TMHydraulicSystemFLT.01en ECH FLT Hydraulic [PDF]

TECHNICAL MANUAL FORKLIFT HYDRAULICS ORIGINAL INSTRUCTIONS X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en Thi

29 0 1MB

Papiere empfehlen

![TMHydraulicSystemFLT.01en ECH FLT Hydraulic [PDF]](https://vdoc.tips/img/200x200/tmhydraulicsystemflt01en-ech-flt-hydraulic.jpg)

- Author / Uploaded

- Ngoc Nguyen

Datei wird geladen, bitte warten...

Zitiervorschau

TECHNICAL MANUAL FORKLIFT HYDRAULICS

ORIGINAL INSTRUCTIONS X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en This document and the information contained herein, is the exclusive property of Konecranes Lifttrucks and represents a non-public, confidential and proprietary trade secret that may not be reproduced, disclosed to other parties, altered or otherwise employed in any manner whatsoever without the express written consent of Konecranes Lifttrucks. © 2014 Konecranes Lifttrucks. All rights reserved. ‘Konecranes’, ‘Lifting Businesses’ and C are either registered trademarks or trademarks of Konecranes Lifttrucks.

TABLE OF CONTENTS

TECHNICAL MANUAL

TABLE OF CONTENTS 1 1.1

DESCRIPTION.......................................................................................................... Load-sensing system.............................................................................................. 1.1.1 Description................................................................................................... 1.1.2 Function....................................................................................................... Location of components..........................................................................................

5 5 5 6 8

COMPONENTS DESCRIPTION................................................................................ Variable piston pump............................................................................................... 2.1.1 Parker series P2.......................................................................................... 2.1.2 Function....................................................................................................... Load-sensing system.............................................................................................. Steering priority valve............................................................................................. Directional control valve.......................................................................................... 2.4.1 Parker L90LS............................................................................................... 2.4.2 Parker HV08................................................................................................ Accumulator charging valve................................................................................... 2.5.1 M0382.......................................................................................................... 2.5.2 M1040.......................................................................................................... Hydraulic system principle (Forklift SMV 10-16B)................................................. Hydraulic system principle with M1040 (Forklift SMV 10-16B).............................

9 9 9 10 12 14 17 17 18 20 20 21 23 25

3.6 3.7 3.8 3.9 3.10 3.11 3.12 3.13 3.14 3.15 3.16 3.17

MEASUREMENTS AND ADJUSTMENTS................................................................ Measuring and setting the hydraulic pressure...................................................... Measuring and setting the stand-by pressure, one pump.................................... 3.2.1 Checking the load signal (LS)...................................................................... 3.2.2 Adjusting the stand-by pressure................................................................... Measuring and setting the stand-by pressure, multiple pumps........................... Measuring and setting the maximum working pressure....................................... Measuring and setting the delta pressure (DeltaP)............................................... 3.5.1 Principle....................................................................................................... 3.5.2 Measuring and setting the delta pressure, one pump................................... 3.5.3 Measuring and setting the delta pressure, two or three pumps.................... Releasing the accumulator pressure...................................................................... Measuring and setting the accumulator pressure................................................. Measuring and setting the brake pressure switch................................................. Measuring the accumulator precharged pressure................................................. Measuring and setting the parking brake pressure............................................... Adjusting the parking brake.................................................................................... Measuring the steering pressure............................................................................ Adjusting the steering priority valve (older machines only)................................. Adjusting steering priority valve (new machines only)......................................... Setting the restrictor and non-return valve............................................................ Measuring and adjusting the attachment pressure (ECB).................................... Measuring and adjusting the attachment pressure (gantry).................................

27 27 27 27 28 28 29 29 29 30 31 32 33 34 34 34 35 36 36 36 38 38 39

4 4.1

TROUBLESHOOTING............................................................................................... 41 ................................................................................................................................... 0

1.2 2 2.1

2.2 2.3 2.4

2.5

2.6 2.7 3 3.1 3.2

3.3 3.4 3.5

3/42 This document and the information contained herein, is the exclusive property of Konecranes Lifttrucks and represents a non-public, confidential and proprietary trade secret that may not be reproduced, disclosed to other parties, altered or otherwise employed in any manner whatsoever without the express written consent of Konecranes Lifttrucks. © 2014 Konecranes Lifttrucks. All rights reserved. ‘Konecranes’, ‘Lifting Businesses’ and C are either registered trademarks or trademarks of Konecranes Lifttrucks.

