Capabilty Output [PDF]

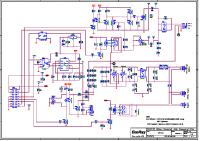

EQUIPMENT RENTAL RATES & CAPABILITIES, ACEL RATES January 2003 Ed. Table 1: RENTAL RATES & CAPABILITIES DESCRIPTION WOR

31 0 167KB

Papiere empfehlen

![Capabilty Output [PDF]](https://vdoc.tips/img/200x200/capabilty-output.jpg)

- Author / Uploaded

- Vanessa Condino

Datei wird geladen, bitte warten...

Zitiervorschau

EQUIPMENT RENTAL RATES & CAPABILITIES, ACEL RATES January 2003 Ed. Table 1: RENTAL RATES & CAPABILITIES DESCRIPTION

WORKING HOURS PER DAY=8 HRS. OPERATED PER HOUR

COMPUTED RENTAL RAT RATES PER DAY Asphaltic concrete Plant Php77,184.00 Asphalt Batching (Php 4824/mo. X Rated Cap. In Cu.M./Hr. = (4826/30 X 8 hrs X 60.0 Tons) = PhP 77,184.00 Portable Concrete Batching Plant Php16,576.00 30 Min/Batch (Php 6216/mo. X Rated Cap. In Cu.m. ={(6,216/30) X [(8 X 60) / 30] X 5.0 Cu.M. } = Php 16,576 per Day Rock Crusher Portable Parker Php !,556.55 Php12,452.40 Crushing Aggregates Bulldozer Komatsu D65A-8 Php2,090.00 Php16,720.00 Quarrying Bulldozer with Ripper + 35% Php2,808.00 Php22,464.00 Quarrying Backhoe Crawler MS180 Php1,748.00 Php13,984.00 Excavation Backhoe Crawler with Breaker + 35% Php2,359.80 Php18,878.00 Excavation Backhoe Crawler PC200-3 Php1,814.00 Php14,512.00 Excavation Loader Crawler Komatsu D-60S-7/DD Php1,418.00 Php11,344.00 Loading Loader Whell TCM/ Clark 75B Php1,255.00 Php10,040 Loading Road Grader MG500 Php1,101.00 Php8,808.00 Spreading Roller Bomag BW210DH Php1,398.00 Php11,184.00 Compacting Crane Crawler Type Php2,041.00 Php16,328.00 Lifting / Pile Driving Crane Truck Mounted Php2,095.00 Php16,760.00 Lifting / Pile Driving Crane Hydraulic Php2,452.00 Php19,616.00 Lifting / Pile Driving Hammer Diesel MH25 Php1,018.00 Php8,144.00 Pile Driving Hammer diesel MH35 Php1,284 Php10,272 Pile Driving Hammer Vibratory Php565.00 Php4,520 Pile Driving Transit Mixer 8-10 CU DYS Php1,486.00 Php11,888.00 Concrete Transport Concrete Mixer (1Bagger) Php156.00 Php1,248.00 Concrete Mixing Concrete Paver Roller Screed Php3,152.00 Php25,216.00 Concrete Paving Concrete Vibrator Gasoline Php78.13 Php625.04 Concrete Vibration Concrete Saw Gasoline Self Propelled Php332.03 Php2,656.24 Concrete Cuttung Plate Compactor (Vibratory) Php150.67 Php1,205.36 Compacting Air Compressor 161-185 CFM Php422.00 Php3,376.00 Power Generation Jack Hammer/ P. Breaker Php322.00 Php2,576.00 Breaking Bar Shear/ Cutter Php368.30 Php2,946.40 Bar Cutting Bar Bender Php418.53 Php3,348.24 Bar Bending Water Pump Diesel Php119.90 Php959.20 Water Pumping Wekding Machine Electric Driven/ DC output Php355.00 Php2,840.00 Weilding / Cutting Oxy-Acetylene/Cutting outfit Php64.00 Php512.00 Cutting Chainsaw w/out blade Php561.25 Php4,490.00 Cutting Generator Set Php126.42 Php1,011.36 Power Generation Dumpt truck (12-15 cu.Yds) Php1,127.00 Php9,016.00 Hauling / Transporting Water Truck ( 5000-6000 Gals) Php1,794.00 Php14,352.00 Water Supply Trailer 60 Ton PhP4.25/HR./Km Php9,562.50 Php76,500.00 Transporting ( PhP 4.25 X Wt. (Min.=15T) X No. of KM. + 50% Surcharge, Return trip Example (100KM) = (4.25 X 15 X 100) X 1.5 = PhP 16,576 per Day Cargot Truck ( 9-10 Tons) Php918.00 Php7,344.00 Hauling / Transporting

CAPABILITIES 60 Tons

TONS

Per Day

5.00 Cu.M.

Cu.M.

Per Batch

100 50 50 0.8 0.8 0.8 1.8 1.53 50 11 46-50 46-50 46-50 7500 10500 9.17 6.12-7.65 10-Jun

TONS Cu.M. Cu.M. Cu.M. Cu.M. Cu.M. Cu.M. Cu.M. Cu.M. TONS TONS TONS TONS Kg.-M. Kg.-M.

Per Hour Per Hour Per Hour Capacity Capacity Capacity Capacity Capacity Per Hour Capacity Capacity Capacity Capacity Rated Energy Rated Energy

Cu.M. Cu.M.

Capacity Per Hour

50 mm Max 6 3/4

Depth

Capacity

161-185

CPM

Capacity

Max 32mm Max 32mm 900 500

G40 G40 LPM APMS

Capacity Capacity Capacity Capacity

64-125 9.17-11.46 5000-6000 15

KVA Cu.M. Gals. TONS

51-100 HP Capacity Capacity Capacity

9-10

TONS

Capacity

EQUIPMENT CAPABILITIES Average Capabilities

Type of Equipment 1. Bulldozer (108)

2. Road Grader 3. Payloader 4. Crane Shovel 5. Sheep Foot Roller 6. 3- Wheel Road Roller 7. Tractor Drawn Roller 8. Tandem Roller 9. 9 1/2 T Dump Truck

10. 2 1/2 T Dump Truck

11. Buggy 12. Wheel Borrow 13. Water Tuck 14. Conrete Mixer 15. Rock Crusher 16. Conrete Virator 17. Concrete Floor Finisher 18. Percussioned Drilling

