883 Spare Parts Multilingual [PDF]

SECTION 8: SPARE PARTS 011003/02 SECTION 8: SPARE PARTS - CONTENTS 8.1 SPARE PARTS ORDERING PROCEDURE ...............

49 0 13MB

Papiere empfehlen

![883 Spare Parts Multilingual [PDF]](https://vdoc.tips/img/200x200/883-spare-parts-multilingual.jpg)

- Author / Uploaded

- victorhernandezrega

Datei wird geladen, bitte warten...

Zitiervorschau

SECTION 8: SPARE PARTS

011003/02

SECTION 8: SPARE PARTS - CONTENTS 8.1

SPARE PARTS ORDERING PROCEDURE .................................................................... SP - 2

8.2

SPARE PARTS ORDER FORM ...................................................................................... SP - 3

8.3.

SPARE PARTS INDEX ................................................................................................. SP - 18

SECTION 8: RESERVEONDERDELEN - INHOUD 8.1

RESERVEONDERDELEN EN BESTELLING .................................................................. SP - 4

8.2

BESTELFORMULIER ...................................................................................................... SP -5

8.3

INHOUDSOPGAVE RESERVEONDERDELEN .............................................................. SP -18

SECTION 8: PIÈCES DE RECHANGE - SOMMAIRE 8.1

PIÈCES DE RECHANGE ET APPROVISIONNEMENT.................................................SP - 6

8.2

FORMULAIRE DE COMMANDE ...................................................................................... SP -7

8.3

SOMMAIRE DES PIÈCES DE RECHANGE .................................................................. SP -20

SECTION 8: ERSATZTEILE - INHALT 8.1

ERSATZTEILE UND ERSATZTEILBESTELLUNG .......................................................... SP - 8

8.2

BESTELLFORMULAR .................................................................................................... SP - 9

8.3

INHALTSVERZEICHNIS ERSATZTEILE ...................................................................... SP - 20

CAPÍTULO 8: REPUESTOS - ASUNTO 8.1

REPUESTOS Y PEDIDO .............................................................................................. SP -10

8.2

FORMULARIO DE PEDIDO ............................................................................................ SP -11

8.3

ASUNTO: ...................................................................................................................... SP -20

KAPITEL 8: RESERVEDELE - INDHOLD: 8.1

BESTILLING AF RESERVEDELE .................................................................................. SP -12

8.2

BESTILLINGSSEDDEL .................................................................................................. SP -13

8.3

INDHOLDSFORTEGNELSE ........................................................................................... SP -20

KAPITTEL 8: RESERVEDELER - INNHOLD: 8.1

RESERVEDELER OG RESERVEDELSBESTILLING .................................................... SP -14

8.2

FORMULAR BESTILLING .............................................................................................. SP -15

8.3

INNHOLDSFORTEGNELSE RESERVEDELER ............................................................. SP -20

CAPITOLO 8: RICAMBI - SOMMARIO 8.1

RICAMBI E COME ORDINARLI .................................................................................... SP - 16

8.2 8.3

MODULO D’ORDINE RICAMBI ..................................................................................... SP - 17 INDICE DEI RICAMBI ................................................................................................... SP - 20

KAPITEL 8: RESERVDELAR - INNEHÅLL 8.1 8.2

RESERVDELAR OCH RESERVDELSBESTÄLLNING .................................................... SP-18 BESTÄLLNINGSBLANKETT .......................................................................................... SP-19

8.3

INNEHÅLL RESERVDELAR ........................................................................................... SP-20

SP-1

SECTION 8: SPARE PARTS

011003/02

8.1 SPARE PARTS ORDERING PROCEDURE

Ordering Procedure To ensure delivery of your parts, when ordering please quote: · machine serial number · illustration number and item number · part number · part description · quantity required EXAMPLE: If you wanted to order 1 Panfeeder Takeup Bearing, place your order in the following fashion : Machine serial number Illustration number - 8.3.4 Item number - 29 Part number - 11.05.0241 Part description - Tape up Bearing Quantity required - 1 This information will enable us to supply the correct parts with the minimum of delay.

NOTE: For ordering spare parts related to the engine, a parts list issued by the manufacturers has been included with this manual. Follow the procedure as laid down within this parts list.

SP-2

Machine Type

Machine Serial No.

MACHINE DETAILS

Illustration Number Item No.

MANUAL DETAILS Parts No. Part Description

Customer Address

Quantity Required

8.2

Customer Name

Parts Ordering Form

SECTION 8: SPARE PARTS

SPARE PARTS ORDER FORM

SP-3

011003/02

SECTION 8: RESERVEONDERDELEN

010303/01

8.1 Reserveonderdelen en bestelling

Voor een correcte bestelling van reserveonderdelen de volgende gegevens vermelden: · Serienummer van de machine · Tekening- en positienummer · Onderdeelnummer · Onderdeelaanduiding · Bestelhoeveelheid Voorbeeld: bestelling Serienummer van de machine Tekeningnummer -8,30,4 Positienummer -29 Onderdeelnummer -11.05.0241 Onderdeelaanduiding Bestelhoeveelheid - 1 Alleen zo kunnen wij u zo snel mogelijk het juiste onderdeel leveren.

Aanwijzing: Om onderdelen voor de motor te bestellen, is de onderdelenlijst van de motorfabrikant bijgevoegd.

SP-4

Type installatie Serienummer

Gegevens omtrent de machine

Tekeningnummer Positienummer Onderdeelnummer Onderdeelaanduiding

Gegevens omtrent het handboek

Adres

Datum

Bestelhoeveelheid

8.2

Naam

Bestelformulier

SECTION 8: RESERVEONDERDELEN

BESTELFORMULIER

SP-5

010303/01

SECTION 8: PIÈCES DE RECHANGE

010303/01

8.1 Pièces de rechange et approvisionnement

Pour obtenir un approvisionnement correct en pièces de rechange, sans retards, il faut préciser: · Numéro de série de la machine · Repère ou n° de plan · Référence de la pièce · Désignation · Quantité Exemple: COMMANDE Numéro de série de la machine Repère – 8.30,4 N° de plan -29 Référence de la pièce – 11.05.0241 Désignation Quantité - 1 Ces informations nous permettent de fournir la pièce voulue dans les meilleurs délais.

Important: Pour vos approvisionnements en pièces de rechange moteur, nous avons joint la liste des pièces de rechange du constructeur du moteur.

SP-6

N° de plan

Désignation

Référence de la pièce

Repère

Type de machine

Numéro de série

Informations sur le manuel opérateur

Adresse

DATE

Quantité

8.2

Informations sur la machine

Formulaire de commande Nom

SECTION 8: PIÈCES DE RECHANGE

FORMULAIRE DE COMMANDE

SP-7

010303/01

SECTION 8: ERSATZTEILE

010303/01

8.1 ERSATZTEILE UND ERSATZTEILBESTELLUNG

Für eine korrekte und reibungslose Ersatzteilbestellung nennen Sie uns bitte: · Seriennummer der Maschine · Zeichnungs- und Positionsnummer · Teilenummer · Teilebezeichnung · Bestellmenge Beispiel: BESTELLUNG Seriennummer der Maschine Zeichnungsnummer – 8.3.4 Positionsnummer - 29 Teilenummer – 11.05.0241 Teilebezeichnung – Bestellmenge - 1 Nur so ist es uns möglich Ihnen schnellstmöglichst das richtige Teil zu liefern.

Hinweis: Zur Bestellung von Ersatzteilen für den Motor ist die Ersatzteilliste des Motorherstellers beigefügt.

SP-8

Anlagentyp

Seriennummer Zeichnungsnummer

Angaben zur Maschine Positionsnummer

Teilenummer Teilebezeichnung

Angaben zum Betriebsbuch

Anschrift

Datum

Bestellmenge

8.2

Name

Bestellformular

SECTION 8: ERSATZTEILE

BESTELLFORMULAR

SP-9

010303/01

CAPÍTULO 8: REPUESTOS

010303/01

8.1 Repuestos y pedido

Para pedir los repuestos de forma correcta, hay que indicar: · Número de serie de la instalación · Número de dibujo y de posición · Número de la pieza · Denominación de la pieza · La cantidad requerida EJEMPLO: Pedido Número de serie de la instalación Número de dibujo – 8.3.4 Número de posición -29 Número de pieza –11.05.0241 Denominación de la pieza Cantidad requerida - 1 Solo de esta forma es posible abastecer lo más pronto la pieza exacta.

AVISO: Para pedir los repuestos del motor hay que referirse a la anexa lista de repuestos del constructor del motor.

SP-10

Tipo de la instalación

Número de serie

Datos de la máquina

Número de dibujo

Número de posición

Número de piezas

Dirección

Denominación de la pieza

Datos del manual

Fecha

Cantidad requerida

8.2

Nombre

Formulario de pedido

CAPÍTULO 8: REPUESTOS

FORMULARIO DE PEDIDO

SP-11

010303/01

KAPITEL 8: RESERVEDELE

010303/01

8.1 BESTILLING AF RESERVEDELE Bestillingsprocedure. Udfyld venligst følgende felter på bestillingssedlen: · anlæggets serienummer · illustrationsnummer og referencenummer · reservedelsnummer · reservedelsbeskrivelse · antal

EKSEMPEL: Hvis du vil bestille ONE HOPPER REAR CLAMP skal du skrive følgende: Anlæggets serienummer: FTP 500040 Illustrationsnummer: 8.3.15 Referencenummer: 12 Reservedelsnummer: 683.08.04 Reservedelsbeskrivelse: Hopper Rear Clamp Antal: 1 På den måde kan vi levere den korrekte reservedel hurtigst muligt.

BEMÆRK: Der er vedlagt en reservedelsliste fra motorfabrikanten til brug ved bestilling af reservedele til motoren. Følg ovennævnte bestillingsprocedure.