TECHNICAL MANUAL

TABLE OF CONTENTS

4/42 This document and the information contained herein, is the exclusive property of Konecranes Lifttrucks and represents a non-public, confidential and proprietary trade secret that may not be reproduced, disclosed to other parties, altered or otherwise employed in any manner whatsoever without the express written consent of Konecranes Lifttrucks. © 2014 Konecranes Lifttrucks. All rights reserved. ‘Konecranes’, ‘Lifting Businesses’ and C are either registered trademarks or trademarks of Konecranes Lifttrucks.

TECHNICAL MANUAL

1 DESCRIPTION

1

DESCRIPTION

1.1

Load-sensing system

1.1.1

Description In a load-sensing hydraulic system, the pump only supplies the flow which required for the functions. The output of the pump is never greater than the current load. All Konecranes Lifttruck hydraulic systems are load-sensing. Load

Pump

The load-sensing system has the following advantages: • • • • • • •

No flow in the system when it is not used Only the required flow when lifting or moving No unnecessary overpressure when lifting small loads Smaller losses and less wear to the hydraulic system Greater precision and more flexible maneuvering of the machine Lower energy consumption Less heat development

In a load-sensing system, the load to which the system is subjected measures and controls the output from the hydraulic pump. The system remains in balance: • Light load - low output • Heavy load - high output Pump

Load

The variable piston pump is the main component of the system. When the load on the system changes, for example, when lifting, a signal provides the pump with information about the change. The system makes a corresponding change to the output. Pump

Load Load signal

The following diagram shows the principle of a load-sensing system. The load signal (LS) which controls the pump is taken from the directional control valve. 5/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

1 DESCRIPTION

Pump

Load

LS Directional valve

1.1.2

Function Use a joystick to control the hydraulic functions which actuate the directional control valve. The system is proportional. A small joystick movement gives a small deflection on the directional control valve, for little oil flow, and a large joystick movement gives a larger deflection on the valve, for large oil flow.

When the directional control valve is closed, the pump gives a low basic pressure, called standby pressure. When the system is activated, oil flows through the directional control valve, from P to A, and the pressure drops. This pressure drop is called DeltaP. A

LS

P

T

6/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

1 DESCRIPTION

Make sure that the stand-by pressure is slightly higher than DeltaP. It is important that the pump provides the correct stand-by pressure in order for the system to work correctly. When the joystick is in the neutral position and the system is not at work, the load signal is zero. The output from the pump, which corresponds to the stand-by pressure, is low, and the output requirement from the diesel engine is also low.

A small joystick movement only causes a small flow, yet high pressure. The load signal provides the pump with information, and the pump then gives the corresponding output.

45

A large joystick movement causes a large flow and high pressure. The load signal provides the pump with information, and the pump then gives the maximum output.

45

7/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

1.2

1 DESCRIPTION

Location of components

8

9

7

6

10

5 11 4

12

3 13

14

2 1

Figure 1. Forklift SMV 10-16B 1. 2. 3. 4. 5. 6. 7.

Steer cylinder Variable piston pump (105 cc) Gear pump (23 cc) Accumulator Steering orbitrol Tilt cylinder Lift cylinder

8. 9. 10. 11. 12. 13. 14.

Side shift cylinder Directional control valve Multi-disc brake Parking brake Steering priority valve Accumulator charging valve Hydraulic tank

8/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2 COMPONENTS DESCRIPTION

2

COMPONENTS DESCRIPTION

2.1

Variable piston pump

2.1.1

Parker series P2 2

3

5

4

1

7

4

6

8

5

1

6

11

9

10

Figure 2. Variable piston pump 1. 2. 3. 4. 5. 6.

Input shaft Adjusting screw (DeltaP) Adjusting screw (P-max) Adjusting screw (displacement) Outlet Inlet

7. 8. 9. 10. 11.