(a) Clearing 500 sq.m./hr. (b) Stripping 200 sq.m./hr. © Excavation: 1. Common soil 45 cu.m./hr 2. Slightly Hard Materials 25 cu.m./hr. (d) Quarrying: 107 Common Materials 50 cu.m./hr. 108 Aggregate 40 cu.m./hr. Boulders 15 cu.m./hr. 200 Needs Screening (e) Pushing 3 cu.m./hr. (a) Subgrading 300 sq.m./hr. (b) Spreading 50 cu.m./hr. (a) Loading 30 cu.m./hr. (a) Loading 35 cu.m./hr. (a) Satic rolling ( 12 passes- 15 cm 15 cu.m./hr. (b) Vibratory Rolling ( 4 passes- 1135 cu.m./hr. (a) Static Rolling ( 6 passes- 20 cm 24 cu.m./hr. (a) Vibratory Rolling (6 passes- 20 24 cu.m./hr. (a) Static Rolling ( 6 passes- 20 cm 24 cu.m./hr. (b) Vibratory Rolling (6 passes- 60 72 cu.m./hr. (a) Hauling Common Borrow Bas3.5 cum./hr. (b) Hauling Selected Borrow Bas5.0 cu.m./hr. © Hauling Concrete Batch Class 2 Batch/trip (a) Hauling Common Borrow Bas2.5 cu.m./trip (b) Hauling Selected Borrow Bas4.0 cu.m./trip © Hauling Concrete Batch Class 1 Batch/trip (a) Hauling Concrete Mix 0.17 cu.m./trip (a) Hauling Aggregates 0.17 cu.m./trip (b) Hauling Concrete Mix 0.05 cu.m./trip (a) Watering 1,000 sq.m./trip (a) Mixing Concrete 9 cu.m./hr. (a) Crushing Mixed Sand & Grav 30 cu.m./hr. (a) Vibrating Concrete Mix 40 cu.m./hr. (a) Finishing Concrete Floor 140 cu.m./hr. (a) Drilling Hard Rock 0.23 m./hr. (b) Drilling Loose Rock 0.30 m./hr. © Drilling Limestone 0.38 m./hr. (e) Drilling Loose Clay 0.70 m./hr.

TASK RATES FOR LABOR - BASED PROJECTS I. For Item 100 - Clearing & Grubbing Activity 1) Bush Clearing Bush Type a) light bush b) medium bush c) dense bush 2) Tree and Stump Removal 3) Grubbing Vegetation Type a) Dense vegetation in firm soil covering the whole area b) Spatse vegetation in loose soil II. For Item 105 - Excavation for Roadway & Drainage Activity 1) Excavation Soil Type a) Loose, rot sticky soil c) Very hard soil, hard soil mixed with Stones 2) Loading Type of Soil a) Loose b) Firm c) Hard

Productivity Sq.m./man-day 200 100 50 One (1) man-day per cm. of trunk diameter @ base of tree Sq.m./man-day

80 250

Productivity Cu.m./man-day ( Throwing distance in m. ) 0-4 m. 4-6 m. 5.0-6.0 4.5-5.5 3.5-4.5 3.4-4.0 2.0-3.0 1.8-2.5 Cu.m./man-day

6-8 m. 3.5-4.5 2.5-3.5 1.7-2.5

4.50-5.50 2.50-4.00 1.50-2.50

Excavation combined with loading of soil can be effectively carried out by laborers up to a loading height of about 1.00 m. e.g. into wheel borrow or head baskets. Above that height, it is preferable to have a separate group of loaders whose output must be matched with that of the excavators.

Soil Type a) Loose b) Loose c) Loose

Necessary output for the Loading Activity Loading Height Productivity cu.m./man-day 0-1 m. 12-15 1-2 m. 7-10 Over 2 m. 4-5

III. For Item 106- Excavation for Structures Activity 1) Excavation

IV. For Item 110- Foundation Fill Activity 1) Backfilling & Tamping

Productivitty Depending on the type of soil, they use similar data as those used for Excavation in Item 105

Productivity 3 cu.m./man-day

V. For Item 108- Aggregate Sub-base Course Activitty Productivity 1) Quarrying ( Excavation & Gravel) 0.50-2.00 cu.m./man-day 2) Loading 7.00-10.00 cu.m./man-day 3) Spreading 8.00-12.00 cu.m./man-day 4) Compacting 8.00-12.00 cu.m./man-day 5) Hauling activity should be considered in this Item, hence, hauling distance has an important beating on the cost of the gravelling operation, the maximum acceptable hauling distance has to be considered from case to case. VI. For Item 200- Aggregate Base Course Activity 1) Quarrying 2) Loading 3) Spreading 4) Compacting 5) Hauling- please refer activity no.5 of item 108 6) Scrapping VII. For Item 413 - Reinforced Concrete Pipe Culvert Activity 1) Crushing of stone for aggregate 2) Casting of culvert rings 3) Laying of standard culvert (24 in. dia.) of 0.60 m., dia., length 6.00 m. including excavation, culvert bad and backfill 4) Building of headwalls with masonry blocks

Productivity 0.50-2.00 cu.m./man-day 7.00-10.00 cu.m./man-day 8.00-12.00 cu.m./man-day 8.00-12.00 cu.m./man-day 3.00-5.00

Productivity 0.20 cu.m./man-day 2 man- day/ring

10 man-day/2 headwalls

If the length of a culvert exceeds 6 meters, the number of man-days has to be increased accordingly. Culvert laying - this task consist of the excavation of the trench preparing the bed, laying of culvert, backfilling and compaction. Number of man-days required varies with the volume of the excavation and the soil type.

