C11-Schindler-MX-GC Release 4 MRL. Basic Maintenance Tasks [PDF]

OTIS - EMEA NON OTIS FIELD MANUAL LIFT MAINTENANCE BASIC MAINTENANCE TASKS BMT Version: 1.0 Date :June-2019 Page :

34 0 2MB

Papiere empfehlen

![C11-Schindler-MX-GC Release 4 MRL. Basic Maintenance Tasks [PDF]](https://vdoc.tips/img/200x200/c11-schindler-mx-gc-release-4-mrl-basic-maintenance-tasks.jpg)

- Author / Uploaded

- ElputoAmo XD

Datei wird geladen, bitte warten...

Zitiervorschau

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 1/26

SCHINDLER Eurolift with MX-GC Release 4

BASIC MAINTENANCE TASKS The purpose of this manual is to provide to the service mechanics the procedures for perform the main operations to be done during the regular maintenance visits, including code tests, in Non OTIS units. Only the relevant operations (those which must be done following a special procedure) are described. If during the maintenance operations in this model you find any task that can’t be done following the OTIS procedures and is not described here, please contact with EMEA Non OTIS Support Center ([email protected]). According to EN81 standard, installer must provide an instruction manual of the lift. This manual includes detailed information about maintenance tasks and code tests procedures. Please, request this manual to customer. All jobsite work activity must be in full compliance with Otis World Wide Jobsite Safety Standards (WWJSSS). When carrying out this procedure particular consideration should be given to control of the elevator, LOTO, hoisting and rigging, ensuring public safety (signs and barriers), working in close proximity of unguarded rotating equipment (sheaves) and the wearing of appropriate PPE (hand gloves, etc.). It is required that the mechanic(s) carrying out the repair complete the appropriate JHA for the task at hand to familiarize themselves with the work environment. If you are unsure of the WWJSSS standards in regard to the work task at hand, immediately stop work and refer to your Supervisor.

OTIS Elevator Cardinal Rules ALWAYS

use fall protection when a fall hazard exists.

ALWAYS

lock and tag out equipment when power is not required.

ALWAYS

control live electricity and rotating equipment when working within close proximity of the hazard.

ALWAYS

establish and maintain control of the elevator prior to accessing/egressing the hoistway, working on the car top, and in the pit.

ALWAYS

follow proper jumper procedures.

ALWAYS

use certified and inspected hoisting and rigging equipment.

NEVER

ride the car top with the elevator in normal operation.

NEVER

work above or below others when working in the hoistway.

No team members are to use the tools, materials, or methods described in this document without reading, following, and understanding the document prior to the commencement of the work or task.

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 2/26

SCHINDLER Eurolift with MX-GC Release 4

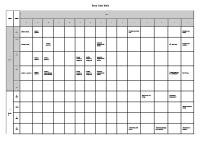

SUMMARY A. GENERAL INFORMATION 1. 2. 3. 4. 5. 6. 7. 8. 9.

GENERAL DESCRIPTION OF THE PRODUCT BOARDS LOCACTION AND CONNECTION OVERVIEW GENERAL DESCRIPTION OF THE EMBEDDED USER INTERFACE TOP OF CAR ACCESS PROCEDURE PIT ACCESS PROCEDURE SPECIAL TOOLING REQUIRED FOR MAINTENANCE HOW TO MAKE CALLS FROM THE LANDING PANEL HOW TO DISABLE DOOR OPERATIONS LOCK OUT OF MAIN ELECTRICAL SWITCHES

3 4 5 5 7 7 8 8 8

B. MAINTENANCE TASKS 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14.

ROPES INSPECTION HOW TO CHECK LOADWEIGHING DEVICE TEST OF EMERGENCY CAR LIGHT AND ALARM TEST OF MANUAL RESCUE OPERATION TEST OF CAR SAFETY GEAR WITH EMPTY CAR AND LOW SPEED TEST OF FINAL LIMITS (KNE) ADHERENCE TEST RUN TIME LIMIT TEST (DDP) INSPECTION LIMIT SWITCH BRAKE TEST: EMPTY CAR UPWARDS STOPPING DISTANCE BRAKE MAINTENANCE ONE SHOE BRAKING TEST UPWARDS VF FAN TEST POSITIONING SYSTEM MAINTENANCE

9 9 9 10 11 11 12 13 13 13 15 18 20 21

C. BASIC CALLBACKS SOLUTION 1. 2. 3. 4.

HOW TO CHECK THE SAFETY CHAIN FROM LANDING PANEL HOW TO RESET PERMANENT ERROR HOW TO RESET LIFT FROM TOP OF THE CAR HOW TO CHECK ERROR LOG

22 23 24 24

D. MAIN ADJUSTMENT PROCEDURES 1. 2. 3. 4. 5. 6.

LEARNING RUN ADJUST FLOOR LEVELS LOADWEIGHING DEVICE CALIBRATION VF DRIVE REPLACEMENT GCIOB BOARD REPLACEMENT LON NODE REPLACEMENT

EMEA FIELD SERVICE, SUPPORT TO NOE

25 25 25 25 26 26

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT A. 1.

Version: 1.0 Date :June-2019 Page : 3/26

SCHINDLER Eurolift with MX-GC Release 4 GENERAL INFORMATION

GENERAL DESCRIPTION OF THE PRODUCT

Eurolift is a model from Schindler for both modernizations and new installations. It was released around 2000 and was discontinued around 2014, replaced by Schindler 5500. This manual is focused on the machine room less version of the product but most of the contents apply also to the machine room version.

