Teikoku Pump Refrigeration O&M Manual [PDF]

FOR REFRIGERATION APPLICATIONS . . Before Before operatingthe thecanned cannedmotor motorpump, pump,read readthis this"

35 0 1MB

Papiere empfehlen

![Teikoku Pump Refrigeration O&M Manual [PDF]](https://vdoc.tips/img/200x200/teikoku-pump-refrigeration-oampm-manual.jpg)

- Author / Uploaded

- Tally Land

Datei wird geladen, bitte warten...

Zitiervorschau

FOR REFRIGERATION APPLICATIONS

. . Before Before operatingthe thecanned cannedmotor motorpump, pump,read readthis this"Instruction "InstructionManual" Manual"and and"Caution "Cation operating Your Safety" avoid improper operation.It is It is essential your safety and Notes Notes forfor Your Safety" to to avoid improper operation. essential forfor your safety and avoiding disaster. avoiding disaster. . is imperative that the pump be shut down immediately if the bearing wear monitor . It It is that the pump be shut down thered bearing wear monitor is in the red. Operating the pump while theimmediately monitor is inifthe will void the is inimperative thewarranty. red. Operating the pump while the monitor is in the red will void the warranty.

__ 4 __

__

5

__

ABRIDGED STARTUP PROCEDURES (For further instructions, please see Section 5. “Installation and Operation”)

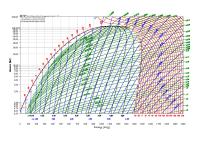

Sample Inspection Report

BEFORE YOU BEGIN x x x x x

Obtain a copy of the Teikoku Inspection Report (shown above) to verify flow conditions. Verify the liquid level in the vessel is sufficient to not cause dry running or cavitation. Verify the reverse circulation piping is per Teikoku’s “Reverse Circulation Piping Connection” as shown on the previous two pages. Verify the supplied reverse circulation orifice is installed between the reverse circulation flange at the rear of the motor and the reverse circulation piping. Verify that the number stamped on the orifice handle matches the product code on the pump nameplate.

PRIMING THE PUMP Step 1: Open the reverse circulation valve and discharge valve to 100% open Step 2: Open the suction valve to 100% open to fill the pump with liquid Step 3: Let pump fill for a minimum of ten (10) minutes to allow vapor to vent from pump and motor. On sub-freezing applications, wait until a layer of frost has developed on the entire motor before starting.

__

6 __

ROTATION CHECK Step 1: Pump must be primed before checking rotation. Step 2: Check if suction valve, discharge valve, and reverse circulation valve are all 100% open. Step 3: Start motor. If the Bearing Wear Monitor (TRG) swings immediately to the red, the pump is most likely running backwards. Stop the motor, reverse the leads, and then repeat rotation check. (Alternate Step 3: You should also check if the discharge pressure matches the ‘Teikoku Inspection Report’ curve. If it does, the pump is rotating correctly. If the discharge pressure is 65% or less than what is shown on the curve, the pump is rotating in the reverse direction. Swap the leads and repeat rotation check.) STARTING THE PUMP Step 1: Make sure the pump is primed and is running in the correct rotation. Also, verify that the suction valve and the reverse circulation valve is 100% open. Step 2: Close the discharge valve to 20% open Step 3: Start the motor. Step 4: Slowly open the discharge valve till you reach the desired flow rate. CHECKS DURING PUMP OPERATION x x x x

Pump should be operating without excessive noise or vibration. Compare the amperage draw to the Teikoku Inspection Report. If the amperage is above the values shown on the chart, close the discharge valve until the amperage drops. Confirm that the Bearing Wear Monitor (TRG) is running in the green (if bearings are new). Confirm the pump is running at the rated discharge pressure.

IMPORTANT: DO NOT OPERATE THE PUMP IF THE BEARING WEAR MONITOR IS RUNNING IN THE RED. DOING SO WILL VOID THE WARRANTY.

__

7 __

__ 8 __

__ 9 __

__ 10 __

__ 11 __

__ 12 __

REVERSE CIRCULATION TYPE (R-TYPE, VERTICAL CONFIGURATION)

__ 13 __

__ 14 __

PUMP CIRCULATION PATH

__ 15 __

__ 16 __

__ 17 __

__ 18 __

__ 19 __

__ 20 __

__ 21 __

__ 22 __

THIS PAGE IS INTENTIONALLY LEFT BLANK