FACTORS TO BE MULTIPLIED TO DETERMINE THE REQUIRED QUANTITY OF EACH MATERIAL CONCRETE CLASS 'A' CONCRETE ( 3,000 psi) CEMENT - 9.08 bags/cu.m. of concrete + 3-5% wastage SAND - 0.58 cu.m./cu.m. of concrete + 8-10% wastage GRAVEL - 0.77 cu.m./cu.m. of cocrete + 8-10% wastage CLASS 'B' CONCRETE ( 2,500 psi) CEMENT - 8.38 bags/cu.m. of concrete + 3-5% wastage SAND - 0.45 cu.m./cu.m. of concrete + 8-10 wastage GRAVEL - 0.82 cu.m./cu.m. of concrete + 8-10 wastage CLASS 'C' CONCRETE ( 3,500 psi) CEMENT - 9.77 bags/ cu.m. of concrete + 3-5% wastage SAND - 0.53 cu.m./cu.m. of concrete + 8-10% wastage GRAVEL - 0.70 cu.m./cu.m. of concrete + 8-10% wastage CLASS 'D' CONCRETE ( 4,000 psi) CEMENT - 11.17 bags/ cu.m. of concrete + 3-5% wastage SAND - 0.44 cu.m./cu.m. of concrete + 8-10% wastage GRAVEL - 0.68 cu.m/cu.m. of concrete + 8-10% wastage FOR BRIDGE ESTIMATE NUMBER for Falsework - 60 bd.ft./cu.m. of concrete NAILS - 2 kilos/cu.m. of concrete THE WIRES - 1.1 kilos/cu.m. of concrete Painting Structural Steel - 3 gals./ton AVERAGE FUEL CONSUMPTION PER DAY FUEL Crane, 140 liters ( diesel ) Diesel Hammer, 20 liters ( diesel ) Bulldozer, 200 liters ( diesel ) Payloader, 100 liters ( diesel ) Grader, 120 liters ( diesel ) Roller, 60 liters ( diesel ) Dump Truck, 60 liters ( diesel ) Mixer ( 1-bag ), 40 liters gasoline Vibrator 15 liters (gasoline ) Water Pump 15 liters ( gasoline ) One Bagger Mixer - 100 bags/day

ENGINE OIL 4 liters 3 liters 3 liters 3 liters 2 liters 1 liter -

GEAR OIL 1 liter 1 liter 1 liter 1 liter 1 liter/wk. 2 liters/wk. -

GREASE 2 lbs. 1 lb. 1 lb. 1 lb. 2 lbs./wk. 1 lb. 0.5 lb. -

OIL # 10 1 liter 1 liter 1 liter 1 liter 1 liter 1 liter -

Crane - minimum of 2 piles/day ( 16 m. length including spotting ) VOLUME OF TRENCH CU.M. Soil Type

7

7-10

10-13

In these cases, the work is split over two or more days. First, the trench should be excavated and then the preparation of the bed, the laying, backfilling and compaction is done. Only 3 times. Therefore the volume of the excavation has to be limited following rates and then applicable: Soil Type a) hard soil b) very hard, stony

Productivity 3.50 cu.m./man-day 2.00 cu.m./man-day

After completion of the trench approximately 4 man-days are needed to lay 6 rings, backfill and compact to finish road level.

I. MECHANIZED ASPECT A. CLEARING & GRUBBING Dozer Horse Power 120 140 160 180 200

Production Dense of Vegetation ( No. of Trees/Hectares ) 51-100 101-200 250 190 290 220 330 255 375 285 420 310

0-50 360 420 480 540 600

B. EXCAVATION ( Common Materials ) B.1 CRANE Tonnage's 15 20 25 30 B.2 DOZER Horse Power 120 140 160 180 200

Canal 15 20 25 30

Capacity ( cu.m. /hr. ) Bank Volume Structure 10 15 20 25

Creek 10 15 20 25

Production ( cu.m./hr. ) Bank Volume Canal Structure 30 15 35 20 40 25 45 30 50 35

B.3 BACKHOE Bucket ( cu.m.) 0.5 0.75 1 1.25 1.5

Canal 20 30 40 50 60

Production ( cu.m./hr.) Bank Volume Structure 15 20 30 40 45

Creek 15 20 30 40 45

140 160 180 200

Common 55 60 65 70

Production ( cu.m./hr.) Bank Volume Aggregate 60 65 70 75

Cobbles/Boulders 27 29 31 33

Common 50 75 100 125 150

Production ( cu.m./hr.) Bank Volume Aggregate 55 80 110 135 165

Cobbles/Boulders 35 55 75 90 110

C. QUARRYING Dozer ( H.P.)

D. LOADING Bucket (cu.m.) 1 1.5 2 2.5 3 E. SPREADING Grader ( H.P.) 80-100 100-125 125-150 150-175 F. SIDE BORROW ( Common Materials) Dozer ( H.P.) 140 160

Road ( cu.m./hr. ) cmp. Common Aggregate 60 70 70 80 90 100 100 110

Production ( cu.m./hr.) Compacted Volume 35 40

201-250 160 185 210 240 265

251& > 130 150 170 195 215

180 200

45 50

G. STR BACKFILL WITH SPREADING & COMPACTION Dozer ( H.P.) 140 160 180 200

Production cu.m./hr. Compacted Volume 50 70 80 90

H. EMBANKMENT COMPACTION Tons 10 12 15 I. LOADING, SPOT & MANEUVER TIME Using Loader with 1,00 cu.m. Bucket Dump Truck Capacity 4.00 cu.m. 6.00 cu.m. 8.00 cu.m.

Capacity ( cu.m./hr.) Compacted Volume Self- Propelled Tam. Foot drum Vib. Drum 80 60 90 70 120 90

Compacted Volume of Common Materials Road Surface Materials 7 min. 7 min. 9 min. 9 min. 11 min. 11 min.

J. AVERAGE SPEED OF DUMP TRUCK Type of Road With load 35 30 20

Concrete/Asphalt Road Good Maintained Gravel Road Poorly Maintained Gravel Road

Cobbles/ Boulders 10 min. 12 min. 15 min.

Kilometer per hour Without load 45 35 25

K. DEMOLITION OF CONCRETE 160 CFN Compressor & two (2) Jack Hammer Capacity - 8.00 cu.m./day for massive concrete - 12.00 cu.m./day for slab & wall L. DRIVING OF PILES Steel Pipes : Crane 25 tons with 2-tons drop hammer, Capacity= 8 L.M./Hr. Concrete Piles : Crane 25 tons with 2500 kgs.m. Pile hammer, Capacity= 2.00 L.M. per Hr., 4.00 L.M./Hr. for thick & thin concrete piles. M. MANUAL ASPECT A. EXCAVATION A.1. Common Materials Capacity (cu.m./day) Bank Volume & Depth of Excavation ( meter ) 3.00 2.50 2.00 2.50 2.00 1.75 2.00 1.75 1.50

Type of Work Farmditchs Canal Structure A.2. Slight hard materials (lnd.) Type of Work Canal Structure B. LOADING CAPABILITIES OF FIVE ( 5) LABORERS Sand and Gravel cu.m./hr. 4 C. UNLOADING CAPABILITIES OF FIVE ( 5 ) LABORERS Sand and Gravel cu.m./hr. 6 D. CUT, BEND & PLACE RSB Structure Canal & Others