LWD at dead hitch end

VF drive VF11/22/33/44 BR (not regenerative)

Gearless machine (PMS420, PMS230, SM250)

Foldable platform (access to Top of Car not allowed)

Typical COP

Typical VF door drives (LUST, IDD3000)

Controller cabinet for Miconic MX-GC at top landing

Note: Pictures show the typical components but several others can be used.

Typical landing fixtures (also allows BIO devices and Schindler’s destination dispatch Miconic 10) EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

SCHINDLER Eurolift with MX-GC Release 4

BMT 2.

Version: 1.0 Date :June-2019 Page : 4/26

BOARDS LOCATION AND CONNECTION OVERVIEW

Positioning system (on top of car) KUET/RKUET

Hoistway headroom

Landing cabinet

AGSI/ALSIS

VF Drive

Machine ASIXA GCIOB RECPCB

LONIC PDB (Power Distribution Board)

BCM (Brake Control Module)

Top of Car LONIBV

LONLMDMS (Load Weighing Device)

LONCOP

NWPB5

NWPB5

COP LONDY

NWDY

LONDI

NWDI

NWPB5

Digital signals NWPBU

LON-C Bus

LONCUS

LON-S Bus NWSI Bus

NWPBD NWDB

RS-422 Bus

LONPBD NWSL

Detailed explanations can be found in training documents at EMEA FOD website.

Hoistway EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT 3.

Version: 1.0 Date :June-2019 Page : 5/26

SCHINDLER Eurolift with MX-GC Release 4

GENERAL DESCRIPTION OF THE EMBEDDED USER INTERFACE

ASIXA board includes a user interface which provides useful information to service mechanic. Communication info

Lift identification zone

CCS

COM ETHERNET

SK

Chip Card

T1 T2 T3A T3B T4 T5

BATT

Rx

Lift ID

NGL Tx

JMOF selector (installation mode)

LON

1↔ 0

ESC

Safety chain checking points

DUEISK-A LR-U

NGO

Power supplies info

2NG O

LUET

LTRT

JMOF

LR-D

▲

▼

Car position and door zone

OK

Service tool (SMLCD) (SMLCD) For detailed information about this user interface, please check “Field Manual Schindler MX-GC Release 4. Service interface manual” in EMEA FOD website. 4.

TOP OF CAR ACCESS PROCEDURE

In Eurolift model the machine interferes with the car overrun. Therefore, it is not allowed to access to top of the car. Instead of this, a foldable platform has been installed for maintenance purposes. This platform can be unfolded from within the car and allows the mechanic to work on the hoistway items and travel in inspection mode in a non-hazardous position. Platform has safety contacts which make not possible to travel in normal when platform is unfolded. The following is a schematic description about how to unfold the platform.

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 6/26

SCHINDLER Eurolift with MX-GC Release 4

Due to this special situation (access to top of car not allowed, safety contacts in the platform), a special procedure for getting access to the platform and move the lift in inspection has been developed. The procedure is as follows: Access to platform must be carried out from the landing where the controller is located (typically, the top floor) because JRH switch (equivalent to ERO in OTIS) will be used during the process. a) Make a hall call from the landing where the controller is located. b) Make two car calls, one to the floor immediate below and the other to the bottom floor (call to bottom floor assures that the downwards travel command is hold during the process and, thus, the efficiency of the test is improved). c) Open the landing door when top of the car is approximately at the landing level. Make a hall call and wait about 10 seconds (this is for testing the landing door lock of the access floor). d) Close the door and make a hall call again to the access floor. e) Open the controller cabinet and, once the car doors are fully opened, switch JRH. By doing this, lift is not in Normal mode but in the equivalent to ERO mode. f) Make a car call. Car should not be registered. Therefore, JRH is working and lift is not in normal but under the control of the mechanic.

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 7/26

SCHINDLER Eurolift with MX-GC Release 4

g) Get access to car and unfold the platform (be cautious and hold the platform during the process because, even when the platform has a latch for preventing it to fall down, it could get released and fall free). Put the platform on the working position unfolding and securing the ladder and go back to the controller. h) Switch JRH to Normal and make a car call. Call should not be registered, what means the contacts of the platform avoid the lift to work in normal with platform unfolded. Switch back JRH to “ERO” position and close the controller cabinet. i) Jump to the platform and put the lift in Inspection mode on top of the car. j) Press down button on Inspection Box. Doors should begin to close. Release the button when doors are halfway to the closed position. (This verifies the inspection box works properly). k) Press Stop push button on Inspection Box and, again, press the down button in inspection. Doors should not move, what means the Stop push button is working properly. l) Release Stop and check the performance of the lift in inspection mode by making short runs downwards first and upwards afterwards. Once checked both directions work properly, it is allowed to travel in Inspection as needed. m) Remember to push Stop every time the car is stopped. EXITING FROM THE PLATFORM a) Travel in inspection mode to the top floor (or the top where the controller cabinet is located) and stop the car at door zone trying to not overpass the landing level. Press Stop on top of the car. b) Press the Stop of the door drive in order to cut the power off to the door drive and make possible to open the doors manually. c) Put the Inspection switch back to Normal and release the STOP push button. d) Release the Stop of the door drive, go down from the platform, open the controller cabinet and confirm the JRH switch is in “ERO” position. e) Fold the car platform and put it back to its normal position, checking carefully that it is properly fitted. f) Switch JRH to Normal position and check the lift works properly. 5.