Servo piston Swashplate Pump housing Piston Barrel

9/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2.1.2

2 COMPONENTS DESCRIPTION

Function

V2

A

V1

The input shaft rotates and drives the barrel and pistons. Oil is drawn into the cylinders through the inlet side and is pressed out of the cylinders through the outlet side. The angle of the swashplate (A) determines the volumes (V1) and (V2). The difference between (V1) and (V2) is the displacement, the volume of oil the pump gives per revolution. When the actuator pressure is zero, the swashplate (A) tilts to maximum. The difference in volume on the inlet side (V1) and outlet side (V2) is at its most and the pump supplies its maximum flow. When the load signal is zero, the actuator pressure holds back the swashplate tilts to minimum and there is no flow.

V2

A

V1

When less oil is required, the angle (A) of the swashplate is reduced. The difference between (V1) and (V2) drops and the pump supplies a smaller quantity of oil.

10/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2 COMPONENTS DESCRIPTION

V2

A

V1

With minimal oil requirement, the angle (A) of the swashplate is virtually zero and the difference between (V1) and (V2) is at its least and the pump supplies a small oil flow.

11/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2.2

2 COMPONENTS DESCRIPTION

Load-sensing system The following illustration shows the engine switched off on the left and the engine running on the right. When there is no pressure in the system, the spring-loaded actuator piston (1) of the pump is in the position for maximum pump output. The line from the spring-loaded actuator piston (1) runs through the valve for maximum pressure (P-max) and stand-by pressure valve (DeltaP) directly to the hydraulic tank. Adjust the pressure in the DeltaP using an Allan key. A B

A

Directional valve

LS

P

B

Directional valve

LS

P 2

DeltaP

DeltaP

Pmax

Pmax

1

Pump

Pump

When the diesel engine starts, the pump gives maximum output for a short period until the stand-by pressure is reached. Once the stand-by pressure is reached, the valve (2) adjusts the pump and maintains at the set pressure irrespective of the speed of the diesel engine.

12/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2 COMPONENTS DESCRIPTION

A

B

AB

3

Directional valve

LS

Directional valve

LS

P

P 6

4

DeltaP

Pmax

DeltaP

Pmax

5

Pump Pump

When the system is put to work through the joystick, the directional control valve (3) changes position and the (LS) line is pressurized. The valve (4) is reset and the pressure in the actuator piston (5) drops. The pump output then increases until it corresponds with the load on the system. When the pump output corresponds to the load on the system, the valve (6) is adjusted and maintains the pump at the right output.

13/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2 COMPONENTS DESCRIPTION

A

B

A

3

B

Directional valve

LS

P

Directional valve

LS

P

4

DeltaP

DeltaP

Pmax

5

7

Pmax

8

Pump

Pump

When the cylinder is at the end position, the pressure can reach maximum. The pressure in the load signal (LS) increases and the valve (4) is reset. The pressure in the actuator piston (5) decreases and the pump output increases. When the pump output is equal to the set maximum pressure for the valve (7) its position changes. The pressure in the actuator piston (8) increases and the pump output decreases. The pressure is maintained until the cylinder moves or the directional control valve switches.

2.3

Steering priority valve The steering priority valve is preset to give a controlled pressure of 180 ... 200 bar.

14/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2 COMPONENTS DESCRIPTION

PP

5 4 EF 6 3

P

CF

LS

2

1

R 1. Pressure regulator 2. Load Sensor (LS) - load signal from steering orbitrol 3. Excess Flow (EF) to directional control valve

4. Controlled Flow (CF) to steering orbitrol 5. External pilot signal (PP) 6. From the piston pump (P)

15/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2 COMPONENTS DESCRIPTION

3

2 4

5 6

7

8 1 Figure 3. Hydraulic system - steering principle 1. 2. 3. 4.

Steer cylinder Steering orbitrol Steering priority valve Pressure regulator

5. 6. 7. 8.

Shuttle valve Restrictor and non-return valve Variable piston pump (105 cc) Hydraulic tank

Oil leads from the variable piston pump (7) (105 cc) to the steering priority valve (3). The main function of the steering priority valve (3) is to supply oil to the steering system ahead of the machine's other hydraulic functions. When the engine starts, the pressure builds up to stand-by pressure. The steering priority valve (3) receives stand-by pressure at port P from the pump. The stand-by pressure is transferred to CF and further to the steering orbitrol (2). Return pressure at the steering orbitrol feeds to PP on the priority valve. The valve switches position so that the stand-by pressure is on EF, to which the directional control valve is connected. The steering orbitrol feeds a small contracted oil flow through the LS-line into the tank.