Capacity ( cu.m./day/man) Bank Volume 1 0.75

Common cu.m./hr. 5

Cobbles cu.m./hr. 3.5

Boulders cu.m./hr. 3

Cement bags/hr. 300

Common cu.m./hr. 6

Cobbles cu.m./hr. 5

Boulders cu.m./hr. 4

Cement bags/hr. 300

1 Steelman & 1 Helper with Bar Cutter 80 kgs/day

E. QUARRYING Capability Sand & Gravel 3.5

cu.m./day/man Cobbles 2.5

F. DEMOLITION OF CONCRETE Slab & Wall Massive Concrete

0.50 cu.m./man-day 0.20 cu.m./man-day

G. SCREENING OF AGGREGATES Gravel Sand

4.00 cu.m./day/man 6.00 cu.m./day/man

Boulder 2

R.S. Bars kgs./hr. 6,000

R.S. Bars kgs./hr. 7,000

Lumber bd,ft./hr. 4,000

Lumber bd.ft/hr. 4,000

H. MANUAL BACKFILL Capacity : 3.00 cu.m./day/man I. LAYING OF MATERIALS ( cu.m./day/man) Cobbles - 2.00 Boulders - 1.50 J. SPREADING OF AGGREGATE Capacity : 2.50 cu.m./day/man K. RUBBLE MASONRY ( Concreting ) Crew : 1- Foreman, 2- Mason, 10- Laborers, & 1- L.E. Operator Capacity : 6.00 cu.m./day L. GROUTED RIPRAP Crew : 1- Foreman, 2- Mason, 10- Laborers, & 1- L.E. Operator Capacity : 7.50 cu.m./day M. C.H.B. : Setting Capacity sq.m./day Crew : 1- Mason, 2- Laborers 4" CHB 6"CHB

Fence 14 10

Building 10 8

N. CONCRETE LINING 1- Foreman, 2- Mason, 1- L.E. Operator, 10- Laborers with one (1) bagger mixer Capacity : 4.50 cu.m./day O. INSTALLATION OF STEEL GATES Crew : 1- Mason & 5 - Laborers 16 x 16 to 24 x 24 Above 24 x 24

2 assy/day 1 assy/day

P. CONCRETE WORKS P.1. Fabrication, Placing & Dismantling of Forms Crew : 2- Carpenters & 4- Laborers; Capacity : 3.50 cu.m./day for 3000 psi Crew : 1- Carpenter & 1- Laborer; Capacity : 4.50 cu.m./day Canal Lining

Class A Concrete

P.2. Concreting and Curing Capability P.2.a. With concrete mixer Crew : 1- Foreman, 2- Mason, 1- L.E. Operator, & 8- Laborers Class "A" : 3.50 cu.m./day Class "B" : 4.50 cu.m./day Class "C" : 4.80 cu.m./day Lean Concrete : 6.00 cu.m./day

Concrete Mixer Laborer Operator Mason Foreman

8 1 2 1

P.2.b. Without concrete mixer Crew : 1- Foreman, 2- Mason, & 10- Laborers Class "A" : 2.50 cu.m./day Class "B" : 3.70 cu.m./day Class "C" : 4.80 cu.m./day Lean Concrete : 4.50 cu.m./day Q. PLASTERING OF CHB WALL Crew : 2- Mason, & 2- Laborers Capability : 12 sq.m./day (one side only) R. REINFORCED CONCRETE PIPES Crew

Capability Diameter

1- Foreman 1- Mason 1- Carpenter/ Steelman 12- Laborers with 1- Bagger Mixer

inch 12 18 24 30 36 48 42

Cm. 30 46 61 76 91 122

Fabrication 15 11 9 6 5 3 4

Installation 16 14 12 10 8 6 7

Max. Aggre. Size, in.

Cement bag/cu.m.

Sand cu.m./cu.m.

Gravel Boulder cu.m./cu.m. cu.m./cu.m.

1.50 2.00

9.00 7.00

0.45 0.50

0.90 1.00

-

1.00

7.5

0.48

0.96

-

-

4.50 4.20 5.00

0.225 0.35 0.50

0.45 0.05 0.10 1.00

0.75 1.00 1.00 -

NOTE : TIME OF MIXER/DAY = BAGS OF CEMENT/DAY X 10 MIN./ BAG 60 MINUTES/HOUR III. MATERIAL ASPECT Class Strength A. Concrete a. 211 kgs. e b.200 kgs e Canal Lining 200 kgs e B. Rubble Mason w/ 211 kgs e 211 kgs e C. Grouted Riprap Plain Riprap D. Lean Concrete

1000 psi E. Gravel Blanket F.Filter Drain

-

OTHER MATERIALS Class

Type of Structure Bridge/ Flume Siphon/Box Cul Other Str. @ me

A A A A B A B A

-

-

1.00 -

-

Strength kgs e 211 211 211 211 200 211 200 211

F. Lumber bd.ft./cu.m. 40 25 25 5 5 15 5 5

1/2 pl.wd pcs/cu.m. 1.00 1.25 1.25 0.10 0.40 0.40 -

Tie wr. kgs./cu.m. 1.25% RSB 1.20% RSB 1.10% RSB 1.00% RSB 1.00% RSB -

Nail kgs./cu.m. 2.50 2.00 2.00 0.50 0.25 1.50 0.50 0.25

G.I. Sheet Pc. 0.12 0.19 0.24 0.30 0.34 0.40.

F. Lumber Bd.ft. 0.34 0.36 0.48 0.60 0.72 0.84

Tie Wire kgs. 9.28 7.72 9.75 23.22 50.43 60.84

R.S.B. kgs. 3.65 4.52 5.26 6.01 6.79

F. Lumber Bd.ft. 2 2 3 3 4 4

CWN & TW kgs. 0.2 0.2 0.3 0.3 0.4 0.4

REINFORCED CONCRETE PIPES Diameter Inches 12 48 24 30 36 42 INSTALLATION OF R.C. PIPES Diameter Inches 12 18 24 30 36 42 PLASTERING C.H.B. BLOCK Size 4" & 6" G. I. LAYING OF C.H.B. Size 4" 6" RECOMMENDED INDIRECT COST Estimated Direct Cost ( E.D.C.) Up to 1 Million Above 1M to 5M Above 5M to 10M Above 10M to 20M Above 20M to 50M

Cement Bag 0.58 1.22 1.82 2.56 3.33 4.26

Sand Cu.m. 0.22 0.05 0.08 0.11 0.14 0.18

Cement Bags 0.21 0.45 0.72 0.93 1.11 1.32

Sand Cu.m. 0.01 0.02 0.03 0.04 0.05 0.06

Materials per sq.m. for two ( 2 ) sides Sand 0.034

Cement Bag/sq.m.