PIT ACCESS PROCEDURE

There is nothing special in Eurolift regarding the pit so the OTIS procedure according with the WWJSS can be followed. 6.

SPECIAL TOOLING REQUIRED FOR REGULAR MAINTENANCE

Both Service Tool (SMLCD) and ERO box (JRH according with Schindler terminology) are included on the ASIXA board. Therefore, the only tool needed for the regular maintenance tasks is the bolt for blocking partially the brake of the machine in order to perform the one shoe braking test. This bolt can be found usually inside the controller cabinet.

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 8/26

SCHINDLER Eurolift with MX-GC Release 4

Figure 1: Locking bolt for PMS230 machines. Part number: Unknown. Figure 2: Locking bolt for PMS420 machines. Part number: SHR-128613

Figure 1

7.

Figure 2

HOW TO MAKE CALLS AND DOOR COMMANDS FROM THE LANDING PANEL

It is possible to make car calls by using the embedded service tool (SMLCD). For doing so, from the main screen press OK and, once the menu tree is shown, use the arrows for navigate and go to the option COMMANDS Car Calls. Destination floor and landing (when double entrance) have to be introduced. After confirmation by pressing OK, car call is performed. This menu can be accessed from any other menu by pressing simultaneously the keys ESC and OK. It is also possible to make floor calls in the menu option COMMANDS Floor Calls. Floor and landing (when double entrance) from where the call is made have to be introduced and whether the call will be an up or a down call. After confirmation by pressing OK, floor call is performed. In order to make door operations, go to COMMANDS Doors. For lifts with double entrance, front or rear landing can be selected and, once the landing has been chosen, the system allows opening or closing it. After confirmation by pressing OK, door operation is performed. 8.

HOW TO DISABLE DOOR OPERATIONS

In Order to disable door operations (DDO in OTIS acronyms) SMLCD can be used. From main screen, press OK and, once the menu tree is shown, use the arrows for navigate and go to the option COMMANDS Special Trips KFM and press OK. KFM is a special mode of operation of the lift that, when enabled, makes the lift to don’t perform door operations nor attend calls. Service mechanic can send the car to the top and bottom floors with the commands DFM-U and DFM-D (in the same menu than KFM). Car calls without door operation can be done as well from the SMLCD. 9.

LOCK OUT OF MAIN ELECTRICAL SWITCHES

Note: this is for reference only. Check wiring diagram of your jobsite. The main switches located in the controller cabinet and that could be necessary to lock out are: JH (3 phases main switch) Disconnects everything but the lighting system. SIS disconnects brake module, door motor, NGL power supply and governor remote tripping coils. SIL and JFIL Car lighting and sockets (in controller cabinet, pit and headroom if any). SIBS Hoistway lighting. JHO disconnects optional power supplies (NGO). EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 9/26

SCHINDLER Eurolift with MX-GC Release 4

B. MAINTENANCE TASKS 1. ROPES INSPECTION Schindler’s Eurolift uses standard steel traction ropes so they can be inspected following the OTIS procedures for these tasks. 2. HOW TO CHECK LOAD WEIGHING DEVICE Load information is shown directly on the main screen (Status Lift) of the SMLCD. It is updated in real time so putting load in car should have immediate effect on the value shown in this screen (value is shown as a percentage of the nominal load). If nothing is shown in this position of the screen, it means load weighing device is disabled. If load indication doesn’t match with load in car, recalibrate the load weighing device (procedure is described in SMLCD User’s Manual). In order to check the overload performance, do as follows:

Put load in car and check the load percentage value shown on the screen (let’s call it X).

In menu Parameters Drive Settings, check the parameter Nominal Load (let’s call it Y)

Change the Nominal Load to a value X∙Y/110 and press OK. Go back to main screen (press at the same time the keys ESC and ▲) and check the value is now 110%. The lift should be out of service, the overload buzzer sounds and overload indication is shown on COP.

Set back the Nominal Load parameter to its previous value and check the load indication is according with the load in car.

3. TEST OF EMERGENCY CAR LIGHT AND ALARM Make a car call to the top landing and, once the doors are opened, put the lift in JRH (equivalent to ERO) mode. Switch off JFIL in the controller cabinet and check the emergency car light is in operation. Press the alarm button in car and check the buzzer sounds and phone call with the call center is established. Check the performance of microphone and loudspeaker in COP are good. Check as well that proper lights in car for “Alarm sent” and “Help is coming” turn on. Switch on JFIL, put JRH back in Normal position, and check the lift works in Normal mode. Wait a few minutes in order to check the alarm has been properly acknowledged and, therefore, the communication device doesn’t try to call again to the call center.

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 10/26

SCHINDLER Eurolift with MX-GC Release 4

4. TEST OF MANUAL RESCUE OPERATION Depending on the type of machine, the rescue operation is carried out manually with a lever connected by a Bowden cable to the machine or electrically by supplying the brake directly from a battery through two buttons (DEV and DEV1) in the controller cabinet.