SP-12

Type

HÅNDBOGSSPECIFIKATIONER

Serienummer Illustrationsnr. Referencenr. Reservedelsnr.Beskrivelse

ANLÆGSSPECIFIKATIONER

Kundeadresse

Antal

Dato______________

8.2

Kundenavn

Bestillingsseddel

KAPITEL 8: RESERVEDELE

Bestillingsseddel

SP-13

010303/01

KAPITTEL 8: RESERVEDELER

010303/01

8.1 RESERVEDELER OG ESERVEDELSBESTILLING

For en korrekt og enkel reservedelsbestilling oppgi: · Seriennummer · Tegnings- og posisjonsnummer · Delnummer · Delbetegnelse · Bestillingsmengde EKSEMPEL: BESTILLING Seriennummer - FTP 500040 Tegningsnummer -8.3.4 Posisjonsnummer -29 Delnummer -11,050,0241 Delbetegnelse - Tape up Bearing Bestillingsmengde - 1 Bare på denne måten er det mulig for oss til å levere den riktige delen snarest mulig.

Henvisning: For bestilling av reservedeler for motoren er motorprodusentens reservedelsliste vedagt.

Anleggstype

Serienummer

Angivelser til maskinen

Tegningsnummer Posisjonsnummer Delnummer

Delbetegnelse

Angivelser til instruksjonsboken

Adresse

DATO

Bestillingsmengde

8.2

Navn

Formular bestilling

KAPITTEL 8: RESERVEDELER

FORMULAR BESTILLING

010303/01

CAPITOLO 8: RICAMBI

I 010303/01

8.1 RICAMBI E MODULO D’ORDINE

Per assicurarsi la consegna dei vostri ricambi, si prega di citare: · Numero di serie della macchina · Numero dell’illustrazione e della posizione · Numero del ricambio · Descrizione del ricambio · Quantità ESEMPIO: ORDINE Numero di serie della macchina Numero dell’illustrazione - 8.3.4 Numero della posizione - 29 Numero del ricambio -11.05.0241 Descrizione del ricambio Quantità - 1 Queste informazioni ci consentiranno di fornire il corretto ricambio nel minor tempo possibile.

Avviso: Per ordinare ricambi del motore, è stata inclusa in questo manuale una lista delle parti di ricambio.

Tipo di macchina

Numero di serie Numero del della macchina disegno

Dettagli della macchina Numero della posizione

Numero del ricambio

Indirizzo

Descrizione del ricambio

Dettagli del manuale

Data

Quantità

8.2

Nome

Modulo d’ordine ricambi

CAPITOLO 8: RICAMBI

MODULO D’ORDINE RICAMBI

I 010303/01

KAPITEL 8: RESERVDELAR

S 010303/01

8.1 RESERVDELAR OCH RESERVDELSBESTÄLLNING

För en korrekt och friktionsfri reservdelsbeställning behöver vi: · Maskinens serienummer · Ritnings- och positionsnummer · Komponentnummer · Komponentbeteckning · Beställt antal EXEMPEL: BESTÄLLNING Maskinens serienummer Ritningsnummer –8.3.4 Positionsnummer -29 Komponentnummer – 11.05.0241 Komponentbeteckning Beställt antal - 1 Först nu är det möjligt för oss att så fort som möjligt leverera rätt del till dig.

ANVISNING: För beställning av reservdelar till motorn bifogar vi motortillverkarens reservdelslista

Anläggningstyp Seriennummer

Information om maskinen

Ritningsnummer

Positionsnummer

Komponentnummer Komponentbeteckning

Information om instruktionsboken

Underskrift

Datum

Beställt antal

8.2

Namn

Beställningsblankett

KAPITEL 8: RESERVDELAR

BESTÄLLNINGSBLANKETT

S 010303/01

SECTION 8: SPARE PARTS 8.3 SPARE PARTS INDEX 8.3.1

Chassis European Assembly

8.3.2

Chassis USA Assembly

8.3.3

Panfeeder European Assembly

8.3.4

Panfeeder Cassette Assembly

8.3.5

Panfeeder USA Assembly

8.3.6

Panfeeder Link Arm Assembly

8.3.7

Jackleg Assembly RHS European

8.3.8

Jackleg Assembly RHS USA

8.3.9

Main Telescopic European Assembly

8.3.10 Main Telescopic USA Assembly 8.3.11

Powerunit Assembly

8.3.12 Diesel Tank Assembly 8.3.13 Deutz 2012 Assembly 8.3.14

N/A

8.3.15

N/A

8.3.16

N/A

8.3.17

N/A

8.3.18 Fines Conveyor (Long Conveyor) 8.3.19 Fines Baseunit (Long Conveyor) 8.3.20 1st Element Fines (Long Conveyor) 8.3.21 2nd Element (Long Conveyor) 8.3.22 3rd Element Fines (Long Conveyor) 8.3.23 Screen Subframe Assembly 8.3.24 Screen Shaft Assembly SP-20

011003/02

SECTION 8: SPARE PARTS 8.3.25 Screen -Side Tension/End Tension Assembly 8.3.26

Screen Cascades/Cascades Assembly

8.3.27

Screenbox-PunchPlate/End Tension Assembly

8.3.28

Rhs Screen Access Ladder Assembly

8.3.29

LHS Screen Access Ladder Assembly

8.3.30

Oversize Chutes Assembly

8.3.31

Track Subframe Assembly

8.3.32

Transfer Conveyor General Assembly

8.3.33

Transfer Conveyor Head Section

8.3.34

N/A

8.3.35

Middle Grade Base Unit Support Frame Assembly

8.3.36

Middle Grade Conveyor Base Unit Assembly

8.3.37

N/A

8.3.38

N/A

8.3.39

Middle Grade Conveyor Complete Assembly (Long Conveyor)

8.3.40

1st Element Mid - Grade (Long Conveyor)

8.3.41

3rd Element Mid - Grade (Long Conveyor)

8.3.42

Oversize Conveyor Assembly

8.3.43

Oversize Conveyor First Element

8.3.44

Oversize Conveyor Second Element Assembly

8.3.45

Electrical Components

8.3.46

Hydraulic Circuit Diagram

8.3.47

Hydraulic Diagram

8.3.48

Electric Diagrams

SP-21

011003/02

SECTION 8: SPARE PARTS

8.3.49

Standard Electrical Specification

8.3.50

Desert Electrical Specification

SP-22

011003/02

.

46

21

9

3

25

10

32

13

31

41

37

15

42

46

1

42

46

47

40

33

45

18 17 7

41

46

50

36

23

27

22

34

49

44

38

45

40

6

24

40

45

20

5

19

45

40

35

2

8

CHASSIS EUROPEAN

41

26

39

41

Name:

30

43

29

883.01a

16

49

28

40

45

Figure :

11

4

14

12

ILLUSTRATION 8.3.1

Rev: A

ILLUSTRATION 8.3.1 Figure :

883.01a

Name:

CHASSIS EUROPEAN

Item

Part No

1

SEE_NOTE_4

0 SEE ELECTRIC DIAGRAM

1

2

SEE_NOTE_4

0 SEE ELECTRIC DIAGRAM

4

3

SEE_NOTE_5

0 SEE HYDRAULIC DIAGRAM

2

4

SEE_NOTE_4

0 SEE ELECTRIC DIAGRAM

1

5

380306050

0 PIN

2

6

380306110

0 PIN

2

7

380308130

0 PIN

3

8

380308150

0 PIN

2

9

380312190

0 380312190 PIN

2

10

883.01.12

2 BANK MNT PLT

2

11

883.01.16

0 DOZER PLT

1

12

883.01.08

0 BOLT ON CMBR

1

13

12.02.0017

0 DRAWBAR PIN

1

14

883.01.17

0 FLAP COVER

1

15

883.01.10A

0 LHS JACKLEG / BF SUPPORT(see illustration 8.3.7)

1

16

883.01.07A

0 RHS JACKLEG / BF SUPPORT(See Illustration 8.3.7)

1

17

883.38.02

0 MAIN HINGE COLLAR

2

18

883.38.01

0 MAIN HINGE PIN

2

19

883.01.19

0 OVERSIZE CMBR

1

20

883.01.20

0 SCREEN LIFT BOX

2

21

883.14.06

0 TRANSPORT BRACKET MG

1

22

683.01.09A

1 DIESEL TANK COMPLETE

1

23

883.01.14

1 LADDER SUPPORT

1

24

883.01.15

1 LADDER SUPPORT

1

25

883.14.05

1 MG TRANSPORT BKT MNT

1

26

883.01.01

3 CHASSIS MWA

1

27

883.14.07

1 MG TRANS BKT

1

Rev:

Rev Description

A

Qty

LONG CONVEYOR OPTION

28

26.44.20060

0 BOLT

8

29

26.44.16050

0 BOLT

4

ILLUSTRATION 8.3.1 Figure :

883.01a

Name:

CHASSIS EUROPEAN

Item

Part No

30

26.44.16040

0 BOLT

8

31

26.44.10040

0 BOLT

4

32

26.44.16050

0 BOLT

4

33

26.44.16050

0 BOLT

4

34

26.44.20060

0 BOLT

6

35

26.44.20175

0 BOLT

2

36

26.44.20110

0 BOLT

4

37

26.44.20060

0 BOLT

16

38

26.44.12040

0 BOLT

4

39

26.44.06040

0 BOLT

1

40

32.02.01020

0 FLAT WASHER

1

41

32.02.01016

0 FLAT WASHER

1

42

32.02.01010

0 FLAT WASHER

1

43

32.02.01006

0 FLAT WASHER

1

44

32.02.01012

0 FLAT WASHER

1

45

26.24.00020

0 NYLOC NUT

1

46

26.24.00016

0 NYLOC NUT

1

47

26.24.00010

0 NYLOC NUT

1

48

26.24.00006

0 NYLOC NUT

1

49

26.24.00012

0 NYLOC NUT

1

50

883.01.24

3 BANK MTG PLT

1

[REPORT END]

Rev:

Rev Description

A

Qty

.