Fabrication Materials per pc. Gravel Cu.m. 0.05 0.10 0.15 0.21 0.28 0.36

Gravel Cu.m. 0.02 0.04 0.06 0.08 0.1 0.12

Cement 0.41

Sand Cu.m./sq.m. 0.55 1.07

0.046 0.089

Indirect Cost for OCM & Profit Max. Ranges O.C.M. % of E.D.C. C.P. % of E.D.C. 13% 15% 12% 14% 12% 14% 11% 12% 11% 12%

equal to or less than the total COA estimate plus 10% in order to sustain a finding of reasonableness otherwise the contract price will be deemed excessive.

Operated Equipment Bulldozer Payloader Road Grader Dump Truck Road Roller Crane Back Hoe Transit Mixer Air Compressor Plate Compactor Asphalt Paver/Finisher Asphalt Distributor

ACEL RATE 1998 Description Rate/Day Komatsu, D80A - 12DD, 180 Hp P 9,160.00 75 TCM /Clark, 1.53 cu.m., CapaP 10,010.00 Mitsubishi MG 500 170 Hp P 8,808.00 Japan & Other Make, 10 cu.m. CP 9,016.00 Ingersoll Rand SP48 MI Tons P 8,701.00 All models,Truck mounted, standP 11,296.00 Komatsu PC 120, Capacity 90 H P 9,656.00 Japan make 3.8 cu.m., 46 cu.m. P 8,528.00 Gas/Diesel Engine, CFM 20 Hp P 1,376.00 12 Hp Engine Driven P 1,648.00 Worthington 34 ( basic EquipmentP 3,320.00 Little Ford Sprasmaster P 5,784.00

Bare Equipment Pile Hammer (w/o crane) Drop Hammer (w/o crane) Jack Hammer Welding Machine Concrete Mixer Concrete Vibrator Chainsaw Water Truck Water Pump

Description Rate/Day Domag D8 - 22 P 5,067.00 Two tons w/ Pile Hammer P 100.00 Stanley, Hydraulic w/o power uniP 294.00 Gas/Diesel Driven 250 Amps., 1 P 300.00 1- Bagger P 298.00 Gas or Diesel Driven P 341.00 Nusquama, 2100 CD w/o Blade P 180 All Makes, 500-1000 Gals P 1,773 All Models 3.5"-4" size P 199.00

Mobilization 2% 2% 2% 2% 2%

Concrete Batch Plant

With Cement Silo Manula or Aut P 5,113.00/ month x rated Cap. Ln.cu.m/hr LABOR OUTPUT CAPABILITIES

REMOVAL EXISTING STRUCTURES: Lumpsum Installation: Timber: Girts and Girder Floor Joist Flooring Boards Post Walling/Siding: Covering Framing, Studs ( Multiply by the no. of days Double walling ) Ceiling Joist and Hangers Ceiling Boards ( 4' x 8' Plywood ) Windows sashes: Jambs Fabrication Frames Fabrication Jambs Installation Frames Installation Doors: Jambs Fabrication/ Installation Door Fabrication/Installation Paintings: Paint Rollers Paint Brush Neutralizer Truss Fabrication Purlins Installation Fascia Boards Roof Coverings ( G.I. sheets ) Concrete Works: Concrete Pouring Rebars Finishing: Rough Finish Plain/Fine Finish CHB Filling/Laying

0.10 - 0.15 cu.m./man-days 150 L.M./man-days 15 - 18 sq.m./man-days 0.14 cu.m./man-days 30 sq.m./man-days 12 cu.m./man-days

16 sq.m./man-days 30 sq.m./man-days 4 sq.m./man-days 2 sq.m./man-days 14 sq.m./man-days 10 sq.m./man-days 2.5 sq.m./man-days 1panel/man-days

125 sq.m./man-days 50 sq.m./man-days 100 sq.m./man-days 0.25 truss/man-days 60 L.M./man-days 0.05 cu.m./man-days 35 pcs./man-days 0.30 cu.m./man-days 20 - 30 kgs.man-days 16' 8" 6" 4"

10 sq.m./man-days 8 sq.m./man-days 6 - 8 sq.m./man-days

A. CEMENT MORTAR

0.4064 0.2032 0.1524 0.1016

6"x16"

Table- 1. Quantity of Cement and Sand for CHB Mortar per Square Meter Wall Size of CHB No. per sq.m. 4 x 8 x 16 6 x 8 x 16 8 x 8 x 16

B 0.525 1.013 1.500

12.5 12.5 12.5

40 Kg. Mixture Cement Bags C 0.394 0.759 1.125

1. Find the area of the wall Area = 3.00 x 4.00 A = 12 sq.m. 2. Refer to Table -1 along 4 x 8 x 16 CHB cement class "B" mixture; Multiply: Cement : 12 x 0.525 = 6.3 say 7 bags Sand : 12 x 0.0438 B. MORTAR FOR PLASTERING Table- 2 Quantity of Cement and Sand for Plastering per Square Meter Mixture Class A B C D Sand

1. Find the area of the wall ( two faces ) Area = 3.00 x 4.00 x 2 faces A = 24 sq.m. . Refer to Table - 2 under 16 mm. thick plaster class "B" mixture; Multiply; Cement = 24 x 0.192 = 4.6 bags Sand = 24 x 0.016 = 0.384 cu.m. C. CHB FOOTING

16 mm. thk. 0.288 0.192 0.144 0.120 0.016

40 kg. Cement Bags 20 mm. thk. 0.360 0.240 0.180 0.150 0.020

25 mm. thk. 0.450 0.300 0.225 0.188 0.025

D 0.328 0.633 0.938

m m m m

0.06193536 sq.m.