Manual rescue device

Electric rescue device

The general procedure is as follows: Switch off main switch (JH) in controller cabinet. All devices (except lighting circuit) are disconnected but ASIXA board remains powered by the battery included in the controller. If this is not the situation, replace the battery. Press arrows keys ▲ and ▼ at the same time in the SMLCD. Leds LR-U, LUET and LR-D should turn on at the same time (this allows to be sure that, when performing manual rescue operation, information about door zone and movement direction is available).

LR-U LUET LR-D

Check the car position information in the screen: while powered by battery, SMLCD screen shows on the bottom line the distance (in cm) from the current car position to the nearest landing (+ sign means the nearest landing is above the car position, - means the nearest landing is below). The internal level of the nearest floor is shown on the second row. Release the brake using the lever or pressing DEV and DEV1 buttons at the same time. Check the position (with the indication of the bottom line of SMLCD) and direction (LR-U is on when going up, LR-D is on when going down) of the car. If speed reaches 0,3 m/s a buzzer sounds (WARNING: Speed is not automatically limited so immediately release the lever/buttons if car speeds up too much). Once the door zone is reached (LUET led turns on), release the lever/buttons, open the door and rescue the passengers. Check that instructions about the rescue procedure are available on the cover of the controller cabinet.

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 11/26

SCHINDLER Eurolift with MX-GC Release 4

5. TEST OF CAR SAFETY GEAR WITH EMPTY CAR AND LOW SPEED Make a car call to the top landing. Check there is nobody in car. Leave the car to open and close the doors and then put the lift in JRH mode. Move the car downwards in JRH mode and, at the desired moment (car speed can be checked with SMLCD), engage the safeties by pressing the button DBV located in the controller cabinet. Car stops and error message is shown in SMLCD. Move again the car downwards in JRH. Car should keep stopped (speed shown in SMLCD is 0.0 m/s but machine should keep rotating (noise from the machine can be heard from the top landing). Release the JRH down direction button. Open the landing door and check the position of the car. Close the door and try to move the car downwards again for a 4-5 seconds. Open again the landing door and check the car didn’t move. Put the lift in Normal mode and check the safety chain is opened (at least leds T3B, T4 and T5 should be off). Switch back to JRH. Move the car upwards in JRH mode in order to disengage the safeties. The contact in car for the safety gear (KF) should reset automatically. It could be necessary to reset the governor contact (KBV) and/or the governor tension device contact (KSSBV). Reset the error: with the lift in JRH, press Stop (JHM), press and release both upwards and downwards buttons at the same time, release JHM and switch JRH to Normal. Car should make a correction run (synchronization run according with Schindler naming) to the nearest floor. Check the proper performance. 6. TEST OF FINAL LIMITS (KNE) MX-GC control system includes a Test function (KNE) which moves the car from the top/bottom landing towards the hoistway end for an adjustable distance. Setting this distance longer than the KNE actuation distance, the performance of this contact can be checked. The procedure would be as follows: Make a car call to the top landing. Check there is nobody in car. Log in SMLCD (go to menu Login in SMLCD and key in the password. Default password is ABCD). Leave the car to open and fully close the doors and then put the lift in KFM mode (with SMLCD, go to Commands Special trips KFM On). Using the SMLCD, go to menu TESTS Acceptance Tests KNE Test. SMLCD asks for the distance we want to move the car. Key in a distance between 120 mm and 200 mm and press OK. Lift will move towards the hoistway ends for the distance we keyed in (control system automatically detects the car position; if it is located at the top landing, movement is upwards; if it is located at the bottom landing, movement is downwards). When the limit switch (KNE-U) opens the contact of the safety chain, car stops and distance from the landing level is shown. Check safety chain has opened at the proper checking point (T1 and T2 led are both on, all the others are off). EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 12/26

SCHINDLER Eurolift with MX-GC Release 4

Put the lift in JRH mode and move the car towards the landing level. Put the lift back to Normal and check the proper performance. For checking the bottom limit switch (KNE-D), send the car to the bottom landing using the SMLCD and repeat the process. Once the tests have finished, put the lift back in service (with SMLCD, go to Commands Special trips KFM Off). 7. ADHERENCE TEST The purpose of this test is to check that ropes slip over the traction sheave when moving the car upwards in ERO mode while counterweight is on its buffers. If car is lifted in this condition, there is a safety risk and containment actions have to be taken. The procedure is as follows: Make a car call to the top landing. Check there is nobody in car. Log in SMLCD (go to menu Login in SMLCD and key in the password. Default password is ABCD). Leave the car to open and fully close the doors and then put the lift in KFM mode (with SMLCD, go to Commands Special trips KFM On). Using the SMLCD, go to menu TESTS Acceptance Tests Traction (t19) Test. Screen shows “Begin”. Put the lift in JRH (ERO) mode and move the car upwards until counterweight strikes the buffers and ropes slip over the traction sheave. Drive will automatically block the lift after about 2 seconds of slippage. SMLCD will show the distance of slippage in cm. If test is successful, “1” will be shown on the SMLCD; if it is unsuccessful, “0” will be shown. If it were necessary to check the slippage directly, it is possible to watch the traction sheave while moving the car upwards in inspection mode from the foldable platform. For doing this, it is required to bridge the contact KWL in the safety chain and place the SKS shunt on ASIX board as well (it shunts the limit switches). Normally there is a set of connectors in the controller cabinet for making these bridges.

Move the car downwards until the top landing level is reached, remove the bridges, switch from INS to normal on top of the car, fold the platform and put JRH switch in Normal mode. Check the lift works properly by making car calls from SMLCD.