16/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2 COMPONENTS DESCRIPTION

When the steering orbitrol is activated during steering, the pressure on PP drops and the priority valve switches position again and oil flows from the pump through the priority valve P to CF, the steering orbitrol P to the steer cylinder. The adjustable pressure regulator (4) opens at maximum steering pressure (steering to end position).

2.4

Directional control valve

2.4.1

Parker L90LS 6

4

5

3

10

7

2 11 12

8 1

9 Figure 4. Directional control valve - Parker L90LS 1. 2. 3. 4. 5. 6.

Pilot circuit for joysticks (PS) Tank connection for pilot circuit (TPB) Hydraulic function (B) Hydraulic function (A) Connections from control joysticks Control for emergency lowering (forklift)

7. 8. 9. 10. 11. 12.

Pump connection (P1) Tank connection (T1) Electrically controlled proportional valve Load signal connection (LS), copied Pump pressure (PX) Load signal connection (PL), non-copied 17/42

X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2 COMPONENTS DESCRIPTION

2

3

8

1

7

5

6

4

Figure 5. Schematic - Parker L90LS 1. Valve for maximum pressure 2. Copy spool - copies the load signal from hydraulic function to the pump 3. Pressure limiter on load signal - used for extra functions, for example, joystick steering 4. Pressure regulator for pilot pressure

2.4.2

5. Shuttle - gives priority to highest load signal 6. Compensator valve - limits the highest permitted pressure for the circuit 7. Non-return valve 8. Maneuver spool

Parker HV08 3

1

2

Figure 6. Directional control valve - Parker HV08 1. Function section 2. Pump connection (P)

3. Tank connection (T)

18/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2 COMPONENTS DESCRIPTION

A

B

1 b a B A

a B A

b a

B A

3 b a

T2

P2 P1

T1B T2

T1

AB TGA LD

AB

TGA

LSU

LSIB

LSU

LSIB

P

P

10

9

8

7

6

2

5

4

Figure 7. Schematic - Parker HV08 A

2 spool sections

B

1 spool section

1. 2. 3. 4. 5.

Pressure balance point A-B port Pump connection spool section (P1) Tank connection (T2) Load signal connection (LSU) Load signal, drainage

6. 7. 8. 9. 10.

Section spool Plug copy spool Copy spool Non-return valve Pump connection (P)

19/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2 COMPONENTS DESCRIPTION

2.5

Accumulator charging valve

2.5.1

M0382 1 3

5

6

2

8 4

3

7

4

PRM

ACC T2 ACCM ACC1 5

2

6 PM

1 PB

T

P 8

7

Figure 8. Accumulator charging valve - M0382 1. 2. 3. 4. 5.

Parking brake solenoid Pressure regulator for parking brake Pressure discharge of accumulator Pressure limiting valve (280 bar) Non-return valve

6. Restrictor 7. Charge valve 8. Pressure regulator for accumulator charging

20/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2 COMPONENTS DESCRIPTION

2.5.2

M1040 6

5

1 2

9

8

3 4

7

2

8

3

4

PRM

ACC T2

ACCM

5

ACC1

2 6 PM

1

9

PB

T

P

8

7

Figure 9. Accumulator charging valve - M1040 1. 2. 3. 4. 5.

Parking brake solenoid Pressure regulator for parking brake Pressure discharge of accumulator Pressure limiting valve (280 bar) Non-return valve

6. Restrictor 7. Charge valve 8. Pressure regulator for accumulator charging 9. Pressure limiting valve (210 bar)

The accumulator charging valve receives oil from the gear pump. Oil is distributed in the valve to the accumulator, service brake, parking brake. If there is an engine failure, these functions receive oil from the accumulator through the accumulator charging valve.

21/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2 COMPONENTS DESCRIPTION

Item No.

Components

Functions

1

Parking brake solenoid

For parking brake. Electrically controlled valve to activate the parking brake. When the valve is not activated, the parking brake is employed.

