

4

6

2

0

The CAN bus connection from ESX 2 to ESX 3 was lost within the process phase - The carrier can no longer be operated from the superstructure cab The CAN bus connection from ESX 2 to ESX 3 was lost within the configuration phase - The carrier can no longer be operated from the superstructure cab Error within the configuration phase: ESX 3 is a control system from another type of crane - The connection to ESX 3 is lost - The carrier can no longer be operated from the superstructure cab Error within the configuration phase: ESX 3 has the wrong version of software - The connection to ESX 2 is lost - The carrier can no longer be operated from the superstructure cab Error within the configuration phase: ESX 3 has a serial number, however the EEPROM data is not valid - The connection to ESX 2 is lost - The carrier can no longer be operated from the superstructure cab Error within the configuration phase: ESX 3 has an incorrect serial number - The connection to ESX 2 is lost - The carrier can no longer be operated from the superstructure cab Error within the configuration phase: The CAN bus connection from ESX 2 to ESX 3 was lost during the transition of ESX 3 to the STOP mode - The carrier can no longer be operated from the superstructure cab Error within the configuration phase: The configuration data from ESX 3 could not be fully received. - The carrier can no longer be operated from the superstructure cab The CAN bus connection from ESX 2 to ESX 3 was lost during the transition from the configuration phase to the process phase - The carrier can no longer be operated from the superstructure cab

System Description GMK 5220 Error Codes

Device

Group

No. Fig. No.

9 10 11 9 10 11 9 10 11

Device

Error Description

0

6

1

6

2

Group

Index

0

0

0

The CAN bus connection from ESX 3 to the IO board was lost within the configuration phase - The sensors and valves connected to this IO board are no longer available to the ECOS The CAN bus connection from ESX 3 to the IO board was lost during the transition from the configuration phase to the process phase - The sensors and valves connected to this IO board are no longer available to the ECOS

Fig.

6

0

0

12 13

6

1

0

12 13

6

2

0

Group

No. Fig. No.

The CAN bus connection from ESX 3 to the IO board was lost within the process phase - The sensors and valves connected to this IO board are no longer available to the ECOS

Error Description

12 13

Device

Page 20

Fig.

6

No. Fig. No.

Index

Go To >

Index

The CAN bus connection from ESX 0 to the IO board was lost within the process phase - The sensors and valves connected to this IO board are no longer available to the ECOS The CAN bus connection from ESX 0 to the IO board was lost within the configuration phase - The sensors and valves connected to this IO board are no longer available to the ECOS The CAN bus connection from ESX 0 to the IO board was lost during the transition from the configuration phase to the process phase - The sensors and valves connected to this IO board are no longer available to the ECOS

Error Description

Fig.

17

6

0

0

18

6

0

0

19

6

0

0

20

6

0

0

22

6

0

0

23

6

0

0

24

6

0

0

26

6

0

0

28

6

0

0

The CAN bus connection from ESX 2 to the left control lever was lost The CAN bus connection from ESX 2 to the right control lever was lost The CAN bus connection from ESX 2 and ESX 0 to the EKS was lost The CAN bus connection from ESX 1 to the precision length sensor was lost The CAN bus connection from ESX 3 to MMI 1 was lost The CAN bus connection from ESX 3 to MMI 2 was lost The CAN bus connection from ESX 3 to the inclination sensor was lost The CAN bus connection from ESX 2 to the radio control was lost The CAN bus connection from ESX 2 to the platform was lost

System Description GMK 5220 Error Codes

Go To >

3 Assignment of the ESX Pin

Designation

Pin

Designation

27

1st CAN bus, dominant higher, W+

38

Digital speed input 9

st

26

1 CAN bus, dominant lower, W-

16

Digital speed input 10

33

2nd CAN bus, dominant lower, W-

39

Digital speed input 11

53

2nd CAN bus, dominant higher, W+

17

Digital speed input 12

23

8.5 V output

40

Digital speed input 13

6

Analogue input 1

18

Digital speed input 14

29

Analogue input 2

41

Digital speed input 15

7

Analogue input 3

19

Digital speed input 16

30

Analogue input 4

46

Digital/PWM output 1, (4 A with current measurement)

8

Analogue input 5

47

Digital/PWM output 2, (4 A with current measurement)

31

Analogue input 6

48

Digital/PWM output 3, (4 A with current measurement)

9

Analogue input 7

49

Digital/PWM output 4, (4 A with current measurement)

32

Analogue input 8

64

Digital/PWM output 5, (4 A with current measurement)

42

Digital/PWM output 13, (4 A)

61

Digital/PWM output 6, (4 A)

20

Digital/PWM output 14, (4 A)

62

Digital/PWM output 7, (4 A)

43

Digital/PWM output 15, (4 A)

63

Digital/PWM output 8, (4 A)

21

Digital/PWM output 16, (4 A)

24

Digital/PWM output 9, (2.5 A)

44

Digital/PWM output 17, (4 A)

2

Digital/PWM output 10, (2.5 A)

22

Digital/PWM output 18, (4 A)

25

Digital/PWM output 11, (2.5 A)

45

NC

3

Digital/PWM output 12, (2.5 A)

11

NC

1

Ground, analogue

50

NC

55

Ground electrics, digital

51

NC

65

Ground for Babyboard 1

52

NC

66

Ground for Babyboard 1

10

NC

67

NC

28

D+ input

68

NC

34

Digital speed input 1

4

Serial interface, RxD

12

Digital speed input 2

5

Serial interface, TxD

35

Digital speed input 3

56

Voltage supply 12 V (24 V), UB

13

Digital speed input 4

57

Voltage supply 12 V (24 V), UB

36

Digital speed input 5

58

Voltage supply 12 V (24 V), UB

14

Digital speed input 6

59

Voltage supply 12 V (24 V), UB

37

Digital speed input 7

60

Voltage supply 12 V (24 V), UB

15

Digital speed input 8

54

Voltage supply 12 V (24 V), UE

Page 21

System Description GMK 5220 Error Codes

Go To >

Page 22