Put the lift back in service (with SMLCD, go to Commands Special trips KFM Off). EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 13/26

SCHINDLER Eurolift with MX-GC Release 4

8. RUN TIME LIMIT TEST (DDP) The purpose of the test is to check the travel limit protection is enabled and working: if car has not reached the destination landing after a defined time (adjustable) from the run command, an emergency stop is performed in order to protect the motor and avoid slippage which could damage sheave and ropes. The procedure is as follows: Make a car call to the top landing. Check there is nobody in car. Log in SMLCD (go to menu Login in SMLCD and key in the password. Default password is ABCD). Leave the car to open and fully close the doors and then put the lift in KFM mode (with SMLCD, go to Commands Special trips KFM On). Using the SMLCD, go to menu TEST Acceptance Tests Trip Time (t37) Test. Once OK key is pressed, SMLCD request the desired limit time. Key it in (in seconds) and press OK. Screen shows “Begin”. Make a Car Call (pressing simultaneously keys ESC and OK the car calls screen is shown in SMLCD). Car begins the travel and, once the limit time has elapsed, an emergency stop is performed. Display shows “Success”. Trip limit time automatically is set back to its previous value. Reset the fatal error and put the lift back in service (with SMLCD, go to Commands Special trips KFM Off). 9. INSPECTION LIMIT SWITCH Miconic MX-GC control system has an absolute encoder on top of the car for measuring the car position. Information about the car position is not lost not even after main power down. Therefore, lift never needs a correction run so equivalent signals to 1LS and 2LS are not used. It is used neither an equivalent to 5LS or 6LS signals for inspection run limits: when moving downwards in inspection, car stops at landing level; when moving upwards, in order to prevent the mechanic to hit with the machine, car stops at a distance that can be set with the parameter KSERE_Dist. (in menu Parameters Traction General; requires Login first). In order to check the proper setting of this parameter, once car is at the top landing, unfold the maintenance platform and move upwards in Inspection mode until the car stops. Check that no more upwards runs are allowed. From this position, check the distance from the platform to the machine. It should be about 2000 mm in order to prevent the mechanic to hit with the machine. If KSERE_Dist requires readjustment, place the platform at the desired height and measure the distance between the platform and the top landing door sill. Key in this data as new setting for KSERE_Dist. In order to permanently store the new setting in EEPROM, in SMLCD go to Commands Drv. End Commision and press OK (requires Login first). 10. BRAKE TEST: EMPTY CAR UPWARDS STOPPING DISTANCE The purpose of this test is to check the machine brake is able to stop the car when travelling at nominal speed and with a deceleration not higher than the one stated in the code. In order to do this, MX-GC control system includes a Test (Brake Test) which shows the deceleration of the car when an emergency stop is performed. The procedure is as follows: EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 14/26

SCHINDLER Eurolift with MX-GC Release 4

Make a car call to the top landing. Check there is nobody in car. Log in SMLCD (go to menu Login in SMLCD and key in the password. Default password is ABCD). Leave the car to open and fully close the doors and then put the lift in KFM mode (with SMLCD, go to Commands Special trips KFM On). Use the SMLCD for sending the car to the bottom landing. Using the SMLCD, go to TESTS Acceptance Tests Brake Test (t14). Screen shows “Running”. Make a call to the top landing (pressing simultaneously keys ESC and OK the car calls screen is shown in SMLCD). When the car reaches the nominal speed (current speed can be checked in the SMLCD display) press JHM button (Stop button in ASIX). Emergency stop is performed and SMLCD shows the deceleration of the car during this stop. For PMS230 machine, deceleration should be at least 1.000 mm/s2. For PMS420 machine, deceleration should be at least 500 mm/s2. For other machines, if there are no manufacturer data about deceleration, it is normally accepted that it to be between 600 and 800 mm/s2. Release the JHM button. Car should perform a correction run to the nearest landing. Once the tests have finished, put the lift back in service (with SMLCD, go to Commands Special trips KFM Off).

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 15/26

SCHINDLER Eurolift with MX-GC Release 4

11. BRAKE MAINTENANCE PMS230 machine: Brake torque cannot be readjusted. If brake tests fail, replace the brake. Airgap checking and adjustment:

Make the counterweight to rest on its buffer and unfold the maintenance platform.

Remove the rubber cover for dust (1).

Using a gauge, check the airgap between the disk of the armature (5) and the magnet (3). The proper gap is 1 mm.

For readjust: o

Loosen the safety nut (2), accessible from the sheave side, and the nut of the armature (4).

o

Using an Allen key with the central bolt, adjust the airgap. If it is not possible to get an airgap greater than 1mm, replace the magnet.

o

Once a 1mm airgap is achieved, fasten nut (4) and safety nut (2). Put the rubber cover back in place.

o

Repeat the procedure for the other brake.

Brake switches (KB and KB1) checking and adjustment:

Check there are no KB faults logged in the Error Log.

Check with leds KB and KB1 on BCM board that switches change their state when brake opens and drops.

For readjust (in case of fault or switch replacement): o Make the counterweight to rest on its buffer and unfold the maintenance platform. o With brake dropped, loosen the nut (2) and tighten the bolt (1) until the switch (4) is actuated. o Place a 0,4 mm gauge between the bolt (3) and the contact (4) and loosen the bolt until the switch is deactivated. o Fasten the nut (2). o Repeat the same with the other brake switch.