2

Pressure regulator for parking brake

For the parking brake circuit. Reduces the pressure from the accumulator to the parking brake circuit.

3

Pressure discharge of accumulator

For pressure release. The accumulator is drained manually using a hex key. Used BEFORE working on the hydraulic system.

4

Pressure limiting valve

For maximum pressure preset to 250 bar. Prevents excess charging of the accumulator.

5

Non-return valve

The non-return valve prevents the accumulator from being discharged when the engine is switched off. It is located between the pump and accumulator or service brake.

6

Restrictor

Restricts the pressure in the circuit.

7

Charge valve

Regulates the pressure to the accumulator circuit. Controlled by the pressure regulator (8).

8

Pressure regulator for accumulator charging

For the accumulator. Measures the pressure in the accumulator circuit and controls the valve (7). Accumulator charging starts when the pressure is 20% below the set pressure.

22/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2 COMPONENTS DESCRIPTION

2.6

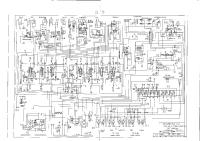

Hydraulic system principle (Forklift SMV 10-16B) 15 14

16

11

17

12

6 13 10 4

9

5 8

7

2 1

4 3

Figure 10. Schematic - hydraulic system 23/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

1. 2. 3. 4. 5. 6. 7. 8. 9.

Hydraulic tank Gear pump (23 cc) Variable piston pump (105 cc) Restrictor and non-return valve Shuttle valve Steering priority valve Steer cylinder Steering orbitrol Parking brake

2 COMPONENTS DESCRIPTION

10. 11. 12. 13. 14. 15. 16. 17.

Multi-disc brake Service brake valve Accumulator Accumulator charging valve Return filter Hydraulic functions Directional control valve (L90) Control joysticks

24/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

2 COMPONENTS DESCRIPTION

2.7

Hydraulic system principle with M1040 (Forklift SMV 10-16B)

15

14

B A

B A

B

B

A

A

B

PS

A

T1

Tp P2

P1 LS

LSPB

16

11

17

P T

12

BR

T

BL

BM P PRM

ACC

T2 ACCM ACC1

13

PM

10

PB

T

PP

P

EF CF LS

4

9

6

P

T

5

8 7

R

P

L

LS T

4 3

2 1 Figure 11. Schematic - hydraulic system 1. 2. 3. 4.

Hydraulic tank Gear pump (23 cc) Variable piston pump (105 cc) Restrictor and non-return valve

5. 6. 7. 8.

Shuttle valve Steering priority valve Steer cylinder Steering orbitrol 25/42

X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

9. 10. 11. 12. 13.

Parking brake Multi-disc brake Service brake valve Accumulator Accumulator charging valve (M1040)

2 COMPONENTS DESCRIPTION

14. 15. 16. 17.

Return filter Hydraulic functions Directional control valve (L90) Control joysticks

A gear pump (2) (23 cc) supplies oil to the accumulator charging valve (13) from the hydraulic tank (1). The pressure is distributed in the valve to the accumulator (12), service brake (11), and the parking brake (9). Oil from the valve also cools the multi-disc brake (10) in the drive axle. The gear pump is seated in tandem on the variable piston pump (3) (Parker series P2, 105 cc). Oil from the piston pump goes to the steering priority valve (6) which distributes the oil to the steering orbitrol (8) and the directional control valve (16) (Parker L90). The priority valve ensures that the steering is given priority over the other functions of the machine. The load signal leads back from the steering orbitrol to the priority valve and to the shuttle valve (5) where it is compared to the load signal from the directional control valve. After the shuttle valve, the load signal leads through a restrictor and non-return valve (4) to the piston pump. Control the directional control valve with the control joysticks in the cab, distributing oil to respective hydraulic functions (15). The return oil from the functions runs through the directional control valve back to the hydraulic tank where the return filter (14) is located.

26/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

3 MEASUREMENTS AND ADJUSTMENTS

3

MEASUREMENTS AND ADJUSTMENTS

3.1

Measuring and setting the hydraulic pressure Location of the measuring point and adjustment points differ slightly on the different machine models. For pressure values not stated in this manual, see the machine card.