Sand 0.0438 0.0844 0.1250

e- 3. Quantity of Cement, Sand, and Gravel for CHB Footing per Meter Length Dimension Centimeters t 10 10 10 10 15 15 15 15 20 20 20

w 30 35 40 50 40 45 50 60 40 50 60

Cement in Bags Class Mixture 40 Kg. Cement A 0.27 0.315 0.36 0.45 0.54 0.608 0.675 0.81 0.72 0.9 1.08

B 0.225 0.263 0.3 0.38 0.45 0.506 0.563 0.675 0.6 0.75 0.9

1. Solve for the net length of the CHB wall Net length = 40 m - ( 0.25 x 11 post ) = 37.25 meters 2. Refer to Table - 3 along the 15 x 50 cm footing dimension 40 Kg. Cement class "A" Mixture; Multiply : Cement : 37.25 x 0.675 = 25.14 say 26 bags Sand : 37.25 x 0.038 = 1.4 say 1.5 cu.m. Gravel : 37.25 x 0.075 = 2.8 say 3.0 cu.m. TECHNICAL SERVICES DIVISION PERSONNEL Celso U. Reyes

Florenda T. Lonio

Santiago O. Burdeos

Junrey E. Labatos

Ronnie Valentino U. Tello

Joehl Francisco E. Duarte

Dante M. Jabutay

Alfredo Genaro C. Quintos

Charito A. Samson

William C. Peguit

Joseph P. Cagampang

Alan G. Milan

MAINTENANCE BY CONTRACT ( MBC ) METHODS OF CONSTRUCTION 1. PATCHING POTHOLES - Should be done to the areas specified by the contracts and plans duly approved by the Engineers. Materials to be used must be suitable to acquire best result when compacted. SCHEDULE OF WORKS : MONTHLY 2. RESHAPING should also be done to areas required in the plan and contracts. All works should conform to what will be described in the specification. SCHEDULE OF WORKS : QUARTERLY 3. VEGETATION CONTROL AND CLEANING DITCHES areas should be removed and cleared. SCHEDULE OF WORKS : TWICE A YEAR

All objects subject for the obstruction of the designed

4. REGRAVELLING - All materials shall consist of hard, durable particles or fine divided mineral matter that can be compacted reaching for stable sub-base. Using especially equipped vehicles material should be distributed in a continous uniform layer. The uniform thickness of sub-base material shall be adjusted prior to the compaction by watering or by drying as required in order to obtain the required compaction. Compaction shall continue until a field density of at least 100 per cent of the maximum dry density. SCHEDULE OF WORKS : ANNUAL 5. BLADING/GRADING - All unstable materials should be removed in areas subject for Blading/Grading. These areas should be brought to a grade required in the plans and contracts. Compaction will follow using heavier compacting units until required density can be obtained. SCHEDULE OF WORKS : ANNUAL

Aggregate Sand Gravel Cu.m. Cu.m. 0.015 0.03 0.018 0.035 0.02 0.04 0.02 0.05 0.03 0.06 0.034 0.068 0.038 0.075 0.045 0.09 0.04 0.08 0.05 0.1 0.06 0.12

Type of Equipment 1. Bulldozer (108)

2. Road Grader 3. Payloader 4. Crane Shovel 5. Sheep Foot Roller 6. 3- Wheel Road Roller 7. Tractor Drawn Roller 8. Tandem Roller 9. 9 1/2 T Dump Truck

10. 2 1/2 T Dump Truck

11. Buggy 12. Wheel Borrow 13. Water Tuck 14. Conrete Mixer 15. Rock Crusher 16. Conrete Virator 17. Concrete Floor Finisher 18. Percussioned Drilling

EQUIPMENT CAPABILITIES Average Capabilities (a) Clearing (b) Stripping © Excavation: 1. Common soil 2. Slightly Hard Materials (d) Quarrying: 107 Common Materials 108 Aggregate Boulders 200 Needs Screening (e) Pushing (a) Subgrading (b) Spreading (a) Loading (a) Loading (a) Satic rolling ( 12 passes- 15 cm. lift (b) Vibratory Rolling ( 4 passes- 15 cm. lift) (a) Static Rolling ( 6 passes- 20 cm. lift) (a) Vibratory Rolling (6 passes- 20 cm. lift) (a) Static Rolling ( 6 passes- 20 cm. lift) (b) Vibratory Rolling (6 passes- 60 cm. lift) (a) Hauling Common Borrow Base Course (b) Hauling Selected Borrow Base course © Hauling Concrete Batch Class 'A' (a) Hauling Common Borrow Base Course (b) Hauling Selected Borrow Base course © Hauling Concrete Batch Class 'A' (a) Hauling Concrete Mix (a) Hauling Aggregates (b) Hauling Concrete Mix (a) Watering (a) Mixing Concrete (a) Crushing Mixed Sand & Gravel (a) Vibrating Concrete Mix (a) Finishing Concrete Floor (a) Drilling Hard Rock (b) Drilling Loose Rock © Drilling Limestone (d) Drilling Sticky Clay (e) Drilling Loose Clay

500 sq.m./hr. 200 sq.m./hr. 45 cu.m./hr 25 cu.m./hr. 50 cu.m./hr. 40 cu.m./hr. 15 cu.m./hr. 3 cu.m./hr. 300 sq.m./hr. 50 cu.m./hr. 30 cu.m./hr. 35 cu.m./hr. 15 cu.m./hr. 135 cu.m./hr. 24 cu.m./hr. 24 cu.m./hr. 24 cu.m./hr. 72 cu.m./hr. 3.5 cum./hr. 5.0 cu.m./hr. 2 Batch/trip 2.5 cu.m./trip 4.0 cu.m./trip 1 Batch/trip 0.17 cu.m./trip 0.17 cu.m./trip 0.05 cu.m./trip 1,000 sq.m./trip 9 cu.m./hr. 30 cu.m./hr. 40 cu.m./hr. 140 cu.m./hr. 0.23 m./hr. 0.30 m./hr. 0.38 m./hr. 0.49 m./hr. 0.70 m./hr.