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 16/26

SCHINDLER Eurolift with MX-GC Release 4

PMS420 Machine: Brake torque cannot be readjusted. If brake tests fail, replace the brake. Airgap checking and adjustment:

Make the counterweight to rest on its buffer and unfold the maintenance platform. Before checking the airgap, confirm that the safety nut (5) is tightened. Open the brake and check there is no airgap (3) between the plate of the armature (7) and the magnet (2). (Note: a small partial airgap could be normal but if there is airgap in the whole circumference the brake must be replaced). Release the brake. Use a gauge for checking the airgap is above 0,3 mm and below 0,4 mm. For readjusting the airgap: o Loosen the safety nuts (5). o Adjust alternatively the two bolts (6) until the desired airgap is achieved. o Tighten the safety nuts. Repeat the same operation with all the brakes of the machine (there can be between 2 and 4 brakes)

Brake switches checking and adjustment: Check there are no KB faults logged in the Error Log. Check with leds KB and KB1 on BCM board that switches change their state when brake opens and drops. Put a 0,05 mm gauge in the airgap between magnet and armature and open the brake. The microswitch must change its state. (It is recommended to use a multimeter because it is not always possible to hear the click). Put a 0,15 mm gauge in the airgap and open the brake. The microswitch shouldn’t change its state. For readjusting: Remove the cover (4 of the airgap checking figure). With brake dropped, loosen the nut (6) and the bolt (7). Put a 0,05 mm gauge in the airgap and open the brake. Tighten the bolt until microswitch changes its state. Replace the gauge by a 0,15 mm one; open the brake and check the microswitch doesn’t change its state. Tighten the nut. Repeat the process with the other brakes. EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 17/26

SCHINDLER Eurolift with MX-GC Release 4

SM250 machine: Brake torque cannot be readjusted. If brake tests fail, replace the brake. Airgap cannot be adjusted, it can only be checked. The procedure is as follows:

Make the counterweight to rest on its buffer and unfold the maintenance platform.

Using a gauge, check the airgap between the disk and the magnet while the brake is dropped. The proper gap is between 0,2 and 0,6 mm.

Measure the airgap in three different points of the circumference and take the maximum value. If due to wear the airgap is over 0,6 mm in any of the two magnets, the whole brake must be replaced.

Brake switches (KB and KB1) checking and adjustment:

Check there are no KB faults logged in the Error Log.

Check with leds KB and KB1 on BCM board that switches change their state when brake opens and drops. Put a 0,15 mm gauge close to the bolt in the corresponding airgap. Open the brake and tighten the adjusting screw until the conmutation point is reached (it is suggested to use multimeter for checking the commutation point because the click of the contact is not always hearable).

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 18/26

SCHINDLER Eurolift with MX-GC Release 4

12. ONE SHOE BRAKING TEST UPWARDS The purpose of the test is to confirm that braking operation with only one shoe is according with the EN81-1 standard: in this condition, when car is travelling, brake should be able to keep the speed below the nominal speed. When car is stationary, it should be able to keep it in place. The procedure for this test depends on the type of machine. Procedure for PMS230 machine:

Make a car call to the top landing. Check there is nobody in car and put the lift in JRH mode. Unfold the platform for getting access to the machine.

Block one of the manual rescue levers by inserting the test pin in the holes (1) and (2).

Get out of the hoistway and fold the platform.

Release the brake manually. Check that car doesn’t move.

Log in SMLCD (go to menu Login in SMLCD and key in the password. Default password is ABCD).

Leave the car to open and fully close the doors and then put the lift in KFM mode (with SMLCD, go to Commands Special trips KFM On).

Using SMLCD, make a car call to the bottom landing.

Using the SMLCD, go to TESTS Acceptance Tests Brake Test (t14). Screen shows “Running”.

Make a car call to the top landing and, as soon as the car reaches the nominal speed, hold the brake released manually and press STOP (JHM). Emergency stop is performed and SMLCD shows the deceleration of the car during this stop. Check in SMLCD that speed decreases from nominal speed (or, at least, that it doesn’t increase). If speed increases, immediately release the lever.

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 19/26

SCHINDLER Eurolift with MX-GC Release 4

Warning: Make the test with the car as far as possible from the top landing in order to prevent the counterweight to hit on its buffers at high speed in case of test failed.

Release the lever, and, if test finished ok, release the Stop button (JHM). Make a car call to the top floor, put the lift in JRH mode and unfold the platform. Get access to the machine and remove the pin.

Repeat the test with the other brake side.

Once the tests have finished, put the lift back in service (with SMLCD, go to Commands Special trips KFM Off).