15

11

4

47

13

41

37 25

20

12

10

9

27

24

36

35

1

42

41

47

47

46

28

34

16

40

45

17

21

7

3

22

48

41

26

6

30

46

44

39

31

45

40

33

23

40

45

5

19

18

45

40

32

2

8

CHASSIS USA

44

Name:

14

883.01B

38

Figure :

43

39

29

ILLUSTRATION 8.3.2

Rev: A

ILLUSTRATION 8.3.2 Figure :

883.01B

Name:

CHASSIS USA

Item

Part No

1

SEE_NOTE_4

0 SEE ELECTRIC DIAGRAM

1

2

14.02.0020

0 REMOTE STOP

2

3

SEE_NOTE_5

0 SEE HYDRAULIC DIAGRAM

2

4

SEE_NOTE_4

0 SEE ELECTRIC DIAGRAM

1

5

380306050

0 PIN

2

6

380306110

0 PIN

2

7

380308130

0 PIN

3

8

380308150

0 PIN

2

9

380312190

0 380312190 PIN

2

10

883.01.12

0 BANK MNT PLT

2

11

883.01.16

0 DOZER PLT

1

12

12.02.0017

0 DRAWBAR PIN

1

13

883.01.17

0 FLAP COVER

1

14

883.01.18A

0 JACKLEG LEFT USA (See Illustration 8.3.8)

1

15

883.01.05A

0 JACKLEG RIGHT USA(See Illustration 8.3.8)

1

16

883.38.02

0 MAIN HINGE COLLAR

2

17

883.38.01

0 MAIN HINGE PIN

2

18

883.01.19

0 OVERSIZE CMBR

1

19

883.01.20

0 SCREEN LIFT BOX

2

20

883.14.06

0 TRANSPORT BRACKET MG

1

21

683.01.09A

1 DIESEL TANK COMPLETE

1

22

883.01.14

1 LADDER SUPPORT

1

23

883.01.15

1 LADDER SUPPORT

1

24

883.14.05

1 MG TRANSPORT BKT MNT

1

25

883.01.01

3 CHASSIS MWA

1

26

883.14.07

1 MG TRANS BKT

1

27

26.44.06040

0 BOLT

1

28

26.44.20060

0 BOLT

16

29

26.44.12050

0 BOLT

4

Rev:

Rev Description

A

Qty

ILLUSTRATION 8.3.2 Figure :

883.01B

Name:

CHASSIS USA

Item

Part No

30

26.44.20110

0 BOLT

4

31

26.44.12040

0 BOLT

4

32

26.44.20175

0 BOLT

2

33

26.44.20060

0 BOLT

6

34

26.44.16050

0 BOLT

4

35

26.44.16050

0 BOLT

2

36

26.44.10040

0 BOLT

4

37

26.44.16040

0 BOLT

8

38

32.02.01006

0 FLAT WASHER

1

39

32.02.01012

0 FLAT WASHER

1

40

32.02.01020

0 FLAT WASHER

1

41

32.02.01016

0 FLAT WASHER

1

42

32.02.01010

0 FLAT WASHER

1

43

26.24.00006

0 NYLOC NUT

1

44

26.24.00012

0 NYLOC NUT

1

45

26.24.00020

0 NYLOC NUT

1

46

26.24.00016

0 NYLOC NUT

1

47

26.24.00010

0 NYLOC NUT

1

48

883.01.24

3 BANK MTG PLT

1

[REPORT END]

Rev:

Rev Description

A

Qty

.

13

18

37

29

40 31 37

37

40

40

22

40

8

24 3

40

32

37

26

37

14

40

4

35

33

42

37

25

39

40

23 40 37 21 27

34 20

PANFEEDER EUROPEAN

11

12

2

37

36

Name:

30

1

7

28

16

17

883.08A

9

5

6

38

Figure :

15

10

27

41

19

ILLUSTRATION 8.3.3

Rev: A

ILLUSTRATION 8.3.3 Figure :

883.08A

Name:

PANFEEDER EUROPEAN

Item

Part No

1

12.02.0025

0 HINGE

2

380308140

0 PIN

2

3

381508140

0 381508140 PIN

2

4

683.10.15

0 BACK CLAMP

1

5

20.883.08.01

0 BACK RUBBER

1

6

883.08.23

0 DOOR GUIDE

7

7

883.08.24

0 DOOR STAY

7

8

883.08.15

0 HOOD

2

9

10.28.0713

0 HYDRAULIC RAM

2

10

883.08.21

0 REAR DOOR MWA

1

11

883.08.27

0 SHIELD

1

12

883.08.20

0 SIDE DOOR MWA

6

13

883.08.11

0 TELESCOPIC BOSS

2

14

20.883.08.02

1 B/F SCREEN RUBBER

1

15

883.04.17

1 CLAMP

1

16

883.08.28

1 HOPPER EXTENSION

1

17

883.08.29

1 LHS HOPPER EXTENSION

1

18

883.08.12

1 PIN WASHER

2

19

883.08.30

1 REAR EXTENSION

1

20

883.08B

2 APRON CASSETTE(See Illustration 8.3.4)

1

21

883.08.25

2 LHS DRIVE GUARD

1

22

883.08.26

4 RHS DRIVE GUARD

1

23

883.08.18

5 FOLD DOWN SIDE-LEFT

1

24

883.08.01

3 BELTFEEDER MWA

1

25

883.08.02

3 BF TELESCOPIC

2

26

883.08.17

4 FOLDING SIDE RIGHT

1

27

26.44.16060

0 BOLT

6

28

26.44.12050

0 BOLT

4

29

26.44.12040

0 BOLT

2

Rev Description

Rev:

A

Qty

14

ILLUSTRATION 8.3.3 Figure :

883.08A

Name:

PANFEEDER EUROPEAN

Item

Part No

30

26.44.12045

0 BOLT

3

31

26.44.12040

0 BOLT

6

32

26.54.12045

0 COUNTER SUNK SOCKET HEAD

3

33

26.44.12060

0 BOLT

5

34

26.44.12040

0 BOLT

6

35

26.44.20090

0 BOLT

2

36

26.44.12040

0 BOLT

14

37

32.02.01012

0 FLAT WASHER

1

38

32.02.01016

0 FLAT WASHER

1

39

32.02.01020

0 FLAT WASHER

1

40

26.24.00012

0 NYLOC NUT

1

41

26.24.00016

0 NYLOC NUT

1

42

26.24.00020

0 NYLOC NUT

1

[REPORT END]

Rev Description

Rev:

A

Qty

.

9

58

47

25

46

54

29

49

5

15

58

39

4

27

54

45

2

16

67

57

7

13

23

30

52

11

36

54

10

12

22

44

54

37

58

50

58

43

60

56

42

35

55

17

54

59

26 28

54

51

31

53

6

34

40

24

21

38

14

1

18

67

61 62

68

63 64 65 66

PANFEEDER CASSETTE

8

54

48

Name:

20

3

58

883.08B

32

41

A 1:20

Figure :

33

DETAIL SCALE

19

ILLUSTRATION 8.3.4

Rev: B

ILLUSTRATION 8.3.4 Figure :

883.08B

Name:

PANFEEDER CASSETTE

Item

Part No

1

883.08.03

2 APRON PAN

2

SEE_NOTE_1

0 SEE BOLT DIAGRAM

4

3

883.08.08

2 ADJUSTER BLOCK

2

4

883.08.09

0 ADJUSTER SLEEVE

2

5

11.05.0226

0 BEARING

4

6

11.05.0240

0 BEARING

2

7

12.11.0058

0 BELLEVILLE WASHER

Rev:

Rev Description

B

Qty

62

56

ORIGINALLY 20 PER SIDE, INCR. TO 28 TO ALLOW MORE TRAVEL

8

883.08.32

0 CASSETTE GUARD- SHORT

4

9

883.08.31

0 CASSETTE GUARD-LONG

4

10

12.94.0001

0 PANFEEDER ROLLER

11

13.06.4215

0 FLANGE COUPLING

1

12

10.27.1025

0 GEARBOX C/W COLLAR

1

13

10.25.4220

0 MOTOR

1

28

Up to Ser. No. FRT540262 (plus the following machines FRT540268 & FRT540274)

13

10.25.5220

0 HYDRAULIC MOTOR

1

From Serial No. FRT540263 (Plus Serial No. FRT540256)

14

KEY_MET_28X16X

0 KEY

2

15

1BSW.NUT

0 PLAIN NUT

4

16

883.08.10

0 RETURN WHEEL

4

17

883.08.36

0 ROSTA CLAMP

1

18

883.08.34

1 ROSTA MNT BCKT

2

19

11.05.0241

0 TAKE UP BEARING

2

20

13.04.9380

0 TAPERLOCK BUSH

2

21

13.04.9385

0 TAPERLOCK BUSH

2

MUST BE ORDERED WITH 883.08.04, FOR CORRECT ALIGNMENT

22

883.08.47

1 TORQUE ARM SUPPORT

1

23

883.08.43

1 U/SIDE GUARD DRI END

1

24

883.08.44

1 U/SIDE GUARD DRI END

1

25

883.08.37

0 U/SIDE GUARD IDLER END

1

26

883.08.38

0 U/SIDE GUARD IDLER END

1

27

883.08.39

0 U/SIDE GUARD MIDDLE

1

ILLUSTRATION 8.3.4 Figure :