3.2

Measuring and setting the stand-by pressure, one pump The correct stand-by pressure is a prerequisite for hydraulic functions to work properly. The pressure is measured when the hydraulic system is not working (load signal is zero) and the diesel engine is in the idle position.

3.2.1

Checking the load signal (LS) 1. Connect a pressure gauge (300 bar) to the test point (1).

1

2. Start the diesel engine and let it idle. 3. Check that the pump load signal is zero bar, the hydraulics not in use. 4. Perform the troubleshooting action if the load signal (LS) is not at zero bar. For more information, see Troubleshooting (page 41).

NOTE

If the load signal (LS) is not at zero bar, then the stand-by pressure cannot be set correctly.

27/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

3.2.2

3 MEASUREMENTS AND ADJUSTMENTS

Adjusting the stand-by pressure 1. Connect a pressure gauge (300 bar) to the test point (2) at the pump outlet.

3

2 2. Start the diesel engine and let it idle. The pressure rises to 33 bar. 3. If necessary, adjust the stand-by pressure using set screw (3) on the pump marked 'Delta P'.

3.3

Measuring and setting the stand-by pressure, multiple pumps 1. Check that the load signal (LS) is at zero bar. For more information, see Measuring and setting the stand-by pressure, one pump (page 27).

NOTE

Always start with the lowest stand-by pressure pump and then adjust the other pumps in ascending order of pressure. 2. Connect a pressure gauge (300 bar) to the test point for outgoing pressure from the pumps. 3. To adjust the pressure, use the upper set screw (4) marked 'Delta P' on the pump.

4

4. Unscrew the set screw on all pumps to approximately 15 bar. 5. Measure the pressure on the relevant pump. 6. To set the pressure as per the data on the machine card, use the set screw (4) on each pump. 28/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

3 MEASUREMENTS AND ADJUSTMENTS

3.4

Measuring and setting the maximum working pressure When using a hydraulic function, the working pressure rises to the level required to carry out the work. Maximum pressure is only reached at maximum work load or when a hydraulic function reaches its end position. 1. Connect a pressure gauge (300 bar) to the measuring point (1). To achieve maximum operating pressure, lift the mast to maximum height.

2

1 2. To set the pressure of all pumps, screw out the adjusting screw P-max (2) by approximately one turn. The maximum pressure is set with the lower adjusting screw (P-max) on the pumps.

NOTE

To adjust the pressure of a single pump, reduce the pressure of the other pumps.

NOTE

Adjust the maximum operating pressure of the pump according to increase in pressure order. 3. To check that the pump is operating properly, set the pressure 10 bar above the maximum pressure. After this check, set the pressure according to the machine card.

3.5

Measuring and setting the delta pressure (DeltaP)

3.5.1

Principle A pressure drop occurs (DeltaP) when oil flows through the directional control valve. If DeltaP is too low, the pump does not provide sufficient oil flow which results in the incorrect working of the hydraulic system.

29/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

3 MEASUREMENTS AND ADJUSTMENTS

LS

P1

A symptom of DeltaP being too low is that the hydraulic system normally works with a low speed of the diesel engine while at a high speed the system works slowly or not at all. Too-high DeltaP results in the hydraulic functions being difficult to control and that the other advantages of the load-sensing system decreases.

NOTE

3.5.2

The measuring and setting procedure differs for machines equipped with one variable pump or several variable pumps.

Measuring and setting the delta pressure, one pump 1. Connect a pressure gauge to the measuring point (1) on the outlet of the pump and to the measuring point (2) on the LS-line. 2

3

1 2. Start the diesel engine and run at 1000 ... 1500 rpm. 3. To run a hydraulic function without a load, but not to the end position, move the joystick halfway. 4. Read the pressure difference while the function is running. The pressure difference is DeltaP. 5. If necessary, adjust the delta pressure with the adjusting screw (3) marked Delta P on the pump.

30/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

3 MEASUREMENTS AND ADJUSTMENTS

3.5.3

Measuring and setting the delta pressure, two or three pumps When measuring the delta pressure on one of the variable pumps, disconnect and plug the LSlines to the other variable pumps. Drain the LS-outlet on the pumps to the tank through extra hydraulic hoses connected to the LS-outlet and routed to the hydraulic tank.