Procedure for PMS420 machine:

Make a car call to the top landing. Check there is nobody in car and put the lift in JRH mode. Unfold the platform for getting access to the machine. Block one of the manual rescue levers by inserting the test pin (6) in the holes (7) and (8). Get out of the hoistway and fold the platform. Release the brake manually. Check that car doesn’t move. Log in SMLCD (go to menu Login in SMLCD and key in the password. Default password is ABCD). Leave the car to open and fully close the doors and then put the lift in KFM mode (with SMLCD, go to Commands Special trips KFM On). Using SMLCD, make a car call to the bottom landing. Using the SMLCD, go to TESTS Acceptance Tests Brake Test (t14). Screen shows “Running”. Make a car call to the top landing and, as soon as the car reaches the nominal speed, hold the brake released manually and press STOP (JHM). Emergency stop is performed and SMLCD shows the deceleration of the car during this stop. It should be at least 150 mm/s2. Check in SMLCD that speed EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 20/26

SCHINDLER Eurolift with MX-GC Release 4

decreases from nominal speed (or, at least, that it doesn’t increase). If speed increases, immediately release the lever. Warning: Make the test with the car as far as possible from the top landing in order to prevent the counterweight to hit on its buffers at high speed in case of failed test. Release the lever, and, if test finished ok, release the Stop button (JHM). Make a car call to the top floor, put the lift in JRH mode and unfold the platform. Get access to the machine and remove the pin. Repeat the test with the other brake side. Once the tests have finished, put the lift back in service (with SMLCD, go to Commands Special trips KFM Off). Note: For PMS420 machines with three brake pads, in order to test the performance of each of the brakes of one side independently, it will be necessary to detach the brake pad under test from the manual rescue system. This can be done as follows:

For testing the upper brake: Remove the locking spring (4) and the pin (6) and link the short connection lever (5) with the long connection lever (2) with the screws (3). For testing the lower brake: Remove the locking spring (4) and the pin (6) from the long connection lever (2) of the lower brake.

13. VF FAN TEST This test allows checking the fan of the VF drive is working properly. In SMLCD, go to Tests VF Test Fan Test (requires Login). During this test, the fan of the VF drive will drive for a few seconds. If it doesn’t work, replace it (a non-working VF fan could lead to damage the VF drive itself).

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 21/26

SCHINDLER Eurolift with MX-GC Release 4

14. POSITIONING SYSTEM MAINTENANCE Positioning system in Miconic MX-GC has a measuring system located on top of the car. There are two different systems: AGSI, which uses a toothed belt and an absolute encoder and ALSIS which uses a magnetic tape and a reader. Toothed belt

Magnetic tape

Encoder Slider Reader

AGSI system: absolute rotary encoder moved by a toothed belt. Proper tension of the belt has to be checked. Low tension could cause position faults; excessive tension could damage the encoder.

ALSIS system: Magnetic reader and magnetic tape. Tension of the tape has to be checked. In addition, check the wear of the slider: if the thickness is less than 2mm, it should be replaced.

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 22/26

SCHINDLER Eurolift with MX-GC Release 4

C. BASIC CALLBACKS SOLUTION 1. HOW TO CHECK THE SAFETY CHAIN FROM LANDING PANEL At the top area of the ASIXA board, there is a row with 5 leds (T1, T2, T3A, T3B, T4 and T5). Each of them shows the status of the safety chain on that checking point. Before this checking points there is an overcurrent protection included in ASIXA (if this protection is tripped, red led LUEISK will be lighting; for resetting, press DUEISK-A button). The voltage of the safety chain is 24Vdc but ASIXA board includes an internal regulator which tries to compensate voltage drops in the safety chain contacts. The limit of this regulator is 52 Vdc. If this limit is reached, it is assumed that safety contact is open. So, when using a multimeter for testing the safety chain, expected measurement results will be 24Vdc if safety chain is closed and 52Vdc if safety chain is opened at any point. Note: The following description is generic. It may differ from the one found in some specific jobsites. Please, use it as a reference only. Before shunt any safety contact, check the wiring diagram of the unit. T1 RKPH (Phase relay, option); located between SK1.1 and SK1.2 pins of ASIXA board T2 JHM (stop on ASIXA board) and safety contacts located in pit (governor tension device, stop in pit, ladder, etc); located between SKS.1 and SKS.2 (except JHM). T3A Safety contacts in hoistway which are bridged when lift is in ERO mode (limit switches, buffer switches, overspeed contact on governor); located between SKS.2 and SKS.3. T3B Safety contacts in car (inspection, stop on top of the car, safety gear); between SKC.1 and SKC.3. T4 Door lock contacts of the landing doors; located between KTS.1 and KTS.3. T5 Shunt contacts of landing doors (between KV.1 and KV.2) and car door contact (between SKC.4 and SKC.5). All the connectors for testing the safety chain are located in a row on top of the ASIXA board. When using the tester probes or shunts there is a risk of touching the metal plate of the ASIXA board. So, it is suggested to cover it with isolating tape (see picture below). Connectors for safety chain Isolating tape covering the plate Leds for the checking points of the safety chain

LUEISK led and DUEISK button

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 23/26

SCHINDLER Eurolift with MX-GC Release 4

Equivalence of nomenclature for the main safety contacts OTIS SCHINDLER Description GTC KSSBV Governor tensioner device KLSG Pit ladder PES JHSG Stop in pit KNE-U UDLS Final limit contact KNE-D OS KBV Overspeed contact in governor Buffers KP Buffer SOS KF Safety gear TCI JREC Inspection on top of the car TES JHC Stop on top of the car ERO JRH Inspection in controller STOP ERO JHM Stop in controller DW KV Landing door shunts DS KTS Landing door locks GS KTC Car door lock 2. HOW TO RESET A PERMANENT ERROR When certain faults happen, Miconic MX-GC control system gets blocked in such a way that even if the problem that caused the fault has been removed, the lift remains out of operation. So, it is necessary to reset the lift for put it in operation again. There are different reset options depending on which is the subsystem that caused the problem: Reset of Travel Control: Removes certain blockages caused by problems in the positioning system (i.e. positioning sensors). Procedure: Push Stop (JHM) on ASIX board and put the lift in JRH (ERO) mode. Press simultaneously the Up (JRH-U) and Down (JRH-D) buttons of JRM (ERO) and, afterwards, release Stop. Switch JRM back to Normal.