883.08B

Name:

PANFEEDER CASSETTE

Item

Part No

28

883.08.40

0 U/SIDE GUARD MIDDLE

1

29

883.08.07

1 ADJUSTER BAR

2

30

883.18.03

1 APRON RETURN ROLLER SHAFT

2

31

883.08.04

1 DRIVE SPROCKET

2

Rev:

Rev Description

B

Qty

MUST BE ORDERED WITH 13.04.9385, FOR CORRECT ALIGNMENT

32

883.18.01

2 IDLER SHAFT

1

33

883.08.05

1 IDLER SPROCKET

2

34

20.883.08.03

1 PAN SCRAPER

1

35

883.08.35

1 SCRAPER MNT

1

36

883.08.48

1 TORQUE ARM ASSY

1

37

883.08.03

2 APRON PAN

38

883.18.02

5 DRIVE SHAFT

39

883.08.06

40

13.10.0227

0 ROSTA TENSIONER

2

41

26.44.12080

0 BOLT

2

42

26.44.16070

0 BOLT

8

12 APRON CASSETTE MWA

62 1 1

4 PER BEARING

43

26.44.20060

0 BOLT

5

44

26.44.12140

0 BOLT

10

45

26.50.10035

0 CAP HEAD SCREW

4

46

26.44.12060

0 BOLT

4

47

26.44.12030

0 BOLT

16

48

13.05.0064

0 NUT, BOLT, WASHER

496

8 PER APRON

49

26.44.12045

0 BOLT

16

3 OFF GUARDS 23, 24, 27, 28. 2 OFF GUARDS 25, 26

50

26.44.12050

0 BOLT

4

51

26.44.12030

0 BOLT

4

52

26.44.12065

0 BOLT

112

4 PER ROLLER

53

26.44.12060

0 BOLT

4

54

32.02.01012

0 FLAT WASHER

184

55

32.02.01016

0 FLAT WASHER

16

ILLUSTRATION 8.3.4 Figure :

883.08B

Name:

PANFEEDER CASSETTE

Item

Part No

56

32.02.01020

0 FLAT WASHER

57

32.04.01010

0 SPRING WASHER

58

26.24.00012

0 NYLOC NUT

39

59

26.24.00016

0 NYLOC NUT

8

60

26.24.00020

0 NYLOC NUT

5

61

10.01.1101

0 M/M ADAPTOR

1

62

10.12.0023

0 BONDED SEAL

1

63

88310/13

0 GREASE PIPE

2

Rev:

Rev Description

B

Qty 10 4

DRIVE DRUM

63

88310/14

0 GREASE PIPE

2

IDLER DRUM

63

88310/16

0 GREASE PIPE

2

UNDERSIDE BEARING (3378mm LONG)

63

88310/18

0 GREASE PIPE

2

UNDERSIDE BEARING (2108mm LONG)

64

10.02.1206

0 90 BLOCK ELBOW

1

65

10.03.1100

0 1/8 M/F BULKHEAD ADAPTER

1

66

31.18.02000

0 GREASE NIPPLE

1

67

12.00.1111

0 CIRCLIP

2

[REPORT END]

1

17

12

41

18

40

13

23

4

DETAIL SCALE

44

39

A 1:20

2

24

6

41 44 38 41

31

28

44

33

44 41

42 45

19

30

5

14

37

44

41

36

8 34

22

10

43 46 29 44

21

41 27 35 26

25

PANFEEDER USA

20

44

9

Name:

7

41

15

883.08C

3

32

47

Figure :

16

11

ILLUSTRATION 8.3.5

Rev: B

ILLUSTRATION 8.3.5 Figure :

883.08C

Name:

PANFEEDER USA

Item

Part No

1

12.02.0025

0 G2929 6" X 1/2" HINGE

2

883.08.45

0 U/SIDE GUARD DRIVE REAR

1

3

380308140

0 380308140 PIN

2

4

380312160

0 380312160 PIN

2

5

683.10.15

0 BACK CLAMP

1

6

20.883.08.01

0 BACK RUBBER

1

7

883.08.24

0 DOOR STAY

7

8

883.08.51

0 FRONT HOPPER EXTENSION

1

Rev:

Rev Description

B

Qty

14

UPTO SERIAL NO: FRT540348

8

883.41.05

0 RHS FLAP EXTENSION

1

FROM SERIAL NO: FRT540349

9

883.08.52

0 FRONT HOPPER EXTENSION

1

UPTO SERIAL NO: FRT540348

9

883.41.04

0 LHS FLAP EXTENSION

1

FROM SERIAL NO: FRT540349

10

883.08.15

0 HOOD

2

11

883.08.50

0 HOPPER EXTENSION END

1

UPTO SERIAL NO: FRT540348

11

883.41.03

0 REAR FLARED EXTENSION

1

FROM SERIAL NO: FRT540349

12

10.28.0713

0 HYDRAULIC RAM - CLOSED 1500/ STROKE 1320

2

13

883.08.19

0 LINK ARM MNT LHS

1

14

883.08.22

0 LINK ARM MNT RHS

1

15

883.08.49

0 LONG HOPPER SIDE EXTENSION

2

UPTO SERIAL NO:FRT540348

15

883.41.02

0 RHS FLARED EXTENSION

1

FROM SERIAL NO:FRT540349

16

883.08.21

0 REAR DOOR MWA

1

17

883.08.20

0 SIDE DOOR MWA

6

18

883.08.11

0 TELESCOPIC BOSS

2

19

20.883.08.02

1 B/F SCREEN RUBBER

1

20

883.04.17

1 RUBBER CLAMP

1

21

883.08.53

1 END EXTENSION PLT

1

22

883.08.54

1 FRONT END PLATE

1

ILLUSTRATION 8.3.5 Figure :

883.08C

Name:

PANFEEDER USA

Item

Part No

23

883.08.12

1 PIN WASHER

2

24

883.08.27

2 SHIELD

1

25

883.08B

3 APRON CASSETTE

1

26

883.08.02

3 BF TELESCOPIC

2

27

883.08.25

3 LHS DRIVE GUARD

1

28

883.08.26

4 RHS DRIVE GUARD

1

29

883.08.18

5 FOLD DOWN SIDE-LEFT

1

30

883.08.17

5 FOLDING SIDE RIGHT

1

31

883.08.01

7 BELTFEEDER MWA

1

32

26.44.12040

0 SET SCREW

4

33

26.44.16060

0 16 X 60 8.8 SET SCREW

34

26.44.20090

0 SET SCREW

2

35

26.44.12040

0 SET SCREW

6

36

26.54.12045

0 COUNTER SUNK SOCKET HEAD

3

37

26.44.12060

0 SET SCREW

5

38

26.44.12040

0 SET SCREW

6

39

26.44.12045

0 SET SCREW

3

40

26.44.12040

0 SET SCREW

2

41

32.02.01012

0 FLAT WASHER

1

42

32.02.01016

0 FLAT WASHER

1

43

32.02.01020

0 FLAT WASHER

1

44

26.24.00012

0 M12 NYLOC NUT

1

45

26.24.00016

0 M16 NYLOC NUT

1

46

26.24.00020

0 M20 NYLOC NUT

1

47

883.08.49

0 LONG HOPPER SIDE EXTENSION

1

Rev:

Rev Description

B

Qty

14

UPTO SERIAL NO: FRT540348

47

883.41.01

0 LHS FLARED EXTENSION FROM SERIAL NO: FRT540349

[REPORT END]

1

.

ILLUSTRATION 8.3.6 Figure :

883.30.04

Name:

PANFEEDER LINK ARM

Rev:

A

ILLUSTRATION 8.3.6 Figure :

883.30.04

Name:

PANFEEDER LINK ARM

Item

Part No

Description

1

883.30.04

BF LINK ARM

[REPORT END]

Rev:

A

Qty 1

ILLUSTRATION 8.3.7 Figure :

883.01.07A

Name:

JACKLEG ASSEMBLY RHS EUROPEAN

Rev:

A

ILLUSTRATION 8.3.7 Figure :

883.01.07A

Name:

JACKLEG ASSEMBLY RHS EUROPEAN

Item

Part No

1

883.01.07

3 BF TELESCOPIC/WHEEL

1

2

883.01.04

2 RUNNING WHEEL

1

3

883.01.09

1 BF STOP

1

4

883.01.11

1 JACKING LEG INNER

1

5

10.28.0711

0 HYDRAULIC RAM

1

6

380308180

0 PIN

1

7

381408150

0 381408150 PIN

1

8

381412230

0 381412230 PIN

1

9

12.15.0075

0 BALL BEARING

1

10

12.11.0001

0 SPRING

1

11

10.12.0027

0 3/4" BONDED SEAL

1

12

10.09.0018

0 3/4 MALE BLANKING PLUG

1

[REPORT END]

Rev Description

Rev:

A

Qty

Figure : JACKLEG ASSEMBLY RHS USA VERSION

883.01.05A

ILLUSTRATION 8.3.8

Name:

Rev:

A

ILLUSTRATION 8.3.8 Figure :

883.01.05A

Name:

JACKLEG ASSEMBLY RHS USA VERSION

Item

Part No

Description

1

883.01.05

LINK ARM HEEL LEFT

1

2

883.01.11

JACKING LEG INNER

1

3

10.28.0711

HYDRAULIC RAM

1

4

12.09.1002

DMP 520 RUBBERSTOP

1

5

381408150

381408150 PIN

1

6

380308180

380308180 PIN

1

7

380312160

380312160 PIN

1

8

12.15.0075

BALL BEARING

1

9

12.11.0001

SPRING

1

10

10.12.0027

3/4" BONDED SEAL

1

11

10.09.0018

3/4 MALE BLANKING PLUG

1

[REPORT END]

Rev:

A

Qty

ILLUSTRATION 8.3.9 Figure :

883.30.01A

Name:

MAIN TELESCOPICS EUROPEAN

Rev:

A

ILLUSTRATION 8.3.9 Figure :

883.30.01A

Name:

MAIN TELESCOPICS EUROPEAN

Item

Part No

1

883.30.01

2 SCREEN LIFT OUTER-EURO

1

2

883.30.02

2 SCREEN TELE INNER

2

3

10.28.0106

0 HYDRAULIC RAM

2

4

883.30.07

0 SPACER BUSH

2

5

380308110

0 PIN

2

6

380308140

0 PIN

2

7

381512170

0 PIN

2

8

32.02.01024

0 FLAT WASHER

6

9

26.44.24070

0 BOLT

2

10

26.24.00024

0 NYLOC NUT

2

[REPORT END]

Rev Description

Rev:

A

Qty

ILLUSTRATION 8.3.10 Figure :

883.30.01B

Name:

MAIN TELESCOPICS USA

Rev:

A

ILLUSTRATION 8.3.10 Figure :

883.30.01B

Name:

MAIN TELESCOPICS USA

Item

Part No

1

883.30.03

1 SCREEN LIFT OUTER-USA

1

2

883.30.02

2 SCREEN TELE INNER

2

3

10.28.0104

0 HYDRAULIC RAM

2

4

883.30.07

0 SPACER BUSH

2

5

32.02.01024

0 FLAT WASHER

6

6

26.44.24070

0 BOLT

2

7

26.24.00024

0 NYLOC NUT

2

8

380308110

0 PIN

2

9

380308140

0 PIN

2

10

381512170

0 PIN

2

[REPORT END]

Rev Description

Rev:

A

Qty

59

71

62

69

19

75

35

47

58

60

42

68

71

30

75

72

2

37

16

61

71

8

71

73

75

75

69

78

63

7

79

20

75

43

64

71

9 14

52

SEE DETAIL A

41

18

6

76

77

25

71

11

4

75

65

73

10

56

53

69

39

57

44 21

45

48

26

13

31

29

24

49 50 38

27 28

DETAIL A

51

17 3

POWERUNIT 883

22

66

70

75

Name:

1

5

70

32

71

683.17C

33

67

75

36

15

Figure :

34

46

12

40

71

54

55

ILLUSTRATION 8.3.11

Rev: A

ILLUSTRATION 8.3.11 Figure :

683.17C

Name:

POWERUNIT 883

Item

Part No

1

10.21.5102

0 SUCTION FILTER

5

2

12.02.0025

0 HINGE

8

3

14.02.0020

0 REMOTE STOP

2

4

10.35.0007

0 OIL COOLER

1

5

10.21.3403

0 RETURN FILTER (ELEMENT 10.21.3402)

2

6

SEE_NOTE_4

0 SEE ELECTRIC DIAGRAM

1

7

683.17.108

0 TWIN FUEL FILTERS MTG PLT

1

8

683.17.60

0 2012C EXHAUST MTG

1

9

683.17.107

0 PRE-FUEL FILTER MTG PLT

1

10

SEE_NOTE_3

0 SEE ENGINE DIAGRAM

1

11

683.17.71

0 883 EXHAUST FOR 2012

1

12

10.23.6652

0 FLOAT LEVEL SWITCH

1

13

683.17.31

1 AIRFILTER & COOLER INTAKE GUARD

2

14

SEE_NOTE_3

0 SEE ENGINE DIAGRAM

1

15

683.17.69

0 CLAMP

1

16

683.17.05

0 POWERUNIT ACCESS DOOR

1

17

10.16.5342

0 CTRL VALVE

1

18

683.17.73

0 DETACHABLE CMBR

1

19

683.17.13

0 ENGINE ACCESS DOOR

1

20

683.17.35

5 ENGINE MNT

1

21

SEE_NOTE_4

0 SEE ELECTRIC DIAGRAM

1

22

20.683.12.02

0 HYDRUALIC TANK RUBBER MNT

2

24

683.17.106

0 WATER CAP COVER

1

25

683.17.72

0 ROOF SUPPORT

1

26

683.17.40

0 SERVICE ACCESS DOOR RHS

1

27

10.16.5308

0 SPOOL REV.S/BOX

2

28

10.16.5384

0 CONTROL VALVE

1

29

663.17.07

0 WEBTEC MNT

4

30

683.17.04

0 WEBTEC MTG PANEL

1

Rev:

Rev Description

A

Qty

ILLUSTRATION 8.3.11 Figure :

683.17C

Name:

POWERUNIT 883

Item

Part No

31

683.17.55

1 POWER UNIT ROOF (2012C)

1

32

683.17.06

1 EXHAUST COVER

1

33

20.683.12.01

1 HYD TANK SEAL

1

34

683.12.02

1 HYDRAULIC TANK LID

1

35

683.12.01

1 HYDRAULIC TANK MWA

1

36

20.683.17.02

1 P.UNIT PROTECTIVE RUBBER

1

37

683.29.01

1 RETURN MANIFOLD ASSY

1

38

683.17.09

1 START BOX MTG PANEL

1

39

683.17.37

0 AIR OUTLET DOOR WELDED ASSY

1

40

683.17.02

3 HYDRAULIC TANK GUARD

1

41

683.17.01

7 POWER UNIT FRAME

1

42

10.09.0014

0 ½" MALE BLANKING PLUG

1

43

SEE_NOTE_3

0 SEE ENGINE DIAGRAM

1

44

000.14.01

0 BATTERY BOX

1

45

12.87.0683

0 DOCUMENT HOLDER

1

46

10.22.5010

0 FILLER CAP

1

47

10.23.5008

0 LEVEL & TEMP GAUGE

1

48

15.02.0793

0 PRE CLEANER

1

49

10.16.6115

0 FLOW DIVIDER

2

50

SEE_NOTE_4

0 SEE ELECTRIC DIAGRAM

1

51

SEE_NOTE_3

0 SEE ENGINE DIAGRAM

1

52

10.16.4583

0 SOLENOID VALVE

1

53

SEE_NOTE_4

0 SEE ELECTRIC DIAGRAM

1

54

26.44.12045

0 BOLT

4

55

26.44.12045

0 BOLT

4

56

26.44.10040

0 BOLT

2

57

26.44.08040

0 BOLT

4

58

26.44.06100

0 BOLT

4

59

26.44.12040

0 BOLT

3

Rev:

Rev Description

A

Qty

ILLUSTRATION 8.3.11 Figure :

683.17C

Name:

POWERUNIT 883

Item

Part No

60

26.44.12040

0 BOLT

4

61

26.44.12035

0 BOLT

3

62

26.44.08030

0 BOLT

4

63

26.44.12045

0 BOLT

4

64

26.44.12045

0 BOLT

4

65

26.44.12040

0 BOLT

10

66

26.44.08030

0 BOLT

8

67

26.44.10030

0 BOLT

14

68

32.02.01006

0 FLAT WASHER

1

69

32.02.01008

0 FLAT WASHER

1

70

32.02.01010

0 FLAT WASHER

1

71

32.02.01012

0 FLAT WASHER

1

72

26.24.00006

0 NYLOC NUT

1

73

26.24.00008

0 NYLOC NUT

1

74

26.24.00010

0 NYLOC NUT

1

75

26.24.00012

0 NYLOC NUT

1

76

14.77.0500

0 BATTERY ISOLATOR SWITCH

1

Rev:

Rev Description

A

Qty

FROM SERIAL NO:FRT540509 ECO1753

77

683.17.134

0 BATTERY ISOLATOR BRACKET

1

FROM SERIAL NO:FRT540509 ECO1753

78

12.17.0070

0 EXHAUST CLAMP

1

79

683.17.201

0 UNIVERSAL CONTROL BANK MTG PLATE

1

(OPTION)

[REPORT END]

Figure : DIESEL TANK

683.01.09A

ILLUSTRATION 8.3.12

Name:

Rev:

A

ILLUSTRATION 8.3.12 Figure :

683.01.09A

Name:

DIESEL TANK

Item

Part No

Description

1

12.01.0013

FUEL FILLER CAP

1

2

12.75.0005

FUEL GAUGE 72 GAL

1

3

12.01.0012

FUEL TANK

1

4

000.13.01

FUEL TANK METAL STRAP

2

5

20.000.13.01

FUEL TANK PADDING RUBBER

4

6

683.01.09

FUEL TANK MOUNTING

1

7

20.000.13.02

TANK RUBBER

2

[REPORT END]

Rev:

A

Qty

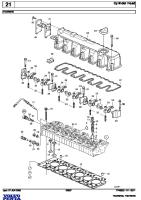

ILLUSTRATION 8.3.13 Figure :

883.17.35D

Name:

DEUTZ 2012 ENGINE

Rev:

A

ILLUSTRATION 8.3.13 Figure :

883.17.35D

Name:

DEUTZ 2012 ENGINE

Item

Part No

1

683.17.56

0 683 2012C EXHAUST PIPE 1

1

2

12.17.0056

0 EXHAUST CLAMP

2

3

683.17.112

0 FLEXI - EXHAUST PIPE

1

4

000.17.01

0 EXHAUST SILENCER BOX

1

5

683.17.57

0 EXHAUST 90 DEG BEND

1

6

15.02.0784

0 STRAINER

1

Rev:

Rev Description

A

Qty

From Sr No FRT 540313 ECO 1321

8

683.17.52

1 AIRPIPE

1

9

15.02.0089

0 AIR FILTER COMPLETE

1

10

15.02.0793

0 PRE CLEANER

1

11

15.02.0785

0 WATER TRAP

1

from Sr. No. FRT540313

12

15.02.0114

0 FILTER

1

From Sr No FRT540313

13

15.02.2022

0 BF4M2012 DEUTZ ENGIN

1

From Sr. No.FRT540313

14

000.17.03

0 THROTTLE MNT BCKT

1

15

15.02.0330

0 THROTTLE CABLE

1

16

15.02.0799

0 AIR FILTER ELEMENT

1

17

15.02.0798

0 AIR FILTER SAFETY ELEMENT

1

18

15.35.0097

0 PUMP MOUNTING PLATE

1

19

15.35.0084

0 COUPLING HUB

1

20

15.35.0072

0 FLWHEEL COUPLING FLANGE

1

21

12.14.3005

0 BATTERY

1

22

12.09.5010

0 RUBBER ENGINE MOUNT

4

23

15.02.0795

0 OIL FITER

1

24

12.17.0057

0 EXHAUST CLAMP

2

FROM SERIAL NO:FRT540337 ECO1369

25

12.17.0057

0 EXHAUST CLAMP FROM SERIAL NO:FRT540337 ECO1369

[REPORT END]

2

ILLUSTRATION 8.3.18 Figure :

883.06P

Name:

FINES CONVEYOR (LONG CONVEYOR)

Rev:

16

15

8

14 3

5 13

12

2

4

1

11 10 7

9 6

A

ILLUSTRATION 8.3.18 Figure :

883.06P

Name:

FINES CONVEYOR (LONG CONVEYOR)

Item

Part No

1

883.06V

Rev Description

0 FINES BASEUNIT (LONG CONV)

Rev:

A

Qty

1

(see illustration 8.3.19)

2

883.06S

0 1ST ELEMENT FINES (LONG CONV)

1

(see illustration 8.3.20)

3

883.06M

0 2ND ELEM FINES & MIDGRADE (LONG CONV)

1

(see illustration 8.3.21)

4

883.06.71

0 TELESCOPIC OUTER

1

TO SERIAL NO. FRT 530230

4

883.06.71

2 TELESCOPIC OUTER

1

FROM SERIAL NO. FRT 530231

5

10.28.0158

0 HYDRAULIC RAM

5

6

883.06.18

3 TELESCOPIC INNER MG

2

TO SERIAL NO. FRT 530230

6

883.06.18

5 TELESCOPIC INNER MG

2

FROM SERIAL NO. FRT 530231

7

693.30.05

0 STOPPER

4

TO SERIAL NO. FRT 530230

7

883.06.95

2 STOPPER

4

FROM SERIAL NO. FRT 530231

8

883.06N

1 3RD ELEMENT FINES (LONG CONV)

1

(see illustration 8.3.22)

9

380308110

0 PIN

2

10

380308160

0 PIN

2

11

380308120

0 PIN

9

12

380308150

0 PIN

3

13

380308130

0 PIN

2

14

380308100

0 PIN

2

15

20.03.88308

0 FINES EXTENDED BELT

1

16

20.03.88310

0 FINES CHEVRON BELT

1

OPTIONAL

[REPORT END]

45

51

53

16

53

51

35

53

55 47

51

1

44

51

3

13

50

15

39

48

14

51

21

49 51

10

53

56

53

53

32

7

43

25 9

51

53

26

51

33

42

40

17

52

24

31

54

12

30

53

27

23

34

51

6

41

29

28

5

22

2

FINES BASEUNIT (LONG CONVEYOR)

46

53

4

38

20

Name:

36

37

51

883.06V

8

51

19

Figure :

18

57

58

59

60

61

62

11

ILLUSTRATION 8.3.19

Rev: A

ILLUSTRATION 8.3.19 Figure :

883.06V

Name:

FINES BASEUNIT (LONG CONVEYOR)

Item

Part No

1

883.06.09

0 ADJUSTER RHS

1

2

883.06.10

0 ADJUSTER LHS

1

3

883.06.11

0 ADJUSTER BAR

2

4

20.883.06.01

0 BACK RUBBER

1

5

683.24.25

0 BASE RETURN CLAMP

1

6

19.22.4019

0 CENTRE ROLLER

3

7

19.30.0895

0 DISC RTN ROLLER

1

8

693.18.02

0 IDLER DRUM

1

9

20.883.06.02

0 FEEDBOOT HOPPER SIDE RUBBER

2

10

20.883.06.03

0 FEEDBOOT LINER

1

11

20.883.06.04

0 FEEDBOOT LINER

1

12

883.06.58

0 MG FRONT GUARD

1

13

883.06.24

0 PLOUGH SCRAPER MNT

1

14

883.06.25

0 PLOUGH SCRAPER MNT

1

15

883.06.34

0 REAR CLAMP

1

16

883.06.20

0 RIGHT GUARD

1

17

883.06.26

0 LEFT GUARD

1

18

883.06.27

0 REAR GUARD

1

19

883.06.50

0 REAR RUBBER CLAMP

1

20

883.06.51

0 SIDE RUBBER CLAMP

2

21

883.06.37

0 REMOVABLE CMBR

1

22

20.683.24.07

0 BASE RETURN SCRAPER

1

23

19.22.0023

0 ROLLER BASE PLT

3

24

20.883.06.05

0 SCRAPER RUBBER

1

25

693.24.09

0 SIDE CLAMP

2

26

883.06.49

0 UNDERSIDE GUARD

2

27

663.03.19

0 V-SCRAPER CLAMP

2

28

19.22.4021

0 WING ROLLER

6

29

883.06.07

1 BOLT ON CMBR

1

Rev Description

Rev:

A

Qty

ILLUSTRATION 8.3.19 Figure :

883.06V

Name:

FINES BASEUNIT (LONG CONVEYOR)

Item

Part No

30

883.06.54

1 FINES PADDLE LEFT

1

31

883.06.55

1 FINES PADDLE RIGHT

1

32

883.06.06

2 BASE UNIT MWA

1

33

883.06.12

2 MG FEEDBOOT MWA

1

34

883.06.22

2 SIDE GUARD LHS

1

35

883.06.21

2 SIDE GUARD RHS

1

36

11.02.0250

0 PILLOW BLOCK BEARING

2

37

26.44.12040

0 BOLT

4

38

26.44.12040

0 BOLT

6

39

26.44.12040

0 BOLT

12

40

26.44.12040

0 BOLT

6

41

26.44.12040

0 BOLT

4

42

26.44.16060

0 BOLT

8

43

26.44.12040

0 BOLT

6

44

26.44.12040

0 BOLT

4

45

26.44.12045

0 BOLT

8

46

26.44.12040

0 BOLT

8

47

26.44.20100

0 BOLT

4

48

26.44.12050

0 BOLT

3

49

26.44.12045

0 BOLT

12

50

26.44.12045

0 BOLT

4

51

32.02.01012

0 FLAT WASHER

1

52

32.02.01016

0 FLAT WASHER

16

53

26.24.00012

0 NYLOC NUT

1

54

26.24.00016

0 NYLOC NUT

8

55

26.24.00020

0 NYLOC NUT

4

56

30.22.00016

0 1" HEX NUT

1

57

31.18.02000

0 GREASE NIPPLE

2

58

10.03.1100

0 1/8 M/F BULKHEAD ADAPTER

2

Rev Description

Rev:

A

Qty

ILLUSTRATION 8.3.19 Figure :

883.06V

Name:

FINES BASEUNIT (LONG CONVEYOR)

Item

Part No

59

10.02.1206

0 90 BLOCK ELBOW

2

60

88310/11

0 GREASE PIPE

2

61

10.12.0023

0 BONDED SEAL

2

62

10.01.1101

0 M/M ADAPTOR

2

[REPORT END]

Rev Description

Rev:

A

Qty

ILLUSTRATION 8.3.20

13

14

11

8

5

2

1

4

10

7

Rev:

3

1ST ELEMENT FINES (LONG CONVEYOR)

12

Name:

9

883.06S

6

Figure :

A

ILLUSTRATION 8.3.20 Figure :

883.06S

Name:

1ST ELEMENT FINES (LONG CONVEYOR)

Item

Part No

1

19.22.4019

0 CENTRE ROLLER

2

2

883.06.67

0 REMOVEABLE CMBR

1

Rev Description

Rev:

A

Qty

UPTO SERIAL NO:FRT550558 ECO2118

2

883.06.67

3 REMOVEABLE CMBR

1

FROM SERIAL NO:FRT550559 ECO2118

3

19.22.0023

0 ROLLER BASE PLT

2

4

19.22.4021

0 WING ROLLER

4

5

883.06.02

7 1ST ELEMENT MWA

1

6

12.08.0002

0 8MM "U" BOLT

2

7

26.44.12040

0 BOLT

4

8

26.44.20050

0 BOLT

4

9

32.02.01008

0 FLAT WASHER

4

10

32.02.01012

0 FLAT WASHER

8

11

32.02.01020

0 FLAT WASHER

8

12

26.24.00008

0 NYLOC NUT

4

13

26.24.00012

0 NYLOC NUT

4

14

26.24.00020

0 NYLOC NUT

4

[REPORT END]

ILLUSTRATION 8.3.21 883.06M

Name:

2ND ELEMENT LONG CONVEYOR

Rev:

14

17

20

4

3

8

9

15

13

1

16

19

18

7

2

10

12

17

16

20

19

6

5

21

11

17

20

Figure :

A

ILLUSTRATION 8.3.21 Figure :

883.06M

Name:

2ND ELEMENT LONG CONVEYOR

Item

Part No

1

19.22.4019

0 CENTRE ROLLER

2

2

19.30.0895

0 DISC RTN ROLLER

1

3

19.22.0023

0 ROLLER BASE PLT

2

4

19.22.4021

0 WING ROLLER

4

5

883.06.61

1 2ND ELEMENT MWA

1

6

883.06.66

1 REMOVEABLE CMBR

1

Rev Description

Rev:

A

Qty

UPTO SERIAL NO:FRT550558 ECO2118

6

883.06.66

4 REMOVEABLE CMBR

1

FROM SERIAL NO:FRT550559 ECO2118

7

000.03.02

2 NIPGUARD-DISK 800MM

1

8

883.06.08

3 1ST ELE. REMOVABLE CMBR

1

UPTO SERIAL NO:FRT550558 ECO2118

8

883.06.08

6 1ST ELE. REMOVABLE CMBR

1

FROM SERIAL NO:FRT550559 ECO2118

9

12.08.0002

0 8MM "U" BOLT

4

10

26.44.12040

0 BOLT

8

11

26.44.20050

0 BOLT

2

12

26.44.20065

0 BOLT

4

13

26.44.12045

0 BOLT

2

14

26.44.20050

0 BOLT

4

15

32.02.01008

0 FLAT WASHER

8

16

32.02.01012

0 FLAT WASHER

1

17

32.02.01012

0 FLAT WASHER

1

18

26.24.00008

0 NYLOC NUT

8

19

26.24.00012

0 NYLOC NUT

1

20

26.24.00020

0 NYLOC NUT

1

21

12.08.0006

0 M10 'U' BOLT

2

[REPORT END]

14

7

6

15

11 25

2

39

38

44

39 3 35

34 38 43

38

9

30

8 43

43

38

22

33

13

28

42 37

18

20

45

32

41

45

43

31

38

40

38

40

17

29

36

3RD ELEMENT FINES (LONG CONVEYOR)

44

19

12

4

Name:

43

26

21

5

27

16

883.06N

10

38

24

47

49

51

Figure :

1

23

43

38

46

48

50

ILLUSTRATION 8.3.22

Rev: A

ILLUSTRATION 8.3.22 Figure :

883.06N

Name:

3RD ELEMENT FINES (LONG CONVEYOR)

Item

Part No

1

10.25.4210

Rev Description

0 HYDRAULIC MOTOR

Rev:

A

Qty

1

Up to Ser. No. FRT540262 (plus the following machines FRT540268 & FRT540274)

1

10.25.5210

0 HYDRAULIC MOTOR

1

From Serial No. FRT540263 (Plus Serial No. FRT540256)

2

532.18.01

0 DRIVE DRUM

1

3

11.05.0223

0 BEARING

2

4

19.22.4019

0 CENTRE ROLLER

1

5

883.06.65

0 CHEESE GUARD

1

6

13.06.4012

0 COUPLING

2

7

13.06.4212

0 COUPLING INSERT

1

8

20.532.03.01

0 DRIVE DRUM SCRAPER

1

9

532.03.08

0 DRIVEDRUM SCRAPER FLAT

1

10

532.03.09

0 MOTOR STAND

1

11

532.03.10

0 MOTOR STAND COUPLING GUARD

2

12

19.22.0023

0 ROLLER BASE PLT

1

13

883.06.63

0 ROSTA BRACKET

1

14

13.04.8848

0 TAPER LOCK BUSH

1

15

13.04.8854

0 TAPERLOCK BUSH

1

16

19.22.4020

0 WING ROLLER

2

17

883.06.64

1 3RD ELE. REMOVABLE CMBR

1

UPTO SERIAL NO:FRT550558 ECO2118

17

883.06.64

3 3RD ELE. REMOVABLE CMBR

1

FROM SERIAL NO:FRT550559 ECO2118

18

883.06.62

1 3RD ELEMENT MWA

1

19

770.04.18

1 CHEESE GUARD MTG

2

20

770.02.67

1 ROSTA MTG. BRACKET

1

21

770.02.68

1 ROSTA MTG. BRACKET

1

22

13.10.0227

0 ROSTA TENSIONER

2

23

26.44.12060

0 BOLT

4

24

26.44.12040

0 BOLT

4

25

26.44.16160

0 BOLT

4

26

26.44.12040

0 BOLT

4

ILLUSTRATION 8.3.22 Figure :

883.06N

Name:

3RD ELEMENT FINES (LONG CONVEYOR)

Item

Part No

27

12.08.0002

0 8MM "U" BOLT

2

28

26.44.12040

0 BOLT

4

29

26.44.20050

0 BOLT

2

30

26.44.12040

0 BOLT

4

31

26.44.12040

0 BOLT

2

32

26.44.06035

0 BOLT

4

33

26.44.12040

0 BOLT

4

34

26.44.12040

0 BOLT

4

35

26.44.16060

0 BOLT

8

36

26.44.20065

0 BOLT

4

37

32.02.01006

0 FLAT WASHER

8

38

32.02.01012

0 FLAT WASHER

1

39

32.02.01016

0 FLAT WASHER

1

40

32.02.01020

0 FLAT WASHER

1

41

32.04.01012

0 SPRING WASHER

2

42

26.24.00006

0 NYLOC NUT

4

43

26.24.00012

0 NYLOC NUT

1

44

26.24.00016

0 NYLOC NUT

1

45

26.24.00020

0 NYLOC NUT

6

46

10.12.0023

0 BONDED SEAL

2

47

10.01.1101

0 M/M ADAPTOR

2

48

88312/03

0 GREASE PIPE

1

48

88312/04

0 GREASE PIPE

1

Rev Description

Rev:

A

Qty

MOTOR SIDE

49

10.02.1206

0 90 BLOCK ELBOW

2

50

10.03.1100

0 1/8 M/F BULKHEAD ADAPTER

2

51

31.18.02000

0 GREASE NIPPLE

2

[REPORT END]

.

Long Conveyor Figure :

883.11A

Name:

SCREEN SUBFRAME

Rev:

B

Long Conveyor Figure :

883.11A

Name:

SCREEN SUBFRAME

Item

Part No

1

380312160

0 PIN

2

2

380312170

0 PIN

2

3

SEE_NOTE_5

0 SEE HYDRAULIC DIAGRAM

1

4

12.02.0017

0 DRAWBAR PIN

1

5

12.15.0610

0 CAP

10

6

12.15.6060

0 PLASTIC INSERT

10

7

20.683.11.02

0 20.15.0003 - TOP DECK CUSHION

2

8

20.883.11.01

0 20.15.0003 - TOP DECK CUSHION

2

9

683.11.07

3 FOOTWAY ASM - UPPER

2

10

883.11.01

12 SCREEN SUBFRAME MWA

1

11

883.11.02

3 CATWALK OUTRIGGER

4

12

883.11.08

3 CATWALK OUTRIGGER-LADDER MNT

1

13

883.11.10

6 FLOOR EXTN RHS

1

14

883.11.11

3 CATWALK OUTRIGGER

1

15

883.11.12

3 CATWALK OUTRIGGER

1

16

883.11.13

7 FLOOR EXTN LHS

1

17

883.11.16

4 FOOTWAY ASM - UPPER

2

18

883.11.18

1 LOWER HANDRAIL - RHS

1

19

883.11.19

2 UPPER HANDRAIL - RHS

1

20

883.11.20

3 HANDRAIL - LHS

1

21

883.11.23

0 EXTENSION HANDRAIL - LHS

1

22

883.11.24

1 CATWALK OUTRIGGER

1

23

883.14.03

0 TRANSPORT BRACKET

1

24

26.44.20070

0 BOLT

2

25

26.44.24070

0 BOLT

2

26

26.44.20070

0 BOLT

2

27

32.02.01020

0 FLAT WASHER

1

28

32.02.01024

0 FLAT WASHER

1

29

26.24.00020

0 NYLOC NUT

1

Rev:

Rev Description

B

Qty

Long Conveyor Figure :

883.11A

Name:

SCREEN SUBFRAME

Item

Part No

30

26.24.00024

[REPORT END]

Rev:

B

Rev Description

Qty

0 NYLOC NUT

1

.

19

35

38

23

41

7

26

15

13

10

34

12

14

40

2

11

33

20

39

25

42

17

45 46 47 48 49

32

37

44

31

37

43

38

SCREEN SHAFT

16

22

Name:

28

43

18

6

9

883.10A

36

4

37

3

8

24

Figure :

21

1

29

5

27

30

ILLUSTRATION 8.3.24

Rev: A

ILLUSTRATION 8.3.24 Figure :

883.10A

Name:

SCREEN SHAFT

Item

Part No

1

11.00.0150

0 BEARING

2

2

693.10.34

0 BEARING HOUSING

2

3

883.10.28

0 BOLT ON WEIGHT

4

4

12.00.1110

0 CIRCLIP

1

5

13.06.4008

0 COUPLING

2

6

13.06.4208

0 COUPLING INSERT

1

7

KEY_IMP_7_8

0 KEY

2

8

KEY_MET_14X9X5

0 KEY

1

9

10.25.3225

0 MOTOR

1

10

10.18.6033

0 O-RING

2

11

10.18.6038

0 O-RING

2

12

10.18.6076

0 OIL SEAL

2

13

10.19.0170

0 OIL SEAL

2

14

883.10.07

0 OIL SEAL RING PLATE

2

15

693.10.35

0 SEAL MOUNTING

2

16

883.10.26

0 SHAFT COVER GUARD

1

17

883.10.05

0 SHAFT HOUSING

1

18

13.04.8652

0 TAPER LOCK BUSH

1

19

883.10.19

1 BALANCE PLATE

1

20

883.10.16

1 DRIVE COVER RHS

1

21

883.10.17

1 DRIVE COVER LHS

1

22

883.10.21

1 DRIVE COVER GUARD - LHS

1

23

883.10.20

1 DRIVE COVER GUARD - RHS

1

24

883.10.35

1 MOTOR MOUNTING PLT - SAE C

1

25

883.10.06

1 SCREEN SHAFT

1

26

883.10.27

1 SCREEN WEIGHT

2

27

13.04.8608

0 TAPER LOCK BUSH

1

28

26.44.16050

0 BOLT

4

29

26.44.20120

0 BOLT

1

Rev:

Rev Description

A

Qty

ILLUSTRATION 8.3.24 Figure :

883.10A

Name:

SCREEN SHAFT

Item

Part No

30

26.44.10040

0 BOLT

4

31

26.44.20100

0 BOLT

3

32

27.52.12127

0 BOLT

14

33

26.12.08020

0 CAP HEAD BOLT

4

34

26.12.12025

0 CAP HEAD BOLT

4

35

26.44.10050

0 BOLT

8

36

32.02.01016

0 FLAT WASHER

1

37

32.02.01020

0 FLAT WASHER

1

38

32.04.01010

0 SPRING WASHER

1

39

32.04.01008

0 SPRING WASHER

1

40

32.04.01012

0 SPRING WASHER

1

41

32.02.01010

0 FLAT WASHER

1

42

26.24.00016

0 NYLOC NUT

1

43

26.24.00020

0 NYLOC NUT

1

44

27.24.00020

0 LOCK NUT

1

45

10.01.1101

0 M/M ADAPTOR

2

46

10.12.0023

0 BONDED SEAL

2

47

88310/20

0 GREASE PIPE

2

48

10.03.1100

0 1/8 M/F BULKHEAD ADAPTER

2

49

31.18.02000

0 GREASE NIPPLE

2

[REPORT END]

Rev:

Rev Description

A

Qty

.

1

35

15

4

37

12

20 18 14

34

9 30 25

27

44 42

40

31

39

44

2

42

32

24

26

23

13

21

33

10

22

SCREEN- SIDE TENSION/END TENSION

16

41

28

36

Name:

45

8

38

43

5

883.10C

6

47

49

11

19

Figure :

46

48

7

3

29

17

ILLUSTRATION 8.3.25

Rev: A

ILLUSTRATION 8.3.25 Figure :

883.10C

Name:

SCREEN- SIDE TENSION/END TENSION

Item

Part No

1

883.10.23

0 ANGLE SIDE MEMBER

2

2

683.10.15

0 BACK CLAMP

4

3

883.10.08

0 BOLT IN MEMBER

2

4

693.10.43

0 BOLT ON ANCHORS LHS

2

5

693.10.44

0 BOLT ON ANCHORS (RHS)

2

6

683.10.17

0 CAM PLATE

7

20.883.10.02

0 CUSHION RUBBER

4

8

693.10.12

0 END MESH CLAMP

6

9

883.10.13

0 FRONT STIFFENER

1

10

883.10.14

0 FRONT STIFFENER

1

11

883.10.62

0 MESH CLAMP SHORT LHS

1

12

883.10.61

0 MESH CLAMP SHORT RHS

1

13

883.10.42

0 RUBBER CLAMP

1

14

17.00.0006

0 TENSION BAR

2

15

683.10.16

0 TENSIONER UNIT

4

16

883.10.11

1 BACK STIFFENER

1

17

883.10.12

1 BACK STIFFENER

1

18

883.10.09

1 CENTRE STIFFENER

1

19

883.10.10

1 CENTRE STIFFENER

1

20

10.28.0161

1 HYDRAULIC RAM

4

21

20.883.10.10

1 MID-GRADE CHUTE BACK RUBBER

1

22

20.883.10.12

1 MID-GRADE CHUTE FRONT RUBBER

1

23

20.883.10.11

1 MID-GRADE CHUTE SIDE RUBBER

1

24

20.883.10.05

1 SCREEN SHROUD BACK RUBBER

1

25

20.883.10.06

1 SCREEN SHROUD SIDE RUBBER

1

26

20.883.10.07

1 SCREEN SHROUD SIDE RUBBER (SAME AS 20.883.10.06)

1

27

883.10A

1 SHAFT ASSY - PHANTOM

1

28

883.10.02

1 SIDE TENSION FRAME - TOP DECK

1

29

883.10.31

1 SIDE WALL MWA - LHS

1

Rev Description

Rev:

A

Qty

16

ILLUSTRATION 8.3.25 Figure :

883.10C

Name:

SCREEN- SIDE TENSION/END TENSION

Item

Part No

30

883.10.01

1 SIDE WALL MWA - RHS

1

31

883.10.04

2 END TENSION FRAME

1

32

883.10.37

2 LHS RUBBER CLAMP

1

33

20.883.10.08

2 OVERSIZE CHUTE RUBBER

1

34

883.10.36

2 RHS RUBBER CLAMP

1

35

883.10.24

3 EXTENSION FLAP

4

36

883.10.33

3 LOWER EXTENSION FLAP - LHS

1

37

883.10.32

3 LOWER EXTENSION FLAP - RHS

1

38

26.44.20060

0 BOLT

32

39

26.44.12050

0 BOLT

7

40

26.44.12050

0 BOLT

11

41

32.02.01020

0 FLAT WASHER

1

42

32.02.01012

0 FLAT WASHER

1

43

26.24.00020

0 NYLOC NUT

1

44

26.24.00012

0 NYLOC NUT

1

45

883.10.124.01

1 BALL DECK MESH

2

Rev Description

Rev:

A

Qty

ECO2078

46

883.10.125

1 END TENSION FRAME TO SUIT BALL DECK

1

ECO2078

47

694.10.55

1 BALLDECK MESH CLAMP

10

ECO2078

48

694.10.50

1 BALLDECK BOLT ON MBR

6

ECO2078

49

12.61.0001

0 50MM AGGITATOR BALLS ECO2078

[REPORT END]

120

.

1

34

18

11

29 36 53 7 49 48

24

38

33 25

26

2

39

23 46 51

31

55

47

4

10

40

6

22

55

17 51

16

55

58

19 28

51

45

41

35

55

32

42

58

51

51

8

44

55 43

21

20

51

SCREEN- CASCADES & BOFOR BARS

37

50

30

56

Name:

58

54

14

58

57

883.10E

15

52

9

13

59

Figure :

5

12

3

27

61

60

ILLUSTRATION 8.3.26

Rev: A

ILLUSTRATION 8.3.26 Figure :

883.10E

Name:

SCREEN- CASCADES & BOFOR BARS

Item

Part No

1

883.10.23

0 ANGLE SIDE MEMBER

2

2

683.10.15

0 BACK CLAMP

4

3

883.10.08

0 BOLT IN MEMBER

2

4

883.10.57

0 BTM DECK CASCADE FRAME

1

5

693.33.33

0 CASCADE SHIM

6

883.10.30

0 FRONT DIAGONAL MEMBER

1

7

883.10.13

0 FRONT STIFFENER

1

8

883.10.14

0 FRONT STIFFENER

1

9

883.10.29

0 REAR DIAGONAL MEMBER

1

10

883.10.42

0 RUBBER CLAMP

1

11

883.10.15

0 SCREEN MOUNT

4

12

693.33.15

0 SCREENBOX CASCADE

Rev Description

Rev:

A

Qty

23

12

TO SERIAL NO. FRT 530174

13

12.90.7960

0 PILOT TINE

1

14

883.10.81

1 T.D. CASCADE FRAME - 55MM

1

TYNES NOT INCLUDED (FROM SERIAL NO. FWT530070)

14

883.10.83

1 1ST T. D CASCADE FRAME - 65MM

1

TYNES NOT INCLUDED (FROM SERIAL NO. FWT530070)

14

883.10.85

1 1ST T.D. CASCADE FRAME - 75MM

1

TYNES NOT INCLUDED (FROM SERIAL NO. FWT530070)

14

883.10.87

1 1ST T.D CASCADE FRAME - 100MM

1

TYNES NOT INCLUDED (FROM SERIAL NO. FWT530070)

14

883.10.89

1 1ST T.D. CASCADE FRAME - 125MM

1

TYNES NOT INCLUDED (FROM SERIAL NO. FWT530070)

14

883.10.91

1 1ST T.D. CASCADE FRAME - 150MM

1

TYNES NOT INCLUDED (FROM SERIAL NO. FWT530070)

15

883.10.11

1 BACK STIFFENER

1

16

883.10.12

1 BACK STIFFENER

1

17

883.10.43

2 CASCADE TOP DISCHARGE PLT MWA

1

18

883.10.09

1 CENTRE STIFFENER

1

19

883.10.10

1 CENTRE STIFFENER

1

20

20.883.10.10

1 MID-GRADE CHUTE BACK RUBBER

1

21

20.883.10.12

1 MID-GRADE CHUTE FRONT RUBBER

1

22

20.883.10.11

1 MID-GRADE CHUTE SIDE RUBBER

1

ILLUSTRATION 8.3.26 Figure :

883.10E

Name:

SCREEN- CASCADES & BOFOR BARS

Item

Part No

23

20.883.10.05

1 SCREEN SHROUD BACK RUBBER

1

24

20.883.10.06

1 SCREEN SHROUD SIDE RUBBER

1

25

20.883.10.07

1 SCREEN SHROUD SIDE RUBBER (SAME AS 20.883.10.06)

1

26

883.10A

2 SHAFT ASSY (See Illustration 8.3.19)

1

27

883.10.47

2 SHIM

28

883.10.31

1 SIDE WALL MWA - LHS

1

29

883.10.01

1 SIDE WALL MWA - RHS

1

30

883.10.80

1 TINE LOCATING BOX-55MM APERTURE

6

Rev Description

Rev:

A

Qty

14

TYNES NOT INCLUDED (FROM SERIAL NO. FWT530070)

30

883.10.82

1 TINE LOCATING BOX-65MM APERTURE

6

TYNES NOT INCLUDED (FROM SERIAL NO. FWT530070)

30

883.10.84

1 TINE LOCATING BOX-75MM APERTURE

6