Table 1: RENTAL RATES & CAPABILITIES DESCRIPTION

WORKING HOURS PER DAY=8 HRS. OPERATED PER HOUR

Asphaltic concrete Plant (Php 4824/mo. X Rated Cap. In Cu.M./Hr = (4826/30 X 8 hrs X 60.0 Tons) = PhP 77,184.00 Portable Concrete Batching Plant (Php 6216/mo. X Rated Cap. In Cu.m. ={(6,216/30) X [(8 X 60) / 30] X 5.0 Cu.M. } = Php 16,576 per Day Rock Crusher Portable Parker Php !,556.55 Bulldozer Komatsu D65A-8 Php2,090.00 Bulldozer with Ripper + 35% Php2,808.00 Backhoe Crawler MS180 Php1,748.00 Backhoe Crawler with Breaker + 35% Php2,359.80 Backhoe Crawler PC200-3 Php1,814.00 Loader Crawler Komatsu D-60S-7/DD Php1,418.00 Loader Whell TCM/ Clark 75B Php1,255.00 Road Grader MG500 Php1,101.00 Roller Bomag BW210DH Php1,398.00 Crane Crawler Type Php2,041.00 Crane Truck Mounted Php2,095.00 Crane Hydraulic Php2,452.00 Hammer Diesel MH25 Php1,018.00 Hammer diesel MH35 Php1,284 Hammer Vibratory Php565.00 Transit Mixer 8-10 CU DYS Php1,486.00 Concrete Mixer (1Bagger) Php156.00 Concrete Paver Roller Screed Php3,152.00 Concrete Vibrator Gasoline Php78.13 Concrete Saw Gasoline Self Propelled Php332.03 Plate Compactor (Vibratory) Php150.67 Air Compressor 161-185 CFM Php422.00 Jack Hammer/ P. Breaker Php322.00 Bar Shear/ Cutter Php368.30 Bar Bender Php418.53 Water Pump Diesel Php119.90 Wekding Machine Electric Driven/ DC ouPhp355.00 Oxy-Acetylene/Cutting outfit Php64.00 Chainsaw w/out blade Php561.25 Generator Set Php126.42 Dumpt truck (12-15 cu.Yds) Php1,127.00 Water Truck ( 5000-6000 Gals) Php1,794.00 Trailer 60 Ton PhP4.25/HR./Km Php9,562.50 ( PhP 4.25 X Wt. (Min.=15T) X No. of KM. + 50% Surcharge, Return trip Example (100KM) = (4.25 X 15 X 100) X 1.5 = PhP 1 Cargot Truck ( 9-10 Tons) Php918.00

ORKING HOURS PER DAY=8 HRS.

COMPUTED RENTAL RATES RATES PER DAY Php77,184.00 Asphalt Batching Tons) = PhP 77,184.00 Php16,576.00 30 Min/Batch 0] X 5.0 Cu.M. } = Php 16,576 per Day Php12,452.40 Crushing Aggregates Php16,720.00 Quarrying Php22,464.00 Quarrying Php13,984.00 Excavation Php18,878.00 Excavation Php14,512.00 Excavation Php11,344.00 Loading Php10,040 Loading Php8,808.00 Spreading Php11,184.00 Compacting Php16,328.00 Lifting / Pile Driving Php16,760.00 Lifting / Pile Driving Php19,616.00 Lifting / Pile Driving Php8,144.00 Pile Driving Php10,272 Pile Driving Php4,520 Pile Driving Php11,888.00 Concrete Transport Php1,248.00 Concrete Mixing Php25,216.00 Concrete Paving Php625.04 Concrete Vibration Php2,656.24 Concrete Cuttung Php1,205.36 Compacting Php3,376.00 Power Generation Php2,576.00 Breaking Php2,946.40 Bar Cutting Php3,348.24 Bar Bending Php959.20 Water Pumping Php2,840.00 Weilding / Cutting Php512.00 Cutting Php4,490.00 Cutting Php1,011.36 Power Generation Php9,016.00 Hauling / Transporting Php14,352.00 Water Supply Php76,500.00 Transporting trip Example (100KM) = (4.25 X 15 X 100) X 1.5 = PhP 16,576 per Day Php7,344.00 Hauling / Transporting

CAPABILIT

CAPABILITIES 60 Tons

TONS

5.00 Cu.M.

Cu.M.

100 50 50 0.8 0.8 0.8 1.8 1.53 50 11 46-50 46-50 46-50 7500 10500 9.17 6.12-7.65 10-Jun

TONS Cu.M. Cu.M. Cu.M. Cu.M. Cu.M. Cu.M. Cu.M. Cu.M. TONS TONS TONS TONS Kg.-M. Kg.-M. Cu.M. Cu.M.

50 mm Max 6 3/4

Depth

161-185

CPM

Max 32mm Max 32mm 900 500

G40 G40 LPM APMS

64-125 9.17-11.46 5000-6000 15

KVA Cu.M. Gals. TONS

9-10

TONS

Per Day Per Batch Per Hour Per Hour Per Hour Capacity Capacity Capacity Capacity Capacity Per Hour Capacity Capacity Capacity Capacity Rated Energy Rated Energy Capacity Per Hour

Capacity Capacity Capacity Capacity Capacity Capacity

51-100 HP Capacity Capacity Capacity Capacity

Excavation (0.75 cu.m./man-day)

brush roller

Form Works (Gang Output: 3.5 cu.m./day)

skilled unskilled

Steel Works (Gang Ouput: 80 kgs/day)

skilled unskilled

Concrete Works (Class A) (Gang Output: 3.5 cu.m./day)

skilled unskilled

Plastering (Gang Output: 12.0 sq.m./day)

skilled unskilled

Market Size (mm)

2 4

8 mm 1 1

10 mm 12 mm

3 9

16 mm 20 mm

2 2

25 mm

Painting 125 sq.m./man-days 50 sq.m./man-days 87.5

Plastering Class A B C D

CHB Sizes cm 10 x 20 x 40 15 x 20 x 40 20 x 20 x 40

4" 6" 8"

Diameter

Radius

Lenth

(m)

(m)

(m. / pc))

Cross-sectional Area (sq.m.)

Standard

Grade 40

Volume

Weight

Weight

(cu.m. / pc.)

(kgs. / pc)

(kgs. / pc)

0.008

0.0040

6.00

0.0000502

0.000301

2.351

0.010

0.0050

6.00

0.0000785

0.000471

3.674

3.696

0.012

0.0060

6.00

0.0001130

0.000678

5.290

5.328

0.016

0.0080

6.00

0.0002010

0.001206

9.405

9.468

0.020

0.0100

6.00

0.0003140

0.001884

14.695

14.796

0.025

0.0125

6.00

0.0004906

0.002944

22.961

Average Unit Weight of Steel =

Mixture 1:02 1:03 1:04 1:05

40kg bag cu.m. Cement Sand 18 12 9 7.5

1 1 1 1

7,800.00 kgs/cu.m.

45

165.32

REVISED MANHOLES [8 units revised to 11 units] Qty I MANHOLES Concrete Volume

Unit

Unit Cost

Total Cost

5.68 cu.m.

Concrete Works Portland Cement Sand Gravel

52.00 bags 4.00 cu.m.

240.00 300.00

12,480.00 1,200.00

4.37 cu.m.

500.00

2,186.80

15,866.80 Plastering Portland Cement Sand

13.00 bags 0.70 cu.m.