Reset of the Control System: Restarts the control board.

Procedure: Press reset button on GCIOB board (it may take 2-3 minutes to restart the sytem). Double reset of the Control System: “Deep” reset, clears registers and performs a different restart routine (it may take some minutes to complete). Procedure: Press reset button on GCIOB board and, when it beeps, press the button again. Reset of VF drive: Restarts the VF drive, clearing all the faults related to it which are no longer present. Procedure: Disconnect main switch (JH) for 5-10 seconds and reconnect it. If by doing this the VF drive is not recovered, press reset on the VF drive control board and keep it pressed until all the leds of the board turn on. Then, release the button.

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 24/26

SCHINDLER Eurolift with MX-GC Release 4

3. HOW TO RESET THE LIFT FROM TOP OF THE CAR In order to prevent the mechanic to be trapped on top of the car due to a fault related to the travel control, it is possible to reset the control system from top of the car. Procedure: Lift should be in Inspection mode (JREC switch in JREC position). Push Stop (JHC) on top of the car and, afterwards, press simultaneously Up direction button (DREC-U) and Down direction button (DRECD). Then, release Stop. System should be recovered. 4. HOW TO CHECK THE ERROR LOG MX-GC control system has an error log which keeps stored the historic of faults of the lift. In order to check it, there is an option called Error Log in the SMLCD main menu. This log stores the latest 20 faults of the lift and shows the error code and a short description. For additional information about these codes, check the manual Schindler Miconic TX and MX-GC. Error codes, available in EMEA FOD website.

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 25/26

SCHINDLER Eurolift with MX-GC Release 4

D. MAIN ADJUSTING PROCEDURES 1. LEARNING RUN Learning run is needed when replacing the GCIOB board, the positioning encoder (AGSIS or ALSIS), or when moving any magnet of the positioning system in the hoistway. The procedure is as follows: Put the lift in installation mode by sliding the JMOF selector to the “1” position. Move the car upwards in JRH (ERO) mode until it reaches the top landing level (LUET led on ASIX board is lighting). Log in SMLCD (go to menu Login in SMLCD and key in the password. Default password is ABCD). Go to Commands Special Trips JLF and activate it by pressing OK and confirming. Slide the JMOF selector to the “0” position and turn JRH switch to Normal. Learning run begins automatically and SMLCD shows Learn. The car travels at 0,20 m/s downwards to the bottom floor. Once this floor is reached, car relevels, learning run is finished and lift is in Normal mode. Note: During the learning run, the lift will reach the terminal bottom floor and will slightly overpass it so if the limit switch (KNE-D) is very close to the landing level safety chain will be opened and learning run will be aborted. If this is the situation, shunt temporarily the safety chain between ASIX pins SKS.2 and SKS.3. Once the learning run is finished, remove the shunt. For this purpose, normally a red labelled connector can be found in the controller cabinet. 2. ADJUST FLOOR LEVELS After a learning run it is often necessary to readjust the levelling of car. This can be done with SMLCD, in the option Commands Adj. Floor Level (requires Log In). See Service Interface With SMLCD. User Manual for more details. 3. LOADWEIGHING DEVICE CALIBRATION When loadweighing device LONLMDMS is used, in order to commission it is necessary to perform offset (Empty Car) and gain (Full load, requires 40 to 100% of load in car) calibration procedures. These procedures can be done with SMLCD in the option Commands LMS Commission menu. See Service Interface With SMLCD. User Manual for more details. 4. VF DRIVE REPLACEMENT When a new VF drive is placed, once all the wiring is done, in order to commission the new drive it is necessary to perform the following actions: Double reset the GCIOB board. This transfer the parameters from the GCIOB board to the VF drive. Perform DC-Link Test T0 Perform Current Loop Test T1 Perform Direction Test (geared machines) or Zero Position Test T3 (gearless machines) Save changes with Commands Drv. End Commission.

EMEA FIELD SERVICE, SUPPORT TO NOE

OTIS - EMEA

NON OTIS FIELD MANUAL

LIFT MAINTENANCE

BASIC MAINTENANCE TASKS

BMT

Version: 1.0 Date :June-2019 Page : 26/26

SCHINDLER Eurolift with MX-GC Release 4

5. GCIOB BOARD REPLACEMENT When a new GCIOB board is placed, it is better, if possible, to keep the same EEPROM (parameters) and the same FSIMM board (software). If these both components are kept, the lift should work when powered up without further action. If any of the components (EEPROM or FSIMM board) is replaced, a new commisioning of the lift is required. This means to perform, as minimum, a learning run, adjust floor levels and lwd commisioning. In all cases it will be necessary to perform a node tree update: with SMLCD, go to Commands Freeze Node Tree. 6. LON NODE REPLACEMENT After any LON node replacement (LONIC, LONIBV, LONCUS, etc.), it will be necessary to perform a node tree update: with SMLCD, go to Commands Freeze Node Tree.

EMEA FIELD SERVICE, SUPPORT TO NOE