NOTE

The following procedure is for one pump. Repeat the procedure to measure the other pumps. 1. Connect a pressure gauge to the measuring point (1) of the LS-line.

3 1

2

3

2

2. Remove the LS-lines from the other pumps and plug the lines (2). 3. Connect extra hoses to the LS-outlets (3). 4. Remove the breathing filters and position the hoses in the hydraulic tank (4).

4

31/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

3 MEASUREMENTS AND ADJUSTMENTS

5. Connect the other connection from the pressure gauge to the measuring point (5) on the pump to be measured.

5 6. Start the diesel engine and run at 1000 ... 1500 rpm. 7. To run a hydraulic function without a load, but not to the end position, move the joystick halfway. 8. Read the pressure difference while the function is running. The difference is DeltaP. 9. If necessary, adjust the delta pressure with the adjusting screw (6) marked Delta P on the pump. 6

3.6

Releasing the accumulator pressure The accumulator is normally at high pressure. Discharge the pressure in the accumulator before working on the hydraulic system of the machine.

32/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

3 MEASUREMENTS AND ADJUSTMENTS

1. To loosen the locknut, use a box wrench.

2. To relieve the pressure, loosen the Allen screw.

3.7

Measuring and setting the accumulator pressure 1. Connect a pressure gauge (300 bar) to the measuring point (1) marked ACCM on the accumulator charging valve.

3 2 1 4 2. Start the diesel engine and let it idle. 3. Press the service brake repeatedly. The pressure drops. The diesel engine audibly starts to work and the charging cycle of the accumulator starts. 4. When the load on the diesel engine decreases, the charging cycle of accumulator ends. Record the pressure. 5. If necessary, adjust the accumulator pressure setting on the adjusting screw (2). Turn clockwise to increase pressure and turn anticlockwise to decrease pressure. 6. Repeat steps 3 to 5 until the accumulator has the right pressure. 7. Open and close the drainage plug (3), and recheck the pressure.

33/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

3.8

3 MEASUREMENTS AND ADJUSTMENTS

Measuring and setting the brake pressure switch 1. Connect a pressure gauge (300 bar) to the measuring point (1) marked ACCM. For more information, see Measuring and setting the accumulator pressure (page 33). 3 2 1 4 2. Stop the engine. 3. Switch on the ignition and press the service brake a few times so that the pressure load decreases. The warning symbol lights at 120 bar. 4. When necessary, lift the cover of the pressure switch (4) and adjust the pressure with a screwdriver.

3.9

Measuring the accumulator precharged pressure 1. Connect a pressure gauge (300 bar) to the measuring point ACCM (1).

3 2 1 4 2. Stop the engine. 3. Press the service brake repeatedly. The pressure decreases. 4. The pressure drops immediately from 100 bar to zero bar. This indicates that the accumulator pre-pressure is 100 bar. If the pressure goes below 95 bar before it drops to zero bar, this indicates that the accumulator pre-pressure is too low.

NOTE

3.10

The accumulator is precharged with 100 bar. The precharged pressure can vary depending on the surrounding temperature.

Measuring and setting the parking brake pressure 1. Check the accumulator pressure as set in preceding procedure.

34/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

3 MEASUREMENTS AND ADJUSTMENTS

2. Connect a pressure gauge (300 bar) to the measuring point (5) marked PRM on the accumulator charging valve.

5

6

3. Start the diesel engine and let it idle. 4. Read the pressure. Check that the pressure is 110 bar. 5. If necessary, adjust the parking brake pressure setting on the adjusting screw (6). 6. Turn clockwise to increase the pressure and turn anticlockwise to lower the pressure.

3.11

Adjusting the parking brake The following adjustment controls the application of the parking brake to make engagement of the brake softer. This function is only included on smaller machines. 1. Screw the restrictor and non-return valve (7) to its bottom position and open it 1/4th turn.

7

2. Slowly run the machine forward and apply the parking brake. 3. The brake should engage softly and not cause the machine to grind to a halt.

NOTE

The more screwed in the valve is, the softer the parking brake engages.

35/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

3.12

3 MEASUREMENTS AND ADJUSTMENTS

Measuring the steering pressure 1. Connect a pressure gauge (300 bar) to the test point (1) on the load signal wire of the control pump.