240.00 300.00

3,120.00 211.20 3,331.20

130.00 80.00 6,955.20 2,093.00

23,400.00 2,720.00 34,776.00

Steel Works RSB 10.00mm dia Tie Wire #16

180.00 34.00 5.00 1.00

Steel Plate 1/4 thk Angle Bar 2" x 2" x 3/16" Labor Excavation

pcs kgs sheets pc

Men 5.00 laborer 3.00 mason 2.00 steelman 5.00 laborer

Skilled Unskilled

Rate 252.00

Days 2.00

330.00 330.00 252.00

5.00 2.00 6.00

2,520.00 4,950.00 1,320.00 7,560.00 13,830.00

TOTAL COST FOR MANHOLES [Revised]

98,537.00

Original Manhole Cost Variance

67,911.46 30,625.54 8.00 67,911.46

x

DRAINAGE [Additional Cost] Concrete Volume I

2,093.00 62,989.00

DRAINAGE I (Bldg 1&2)

Qty

Unit

11.00

x 93,378.25 5,158.75

Unit Cost

Total Cost

Concrete Volume (Flooring)

19.20 cu.m.

Concrete Works (Flooring) Portland Cement Sand Gravel

172.80 bags 11.14 cu.m. 14.78 cu.m.

240.00 300.00 500.00

41,472.00 3,340.80 7,392.00

52,204.80 CHB

3,149.00 pcs

Mortar Portland Cement Sand

584.00 bags

Plastering Portland Cement Sand Steel Works RSB 12.00mm dia RSB 10.00mm dia RSB 25.00mm dia Tie Wire #16 Welding Rod

12.00

37,788.00

240.00

140,160.00 14,584.32 154,744.32

48.61 cu.m.

300.00

166.00 bags 9.22 cu.m.

240.00 300.00

39,840.00 2,764.80 42,604.80

232.00 pcs 160.00 pcs

250.00 130.00

58,000.00 20,800.00

178.00 pcs 91.00 kgs 10.00 kgs

500.00 80.00 80.00

89,000.00 7,280.00 800.00

175,880.00 Labor Excavation (160.00 cu.m.) (3.5 cu.m./man-day)

Men

Skilled

Rate

Days

9.00 laborer

252.00

5.00

11,340.00

4.00 mason 4.00 steelmen

330.00 330.00

7.00 7.00

9,240.00 9,240.00

29,820.00 SUB-TOTAL 1 II

PIPE CULVERT (Total Length = 223.00 m) Pipe Culvert Portland Cement Sand

493,041.92 Qty

Unit 223.00 pcs 7.00 bags 0.40 cu.m.

Unit Cost

Total Cost 334,500.00 1,680.00 120.60

1,500.00 240.00 300.00

336,300.60 Labor Skilled Unskilled

3.00 mason 5.00 laborer

330.00 252.00

2.00 2.00

1,980.00 2,520.00

4,500.00 SUB-TOTAL 2

340,800.60

TOTAL COST FOR DRAINAGE

833,842.52

TOTAL ADDITIONAL COST

932,379.52

RSB Weight

Quantity Computation - Manholes Concrete Volume 1-5 L Walls 1.10 Floor 1.20

6-10 Walls Floor

L 0.90 1.00

W 1.00 1.20

T 0.10 0.10

W 1.00 1.00

T 0.10 0.10

Total Concrete Volume for 661.28 kgs

RSB Utilization 1-5

hor

ver

L

Walls Cover Floor

8.00 8.00 8.00

8.00 8.00 8.00

1.20 1.20 1.20

Walls Cover Floor

7.00 7.00 7.00

7.00 7.00 7.00

1.00 1.00 1.00

6-10

31.08%

Total required len

Manhole Cover Steel Plate feet L 8' W 4' Area

Manhole Cover Handle

meters 2.44 1.22 2.98

Required Cover Area 1-5 6-11

Angle Bar Require Length

L

pcs 0.30

total 11.00

Required Angle bars

3.30 1.00

Quantity Computation - Drainage Reference Equiv Scale Actual L 1-2 5.00 5.00 25.00 2-3 1.20 5.00 6.00 3-4 10.20 5.00 51.00 5-6 10.60 5.00 53.00 6-7 2.10 5.00 10.50 145.50 Total Length of Access Road Drainage 286.00 Total Length of Drainage with Pipe Culvert 223.00 1,227.34 kgs 587.81 kgs 4,087.10 kgs

Bldg 1 Bldg 2 Comm's Quart Power Med/Den Total

WEIGHT (%) By Length By Volume 31.25% 31.25% 31.25% 31.25% 11.25% 11.25% 15.00% 100.00%

11.25% 11.25% 15.00% 100.00%

12mm 10mm

6,563.54 kgs

pcs 4.00 1.00

pcs 4.00 1.00

total 0.44 0.14 0.58

Surface Area per area walls pcs 1.00 4.00 5

2.92

total 0.36 0.10 0.46

6

2.76

otal Concrete Volume for Manholes

RSB pcs

pcs

16.00 16.00 16.00

14.00 14.00 14.00

5.68 cu.m

total 4.00 1.00 1.00

4.00 1.00 1.00

76.80 19.20 19.20 115.20

56.00 14.00 14.00 84.00

8

5.00

576.00

6.67

6.00

504.00

Total required length of RSB

1,080.00 m.

Total pieces required vol

180.00 pcs 0.34 2,647.00 kgs

Required Cover Area L W 1.20 1.00

1.20 1.00

pcs 5 6

Required steel plates

total area 7.20 6.00 13.20 5.00 sheets

Total 11 44.00

m. pc

Drainage Around Buildings Building 1 L1 63.80 L2 36.20 100.00 Building 2 L1 63.80 L2 36.20 100.00

Commander's Quarter L1 18 L2 18 36 Power House L1 20 L2 16 36

Total Length for Building Drainage (with steel grating)

Concrete Volume for Flooring Only L W Vol 320.00 0.6 RSB Required Length H Ver bars 2.00 Hor bars

W 0.6

Medical Dental L1 L2

320.00

Total Length of Steel Grating Lengthwise Crosswise 640.00 426.67

Surface Area L H 640.00

T Total Vol 0.10 19.20 cu.m.

L 2.60 960.00

24 24 48

req' pcs req' L RSB pcs vol kgs 533.33 1,386.67 232.00 0.63 4,911.87 160.00 0.30 2,352.43 Total Weight

Required no.of CHB req' Ver 2.00 Hor 1,574.80 3,149.00

layers

Total Excavation Volume L W 200.00 0.80

pcs

Estimated Volume of Pipe Culvert Grout L W H 0.0008

0.90

Total 0.0030

0.67

H 1.00

7,264.30

Total 160.00 cu.m.

sq.m.

Crosswise

total L 1,066.67

Total 576.00 sq.m. 9,300.02

kgs

pcs req' 178.00 pcs #VALUE! cu.m. #VALUE! kgs