1

2. Start the diesel engine. 3. Steer to the end position and hold. 4. Read the pressure (180 ... 200 bar).

3.13

Adjusting the steering priority valve (older machines only) 1. To adjust the pressure, remove the hose (2) and turn the adjusting screw inside the valve with a hex key (3) (7/32 in).

3

3.14

2

Adjusting steering priority valve (new machines only) 1. Loosen the hydraulic hose that is connected to the pressure regulator.

36/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

3 MEASUREMENTS AND ADJUSTMENTS

2. Screw out the pressure regulator (4).

4

3. Use a screwdriver to turn the adjusting screw (5) on the pressure regulator (4).

4 5

4. One half turn corresponds to a pressure change of about 40 bar. 4.1 Turn clockwise to increase the pressure. 4.2 Turn counterclockwise to decrease the pressure. 5. Tighten the pressure regulator (4). 6. Connect the hydraulic hose to the pressure regulator. 7. Check and measure the pressure. For more information, see Measuring the steering pressure (page 36).

37/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

3.15

3 MEASUREMENTS AND ADJUSTMENTS

Setting the restrictor and non-return valve 1. Tighten the restrictor and non-return valve (6) mounted on the load signal line of the priority valve and lock it with the Allen screw.

6

2. Check that the restrictor and non-return valve (6) is correctly tightened as follows: 2.1 Connect a pressure gauge (300 bar) to the load signal line on the pump connected to the priority valve and turn the steering wheel to its end position. 2.2 The pressure increases to 180–200 bar. 2.3 Let go of the steering wheel and note the pressure drop. Correctly adjusted, the pressure should be gone within 5-10 sec. 2.4 If the pressure drops faster, the restrictor and non return valve is not tightened enough. 2.5 If the pressure is dropping slowly the valve is tightened too much.

3.16

Measuring and adjusting the attachment pressure (ECB) On ECB machines, the L90 valve is equipped with a pressure reducer that is set to 140 bar. The setting does not normally need to be changed. 1. Connect the pressure gauge to the test point (1) on the attachment. 2

1

2. To build up the pressure (140 bar), maneuver the attachment to 20 feet. Throughout the entire adjustment procedure, keep this function activated. 3. Break the plastic seal of the L90 valve.

38/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

3 MEASUREMENTS AND ADJUSTMENTS

4. Adjust the pressure reducer ECB90 (3) or ECB 80 (4).

3

5. Check that the pressure is 140 bar. 4

6. If a whistling noise comes from the attachment by-pass (2) once at the 20 foot position, screw it in until the whistling stops and then turn an extra half turn.

3.17

Measuring and adjusting the attachment pressure (gantry) 1. Connect a pressure gauge to the test point (1) on the attachment.

1 2. To build up the pressure (140 bar), maneuver the attachment to 20 feet. Throughout the entire adjustment procedure, keep this function activated. 39/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

3 MEASUREMENTS AND ADJUSTMENTS

3. Check that the pressure is 140 bar. 4. Adjust the pressure on the pressure reducer (2) in the chassis.

2

40/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

4 TROUBLESHOOTING

4

TECHNICAL MANUAL

TROUBLESHOOTING

41/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

TECHNICAL MANUAL

4 TROUBLESHOOTING

42/42 X150366en / B / 18 Jan 2016 TM Hydraulic System FLT.01en

Copyright © (2014) Konecranes Lifttrucks. All rights reserved.

www.konecranes.com

Corporate HQ Region EMEA HQ Hyvinkää, Finland

Region Americas HQ Springfield, Ohio

Region APAC HQ Shanghai, China

Main production sites Sales and service locations

This document and the information contained herein, is the exclusive property of Konecranes Lifttrucks and represents a non-public, confidential and proprietary trade secret that may not be reproduced, disclosed to other parties, altered or otherwise employed in any manner whatsoever without the express written consent of Konecranes Lifttrucks. © 2014 Konecranes Lifttrucks. All rights reserved. ‘Konecranes’, ‘Lifting Businesses’ and C are either registered trademarks or trademarks of Konecranes Lifttrucks.Copyright © (2014) Konecranes Lifttrucks. All rights reserved.